Method and device for igniting detonator

A detonator and chip technology, used in fuzes, blasting tubes, weapon accessories, etc., can solve the problems of anti-static, anti-stray current and poor electromagnetic radiation resistance, and achieve high anti-electromagnetic radiation ability, strong environmental adaptability, and anti-miscellaneous radiation. The effect of dissipating current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

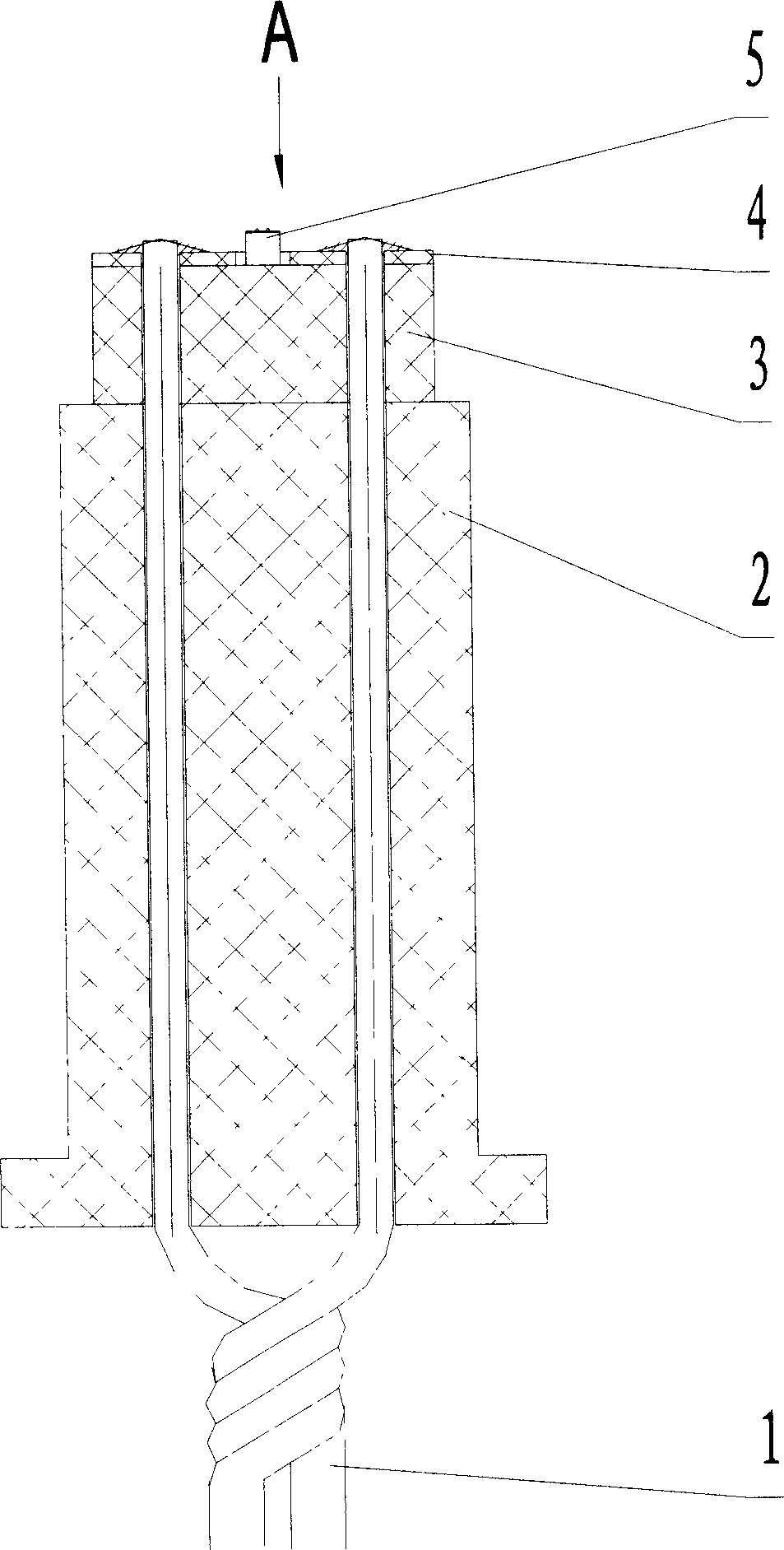

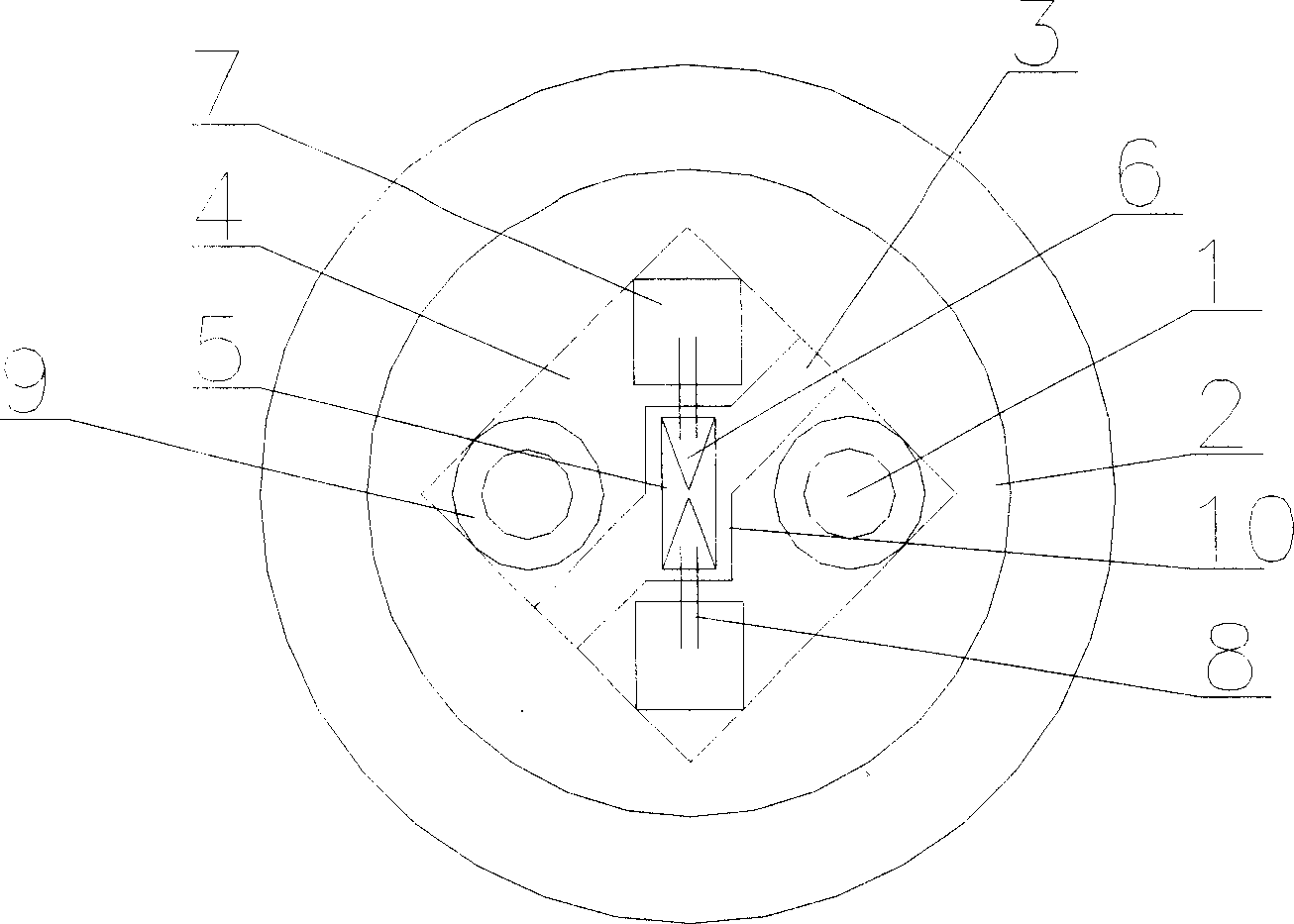

[0014] Embodiment of the present invention: when making the ignition and detonation device of electric detonator, adopt the semiconductor chip 5 made of polysilicon material sold on the market as the ignition detonation material of electric detonator, and use the detonation power source of the original electric detonator as the ignition source of this semiconductor chip Power supply, so that the current pulse of the power supply can act on the semiconductor material, so that when the electric detonator is detonated, the current pulse flows through the semiconductor material to heat it, and after the semiconductor material is vaporized, an explosion is generated to form a high temperature and high pressure plasma impact body , the heat energy generated by the plasma and the ejected plasma act on the detonating particles in the detonator to ignite the explosive in the detonator, thereby detonating the detonator.

[0015] When specifically manufacturing the ignition and detonation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com