Single-mouth pipe liquid-solid type two-chamber non-PVC film soft-bag large-infusion automatic production line

An automatic production line and single-port tube technology, applied in the direction of solid materials, liquid materials, transportation and packaging, etc., can solve the problems of increasing use costs, delaying rescue time for patients, wasting working hours, etc., and achieve saving use costs, saving rescue time, connecting The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

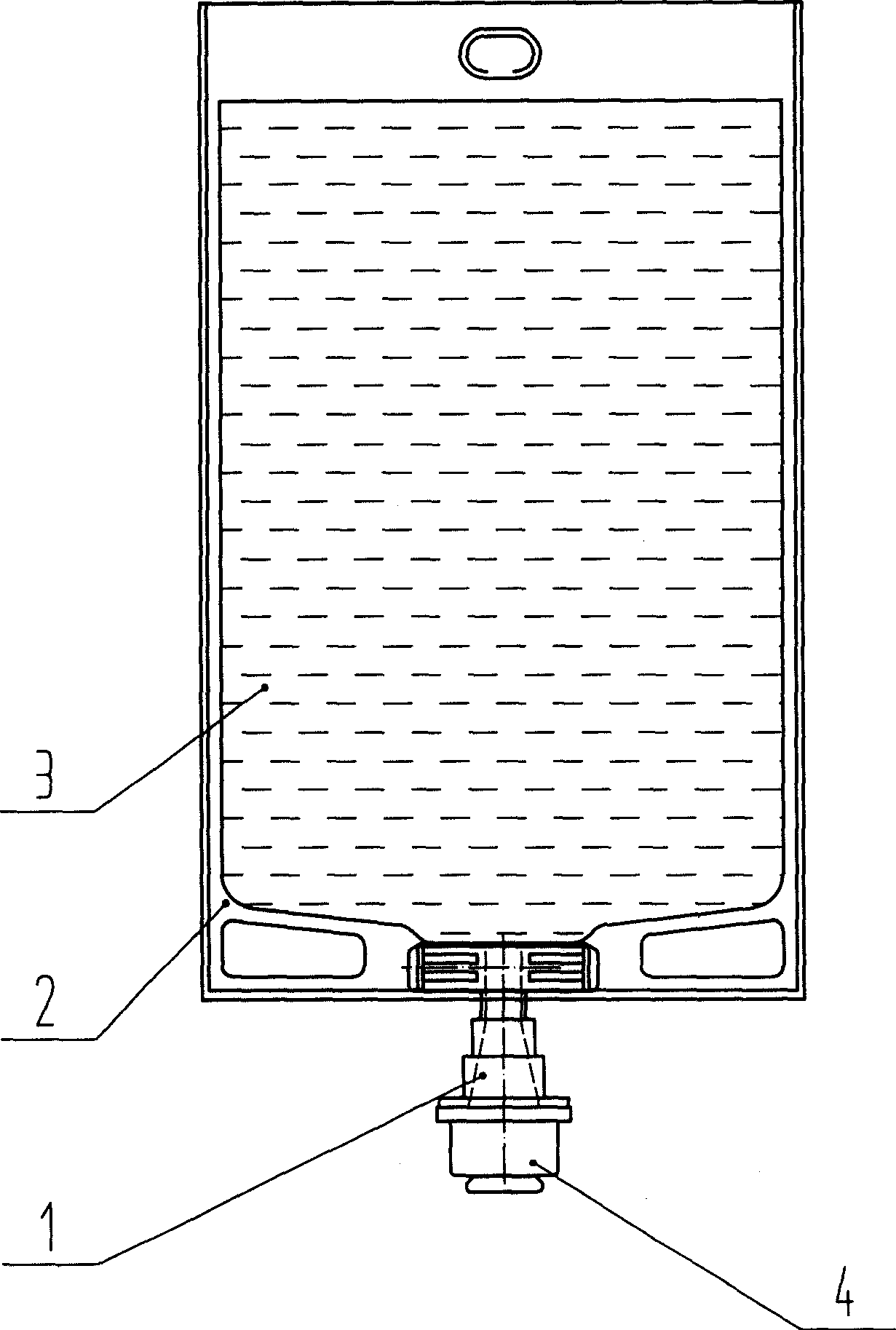

