Honeycomb composite plate core board

A composite core and honeycomb technology, applied in beehives, beekeeping, applications, etc., can solve the problems of high flatness requirements, low mechanical strength, high manufacturing cost, etc., to improve mechanical strength, improve production efficiency, and manufacturing methods flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

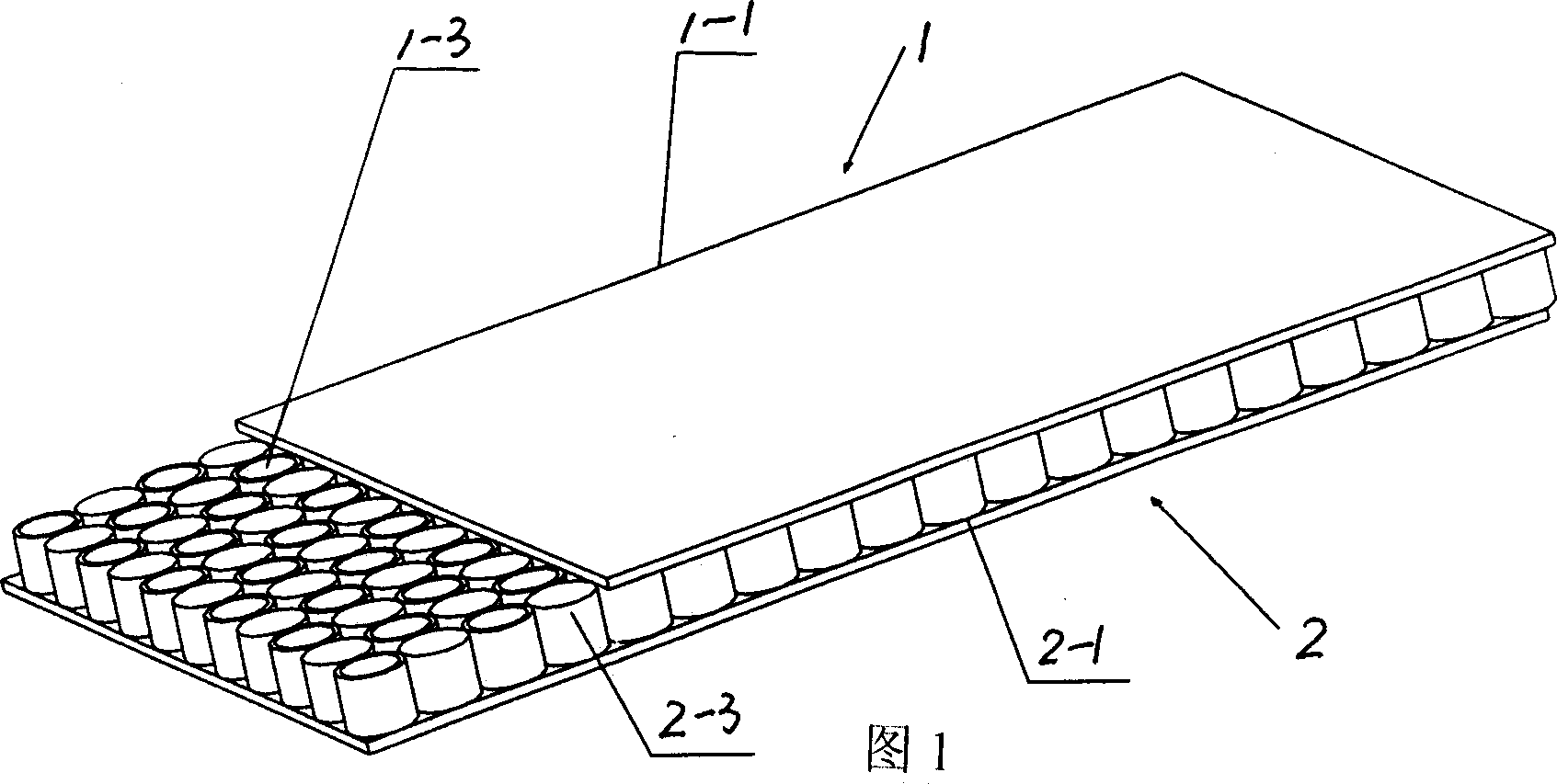

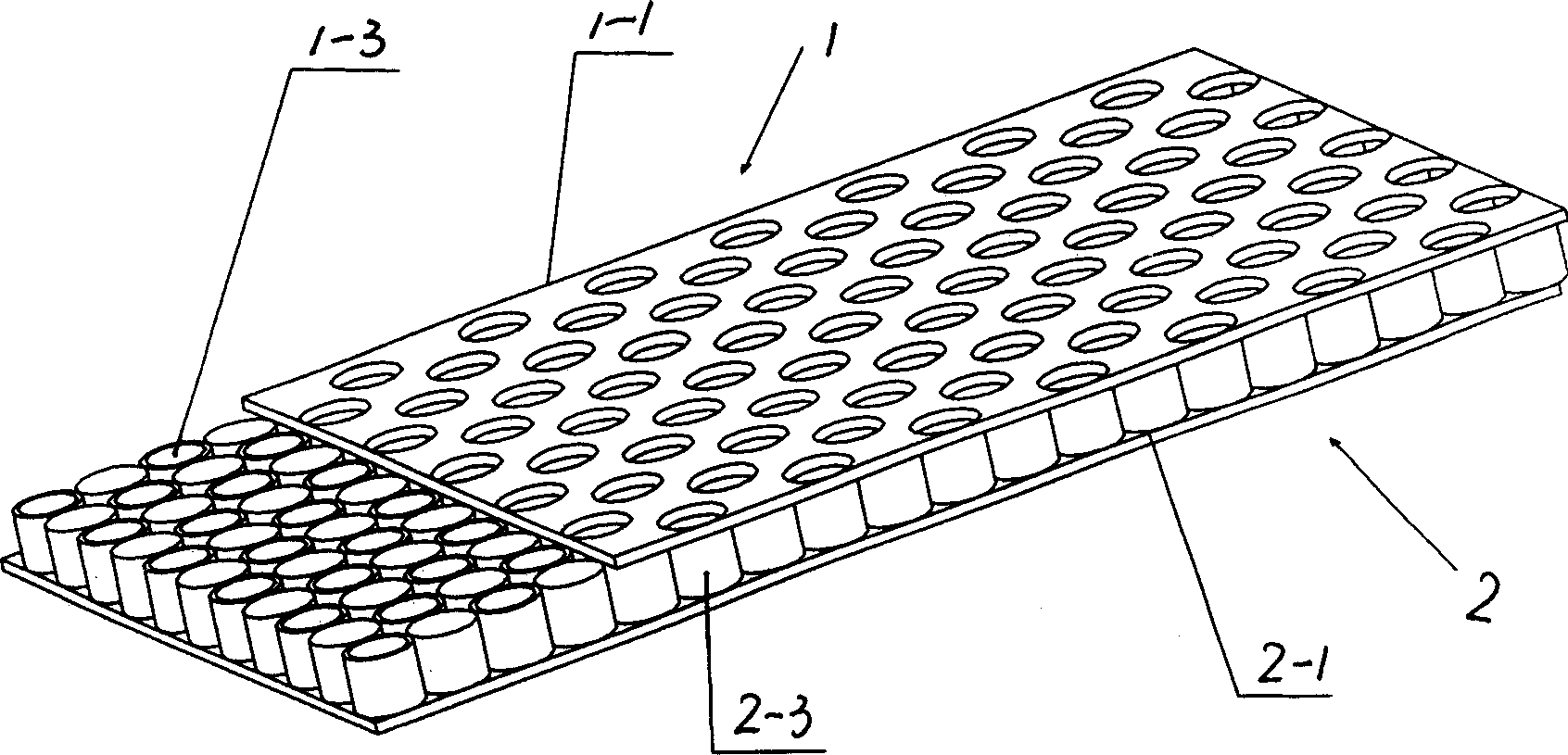

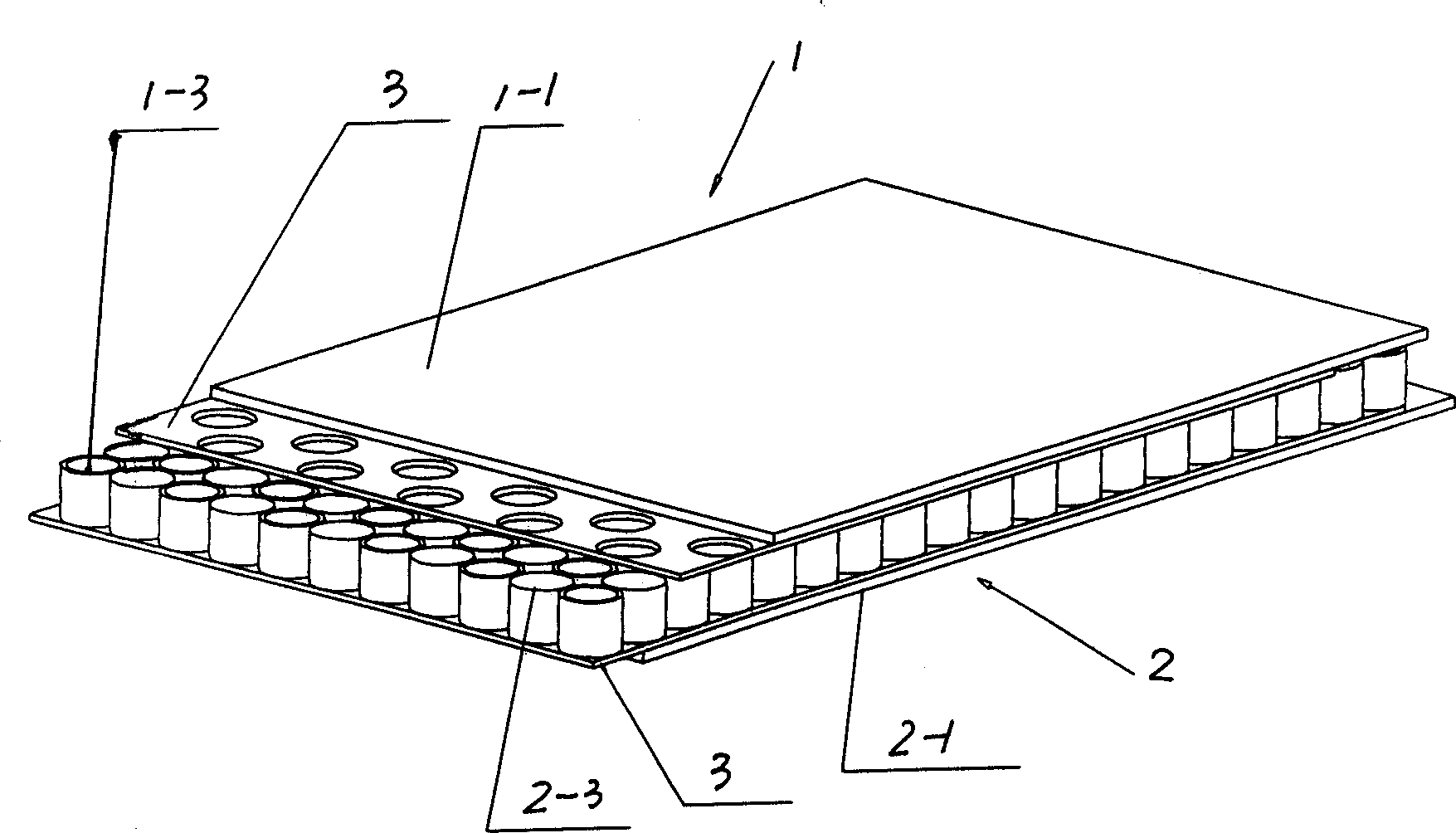

[0025] See the honeycomb composite core plate shown in Figures 1-4, including a cover plate 1-1 and a mother plate 1 composed of regularly arranged columns or pyramidal columns arranged on the cover plate 1-1. Two motherboards 1, 2 are stacked together, the adjacent sides of the cylinders or cones on the two cover plates 1-1, 2-1 are inserted into each other, and the two cover plates 1-1, 2-1 The surface on one side of the column or cone is respectively connected to the top of the opposite column or cone to form a honeycomb body with cover plates on both sides.

[0026] See Figure 5 As shown, the columns regularly arranged on one side of the cover plate 1-1 are cylinders 1-3. When the two motherboards 1 and 2 are stacked together, as shown in Figure 1, the cover bodies 1-1, 2-1 The sides of the cylinders 1-3 and 2-3 on the top are plugged in with each other, and the surfaces of the two cover plates 1-1 and 2-1 on one side of the cylinders 1-3 and 2-3 are respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com