Combined aluminium pipe rock radiator

A radiator and tube belt type technology, applied in the direction of heat exchanger type, indirect heat exchanger, fixed pipe assembly, etc., can solve the problems of easy blockage of heat dissipation belt windows, cost reduction, and difficulty in cleaning, etc., and achieve easy vehicle assembly Arrangement, cost reduction, and good heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

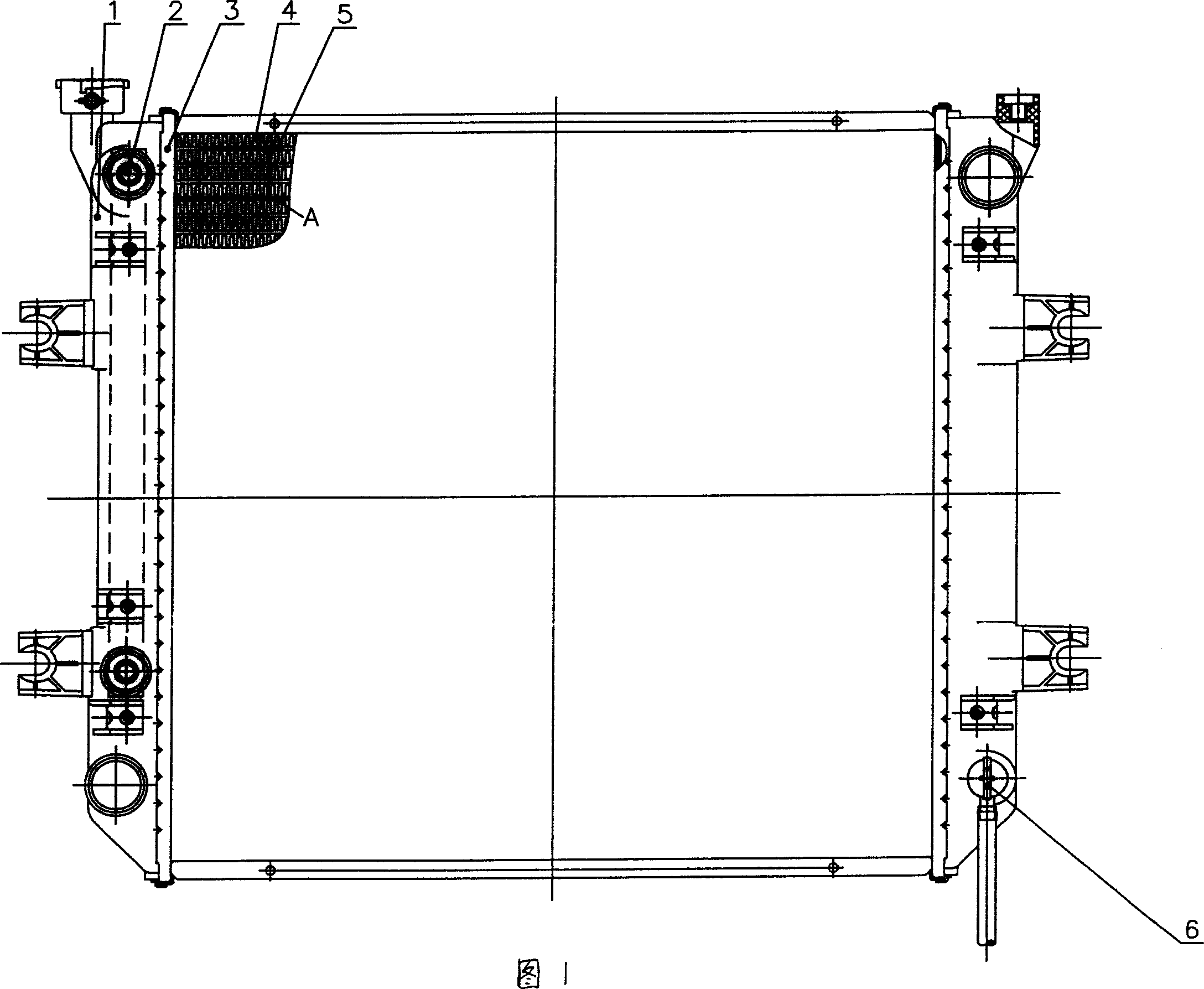

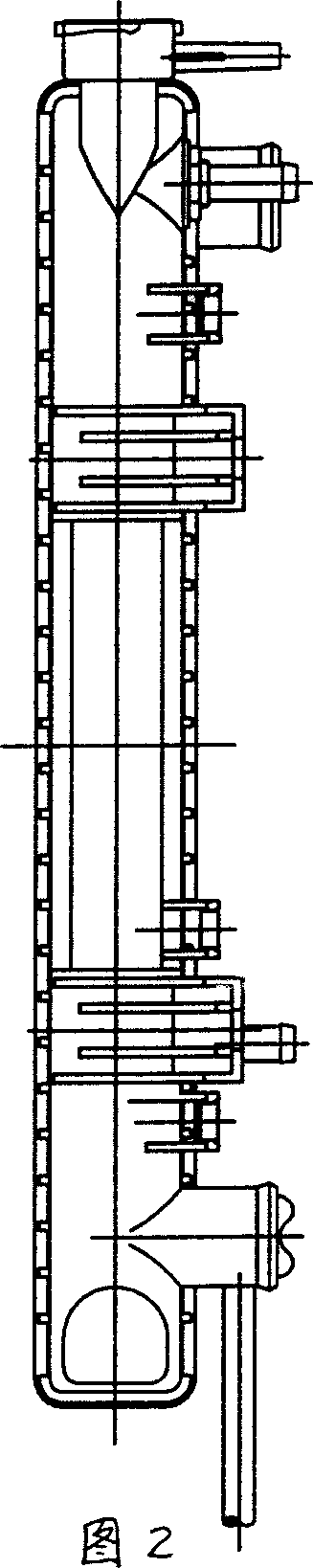

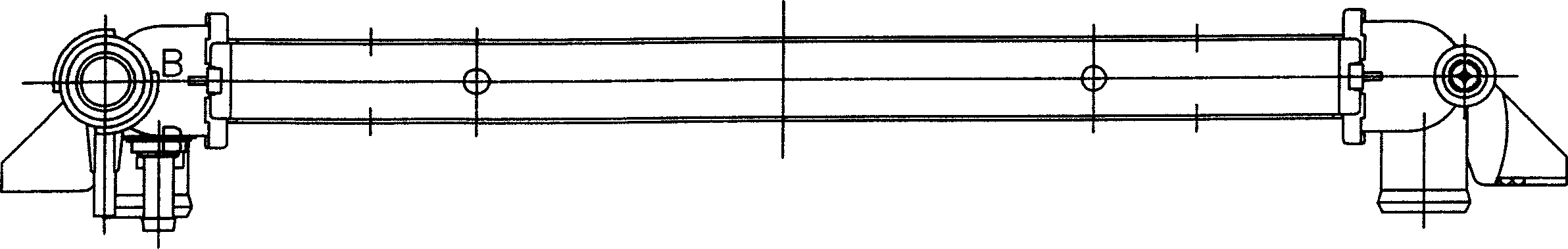

[0015] As shown in the figure, the left and right sides of the combined aluminum tube-and-belt radiator in this embodiment are water chambers 1, and the water chamber is made of injection molded parts, which greatly reduces the weight of the radiator and reduces the phenomenon of radiator vibration and cracking. The oil-water combination structure is adopted, and the oil cooler 2 is arranged in the water chamber to cool the torque converter oil while cooling the engine cooling water. The inner sides of the left and right water chambers are respectively provided with vertical main boards 3, and heat dissipation belts 4 and heat dissipation pipes 5 are arranged between the two main boards. Between two adjacent heat dissipation pipes 5, each heat dissipation strip is composed of a plurality of diamond-shaped units that are repeated continuously, and each unit is diamond-shaped without windows and ribs. Tube 5 is welded. Since each unit has 3 welding points, the welding strength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com