Machining method of belt rim

A processing method and pulley technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of unsatisfactory processing efficiency, inability to learn from processing, and lack of flexibility in selecting blanks, and achieve improved processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

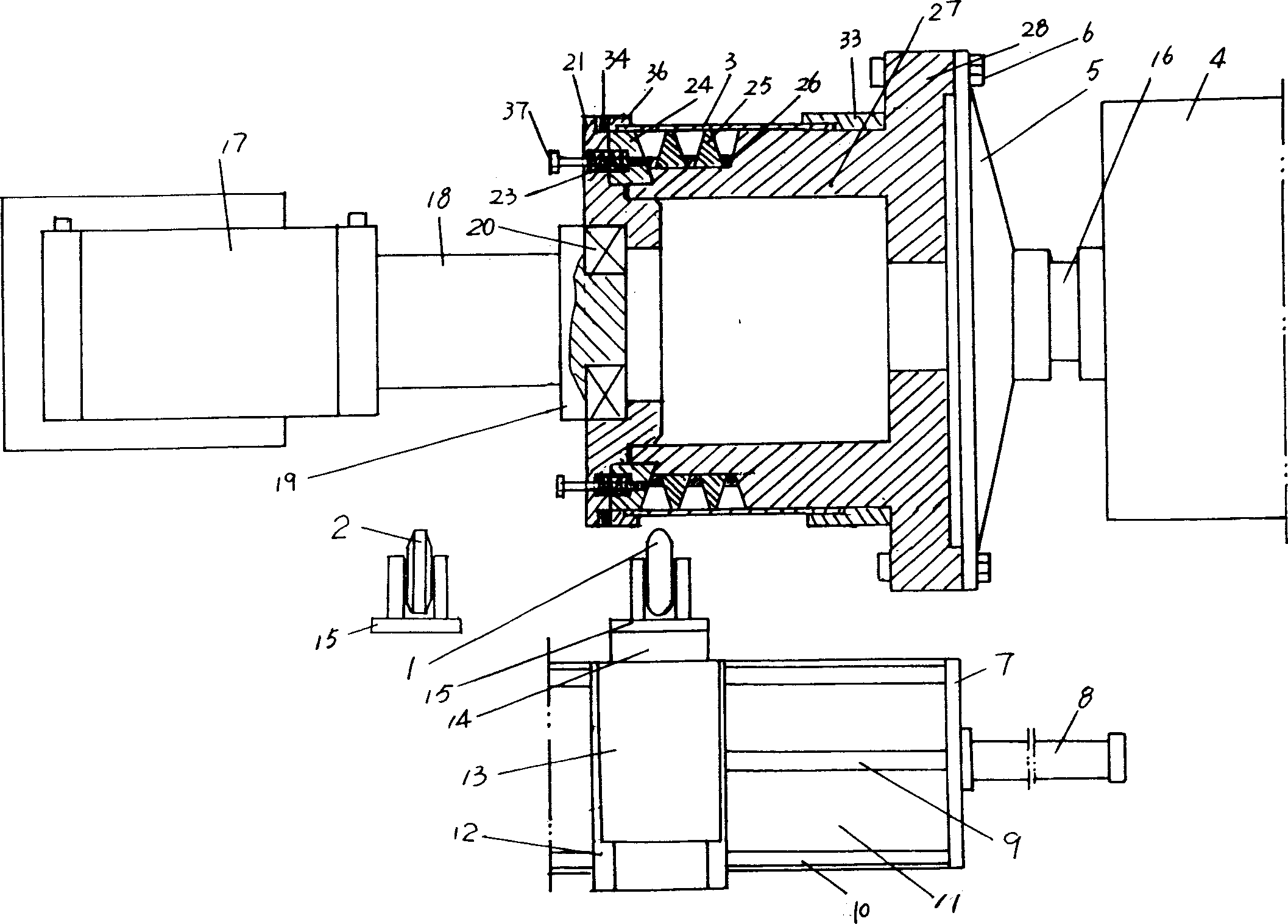

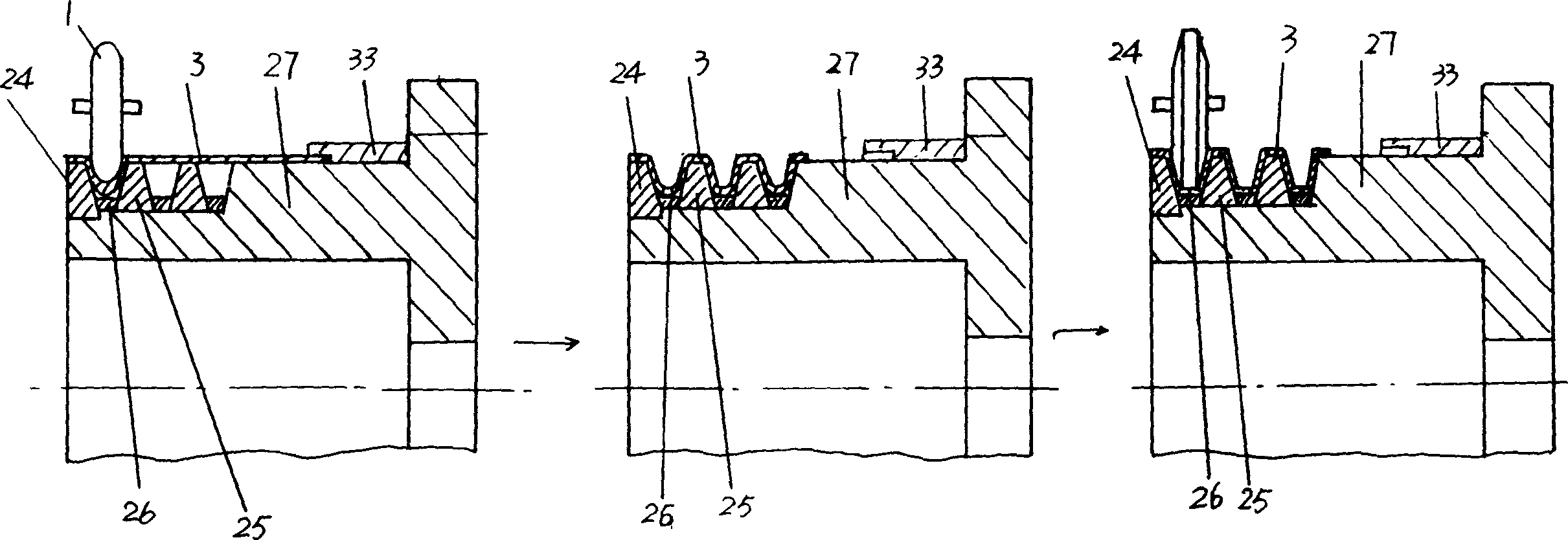

[0031] a) According to the specification requirements of the pulley as the rotating part required by the rotating part such as the axial flow fan or the centrifugal fan used in the textile enterprise, equip a Figure 4 The spinning die shown, and equipped with a spinning groove that can meet the requirements, such as by figure 2 The cross-sectional shape shown is trapezoidal wheel 1 and a same by figure 2 The profile shape shown is trapezoidal forming roller 2;

[0032] b) According to the required diameter, length, wall thickness, material and other requirements of the pulley ring, calculate and grasp the correct size, and then cut a piece such as figure 1 Blank 3 shown;

[0033] c) by figure 2 As shown, the spinning forming die is installed on the general mold plate 5 of the spinning machine 4, and a specific embodiment structure of the spinning forming die described here is composed of Figure 4 Provided, as the lower mold constituting the spinning forming mold, it i...

Embodiment 2

[0041] This embodiment only changes the blanking method of the blank 3 obtained in step b). The flat sheet of thin steel plate with the dimensions shown in the figure is crimped and welded into a mold with the same length as L1 and diameter ΦD as the maximum outer diameter of the core of the spinning die. Figure 6 Blank 3 shown, all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com