Hydraulic reciprocating pump

A reciprocating pump and hydraulic technology, applied in the direction of pumps, piston pumps, liquid displacement machinery, etc., can solve the problems of high cost, complex structure of reciprocating pumps, and restrictions on popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

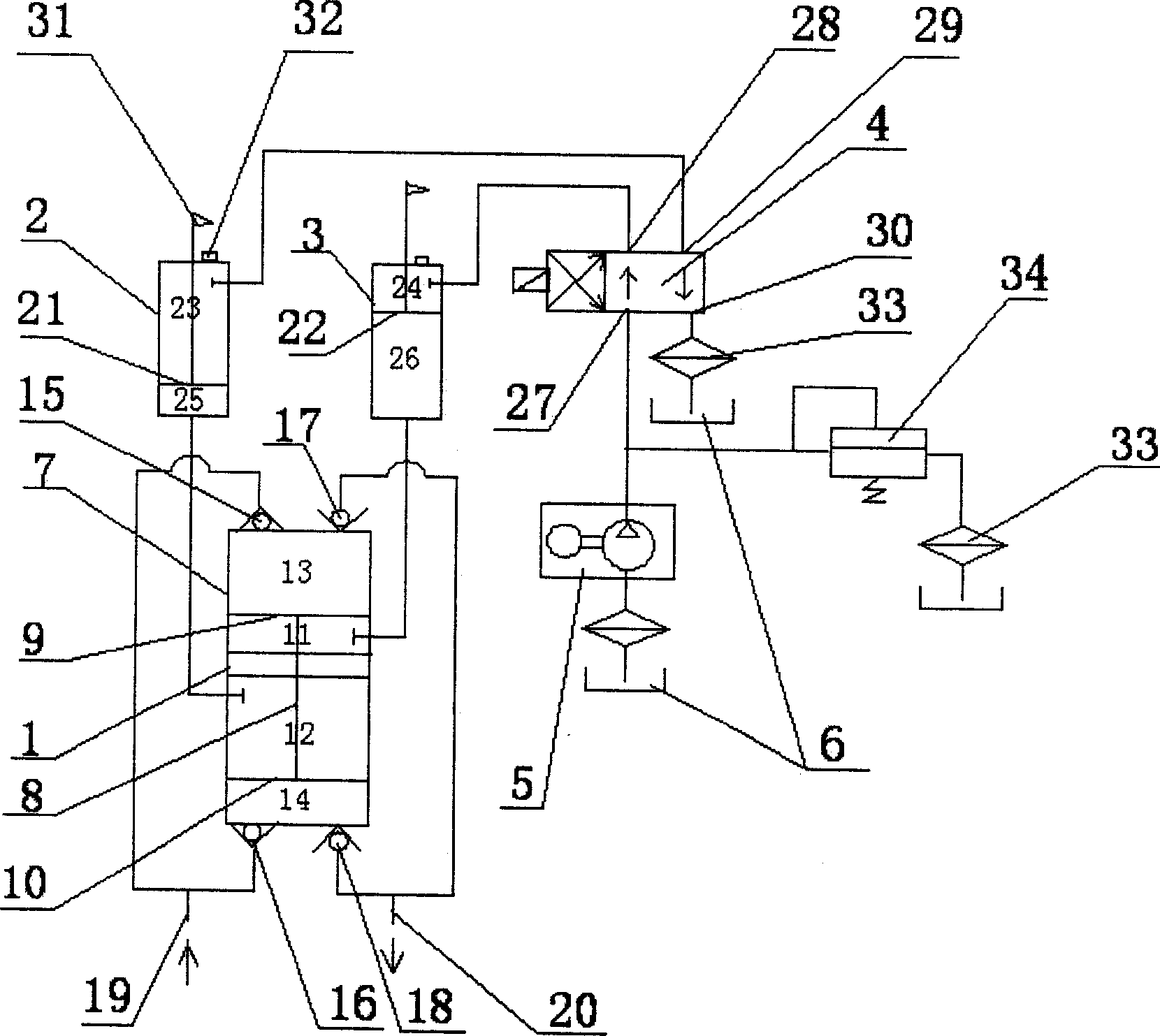

[0015] Such as figure 1 As shown, the hydraulic reciprocating pump of the present invention includes a reciprocating pump 1, two power cylinders 2, 3, a reversing valve 4, a pump motor unit 5 and an oil tank 6 with hydraulic oil; wherein:

[0016] The reciprocating pump 1 includes a pump body 7 with two connected chambers and a piston assembly. The piston assembly is composed of a piston rod 8 and two pistons 9, 10 installed at both ends of the piston rod 8. The two pistons 9, 10 are respectively Set in the two chambers of the pump body 7, and divide the chambers into hydraulic chambers 11, 12 and working chambers 13, 14, the working chambers 13, 14 are respectively connected with liquid inlet check valves 15, 16 and liquid outlet One-way valves 17, 18, wherein the liquid inlet one-way valves 15, 16 are connected to the liquid inlet pipe 19, and the liquid outlet one-way valves 17, 18 are connected to the liquid outlet pipe 20, and the reciprocating pump 1 can be a vertical or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com