Power frequency resonance type induction electric boiler

A technology of induction electricity and frequency resonance, which is applied in the field of industrial frequency resonance induction electric boilers, can solve the problems of low calorific value, large active power loss, increased energy-consuming equipment and manufacturing costs, etc., to achieve reduced manufacturing costs, small active power losses, The effect of saving additional loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

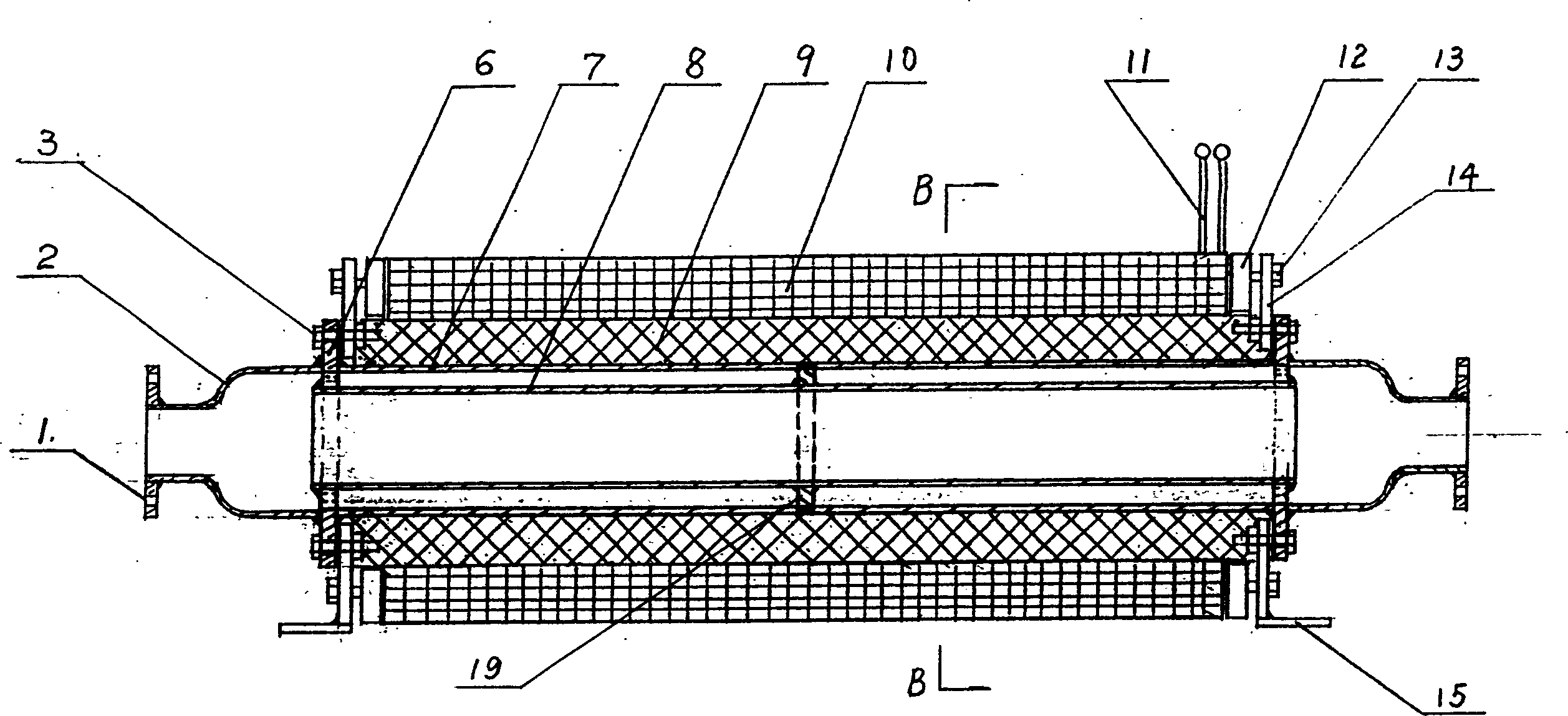

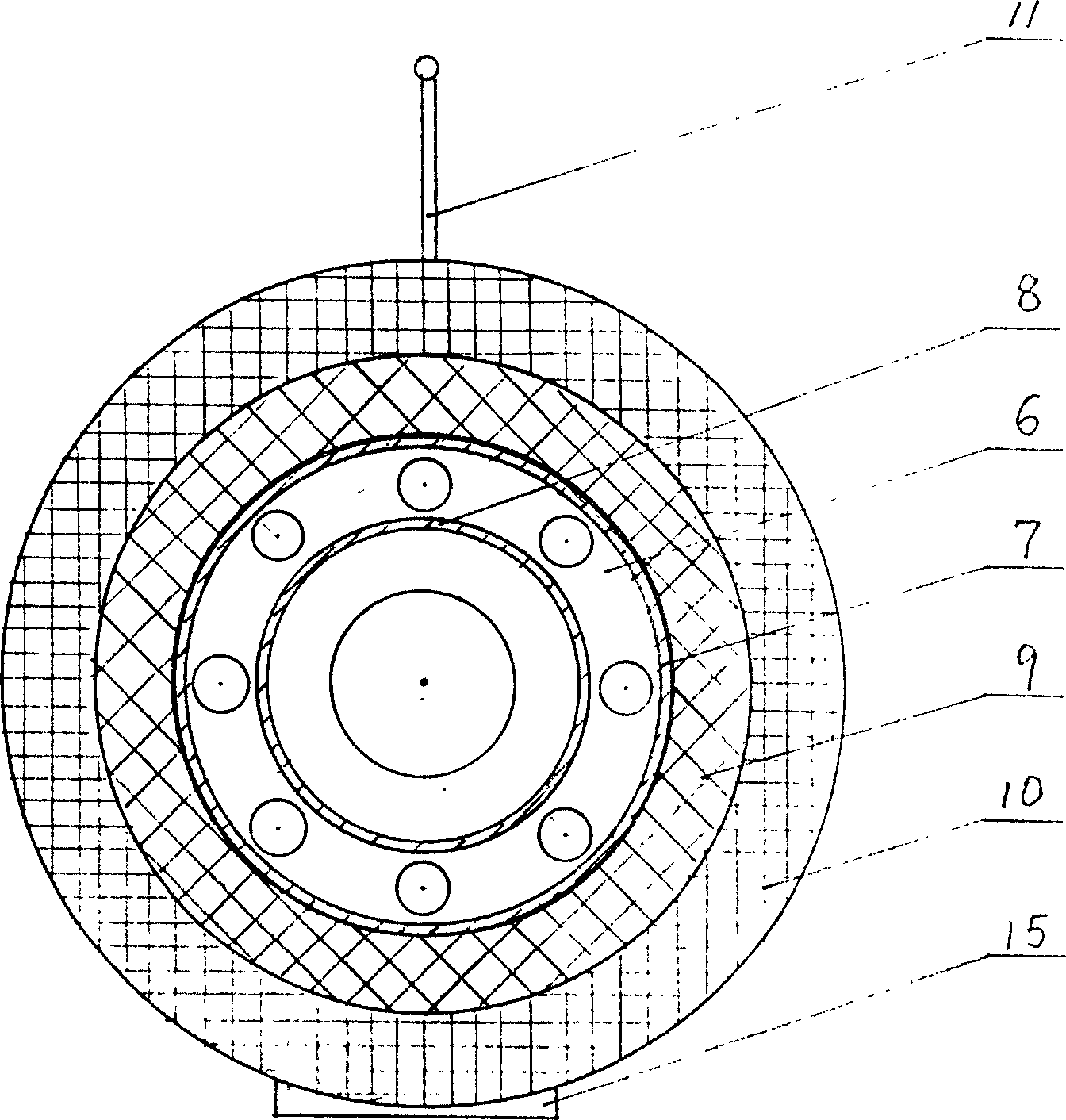

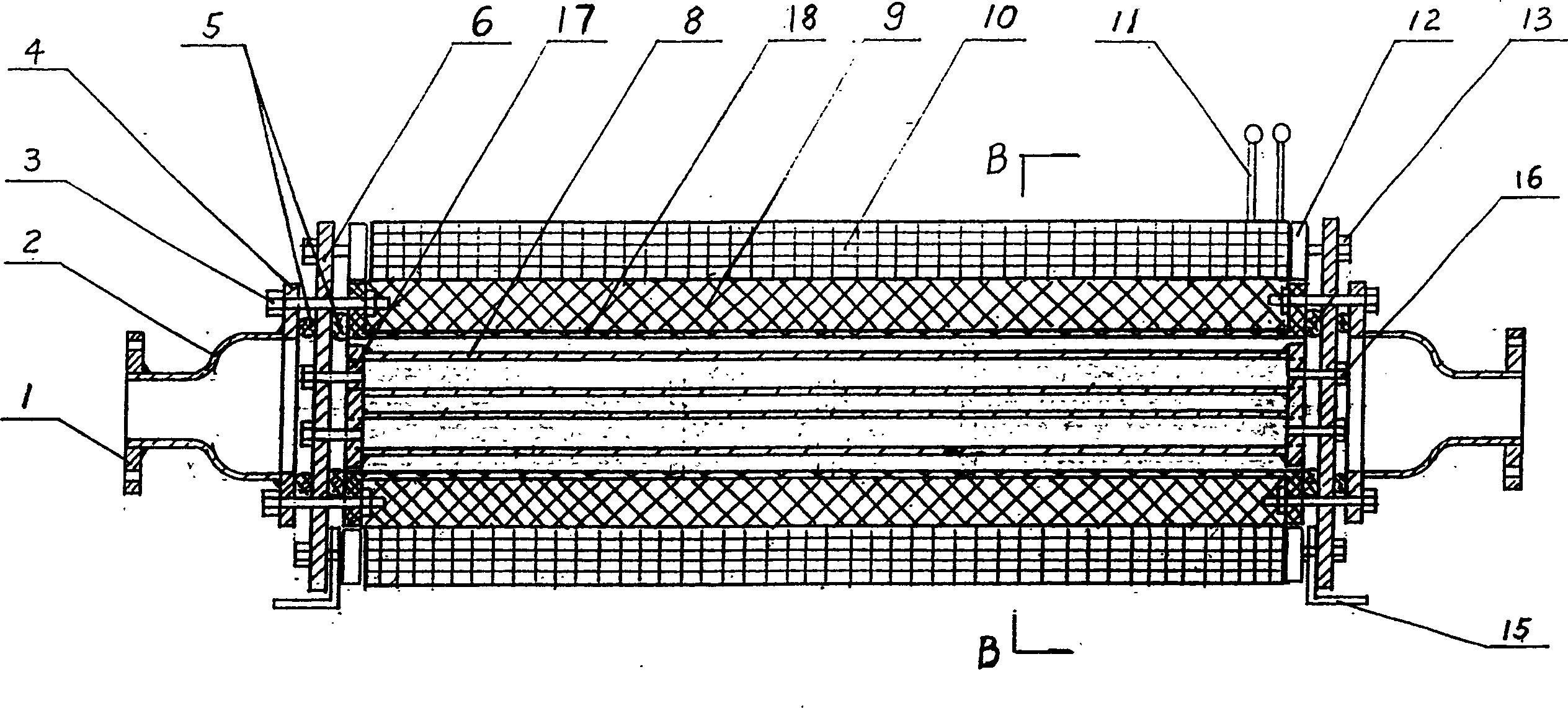

[0062] figure 1 with figure 2 Shown is an induction heating pipe 30 composed of a heating steel pipe 8 . The heating steel pipe 8 is placed in parallel in the non-magnetic stainless steel water pipe 7 . There is a gap for circulating water between the outer diameter of the heating steel pipe 8 and the inner diameter of the non-magnetic stainless steel water pipe 7 . On the porous sealing plate 6 with flange, there are a plurality of water holes at the water gap between the heating steel pipe 8 and the non-magnetic stainless steel water pipe 7 . The porous fixed plate 19 is welded on the middle part of the heating steel pipe 8 earlier, and then welded on the middle part of the non-magnetic stainless steel water pipeline 7. The body pipeline of the heating steel pipe 8 is welded into one body after correspondingly penetrating through the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com