Needle ferrichrome-X70 pipeline steel with high crack-arresting toughenss and its production

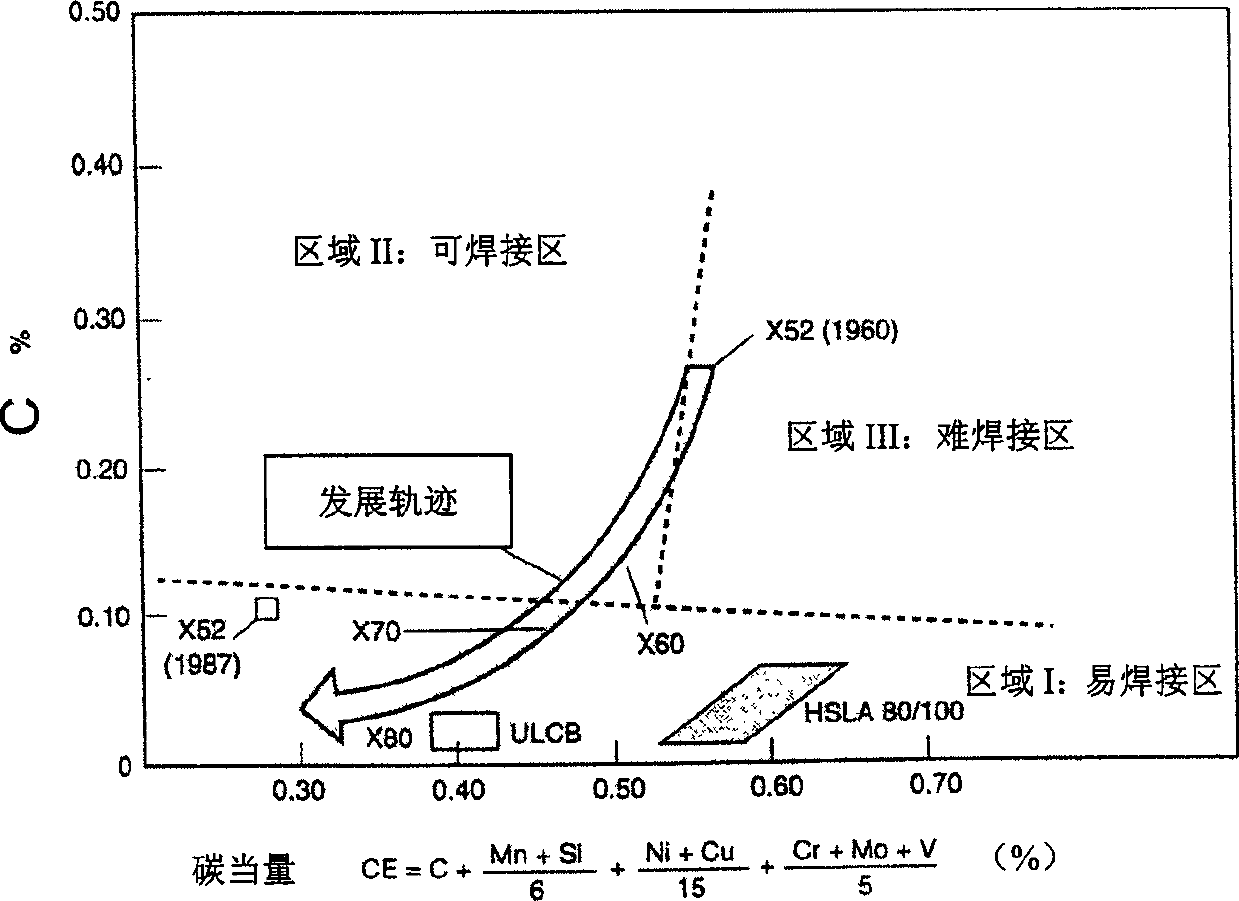

A manufacturing method and pipeline steel technology, applied in the field of pipeline steel and its manufacturing, can solve the problems of high manufacturing difficulty, increased production cost, low Nb content, etc., and achieve high dynamic tear resistance, crack arrest toughness guarantee, high The effect of crack arrest toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0069] 10.3×1550×Cmm X70 pipeline steel hot-rolled coils