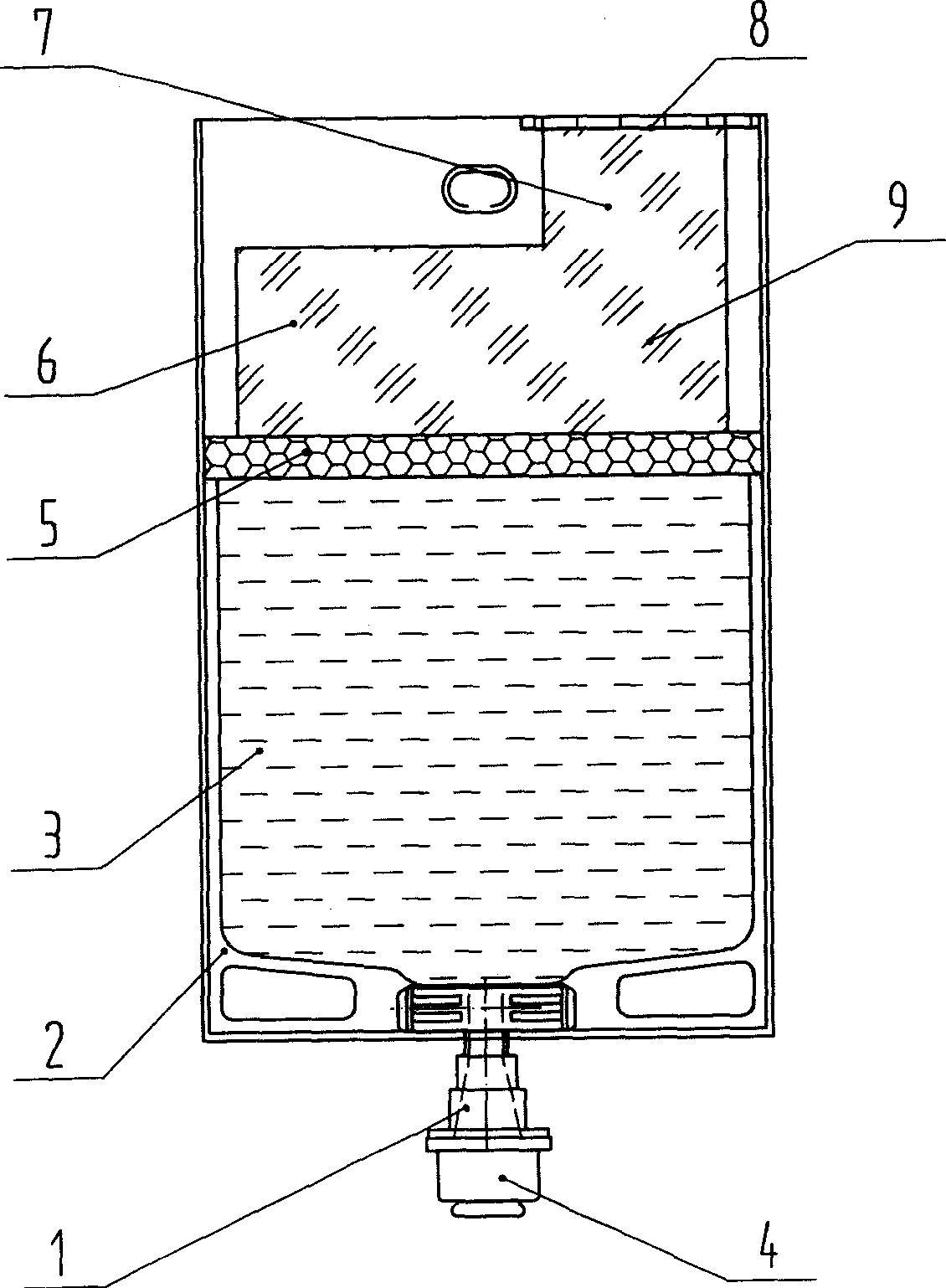

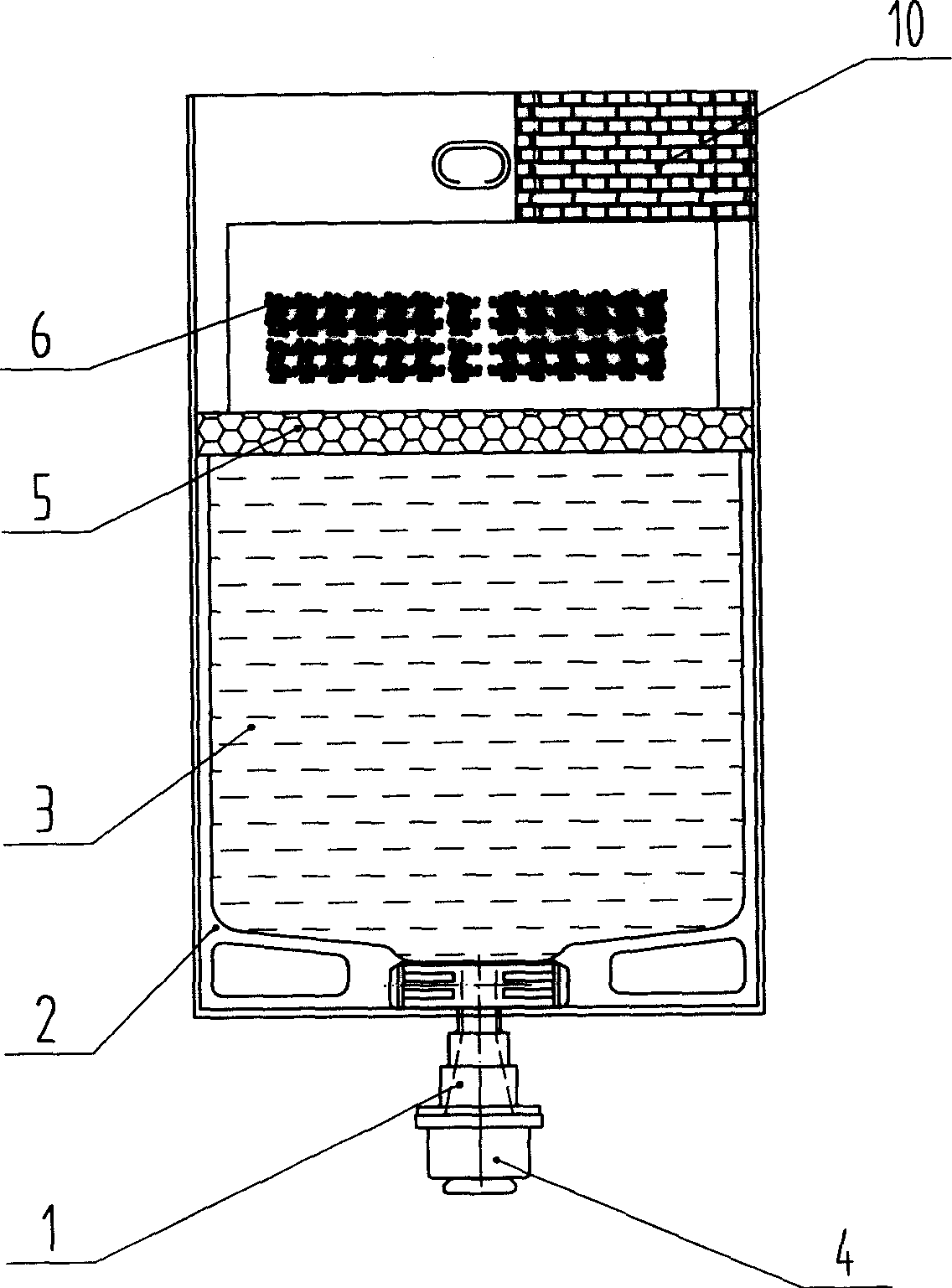

[0083] Such as figure 1 As shown, the non-PVC film soft bag with single-mouth tube liquid-solid type double chambers produced by the present invention is in the form of a semi-finished product, consisting of a connecting tube 1, a liquid medicine chamber 3, a solid medicine chamber 6, a medicine filling port 7, and a combination cover 4. The connection tube 1 is installed at the lower end of the bag body, and the periphery of the bag body is sealed with a high-strength weld seam 2, and a weak weld seam 5 is processed between the liquid medicine chamber 3 and the solid medicine chamber 6, which can completely isolate the two chambers and avoid two medicines Confused with each other before use, the processing of the weak welding seam 5 must ensure that the two drug chambers are both strictly isolated and easy to tear when mixed. In the solid drug chamber 6, it is filled with clean air (or nitrogen) 9, and the inflation is mainly to ensure that the two layers of film in this cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com