[0070] C

mn

Si

S

P

Nb

Ti

V

Mo

Cu

Ni

Alt

N

Ca

0.032

1.46

0.277

0.0015

0.011

0.052

0.021

0.048

0.19

0.21

0.14

0.040

0.0036

0.0034

[0071] Routing:

[0072] LD converter smelting→external refining (RH, LF, Ca wire feeding or Ca powder spraying treatment)→continuous casting→slab finishing→slab reheating→controlled rolling→controlled cooling→coiling

[0073] hot rolling process

[0074] Slab heating temperature: 1191°C;

[0075] End temperature of rough rolling: 960℃;

[0076] Finishing compression ratio: 80%

[0077] Finish rolling termination temperature: 822°C;

[0078] Coiling temperature: 527°C.

[0079] σ 0.5

MPa

σ b

MPa

σ 0.5 / G b

δ 50

%

H V10

CVN-20℃

SA% -15℃ ...

Embodiment B

[0084] Routing:

[0085] LD converter smelting→external refining (RH, LF, Ca treatment)→continuous casting→slab finishing→slab reheating→controlled rolling→controlled cooling→coiling

[0086] hot rolling process

[0087] Slab heating temperature: 1201°C;

[0088] End temperature of rough rolling: 970℃

[0089] Finishing compression ratio: 73%

[0090] Finish rolling termination temperature: 793°C;

[0091] Coiling temperature: 537°C.

[0092] σ 0.5

MPa

σ b

MPa

σ 0.5 / σ b

δ 50 %

H V10

CVN-20℃

SA% -15℃ DWTT

EJ

SA%

530

649

0.82

45

220

334

100

100

[0093] (Note: Both tension and impact are in the direction of 30°, and the size of the CVN impact sample is 10×10×55mm; the transverse cold bending is intact)

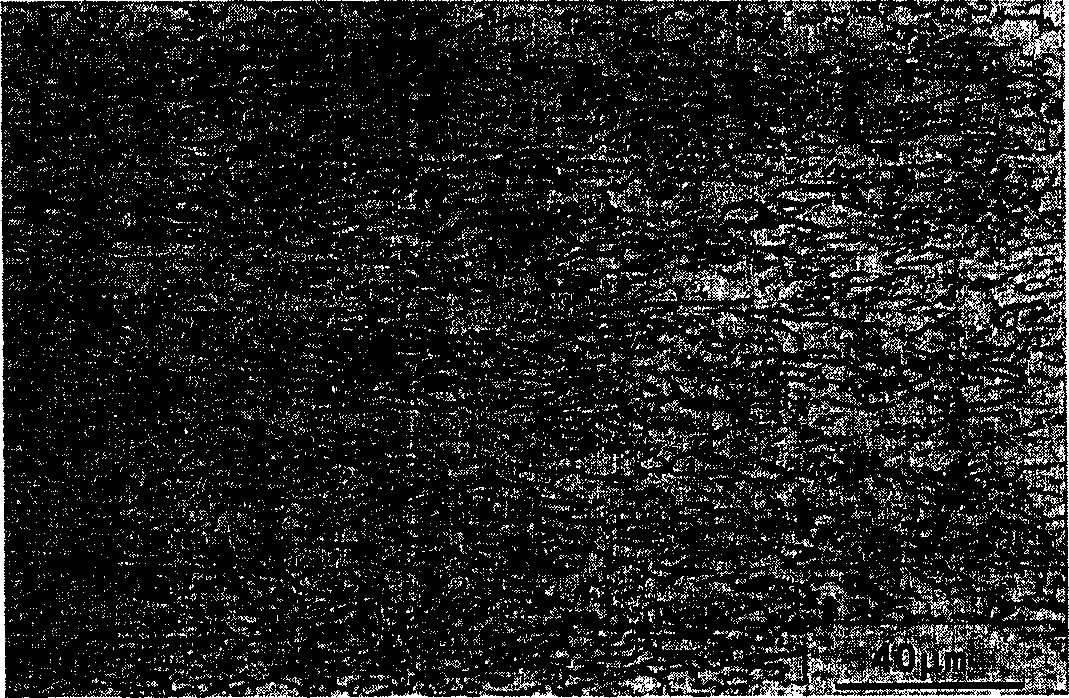

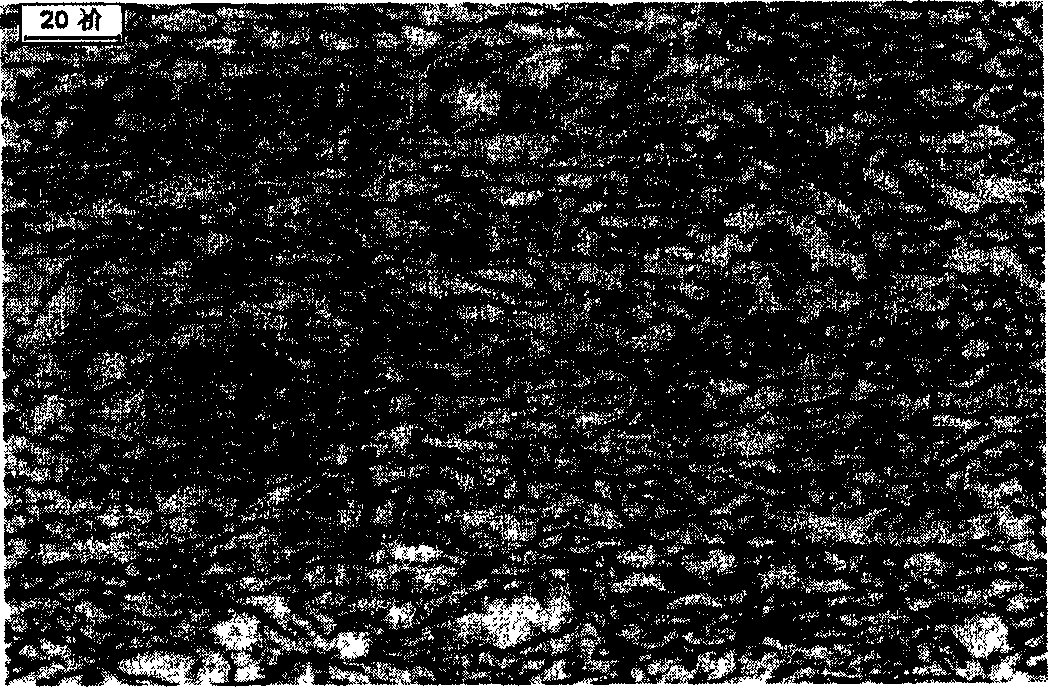

[0094] The schematic diagram of its acicular ferrite metallographic structure is shown in Figure ...

Embodiment C

[0096] 14.6×1550×Cmm X70 pipeline steel hot-rolled coils

[0097] Routing

[0098] LD converter smelting→external refining (RH, LF, Ca treatment)→continuous casting→slab finishing→slab reheating→controlled rolling→controlled cooling→coiling

[0099] Other embodiment composition see table 2:

[0100] implement

[0101] Other embodiment hot rolling process parameters are shown in Table 3:

[0102]

[0103] The properties of the X70 pipeline steel coils corresponding to the composition and hot rolling process in the above table are shown in Table 4.

[0104]

[0105] The acicular ferritic X70 pipeline steel of the present invention will be applied in my country's "West-to-East Gas Transmission" gas transmission pipeline project and the subsequent Shaanxi-Beijing Second Line gas transmission pipeline project, Hening gas transmission pipeline project, etc. With the construction of gas transmission pipelines in my country and the world, the invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com