Motor damping device

A shock absorber and motor technology, applied in the direction of electromechanical devices, casings/covers/supports, electrical components, etc., can solve the time-consuming assembly of shock absorbers, the inability to effectively block resonance high-frequency noise, start high-frequency noise, and positioning Poor effect and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Please refer to Figure 2A , which shows a side view of the structure of the motor fixed to the mechanism fixing member configured with the motor damping device according to the first embodiment of the present invention. A general motor 200, such as a projector color wheel motor, has a clamping part 202 for locking on the mechanism fixing part 210, and the mechanism fixing part 210 has the above-mentioned three equidistant two-dimensionally arranged locking holes 212 (for To avoid complicated illustrations, the side view only shows two locking holes 212 ), which are used to lock the clamping part 202 and the mechanism fixing part 210 with screws 214 . The motor damping device 220 is disposed on the mechanism fixing part 210 to reduce the vibration of the motor transmitted from the clamping part 202 directly or via the screw 214 to the mechanism fixing part 210 .

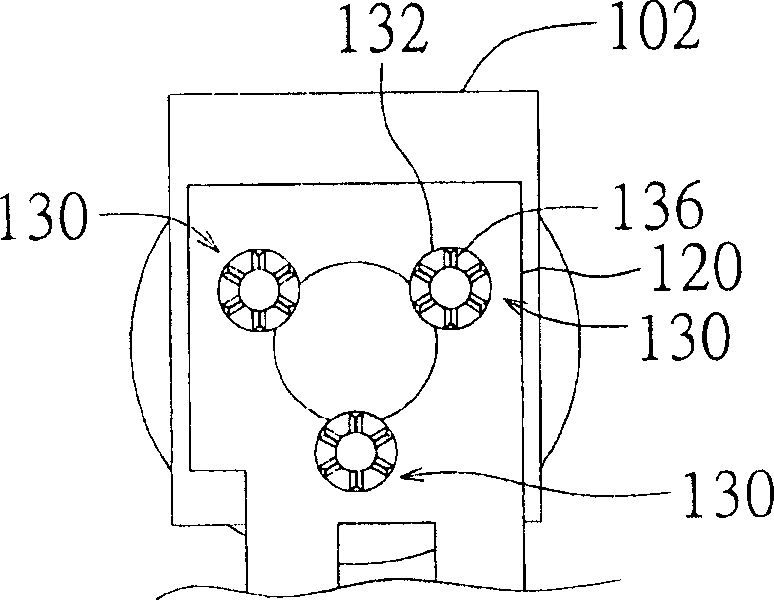

[0023] Please also refer to Figure 2B as well as Figure 2C , respectively plotted Figure 2A Top view...

example 2

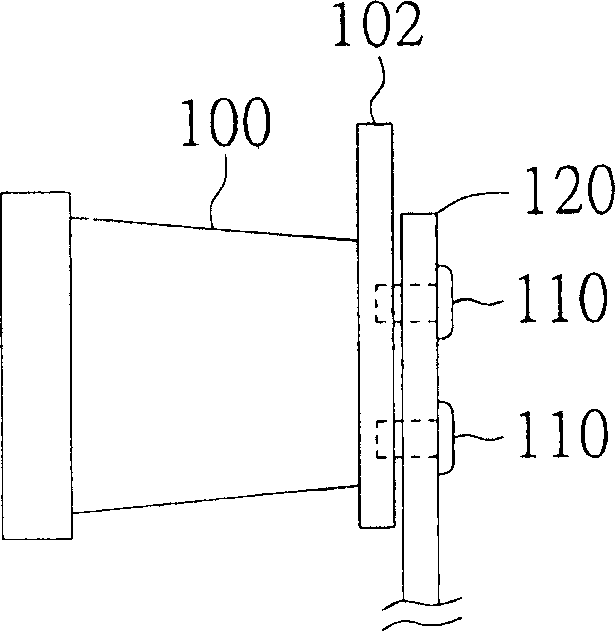

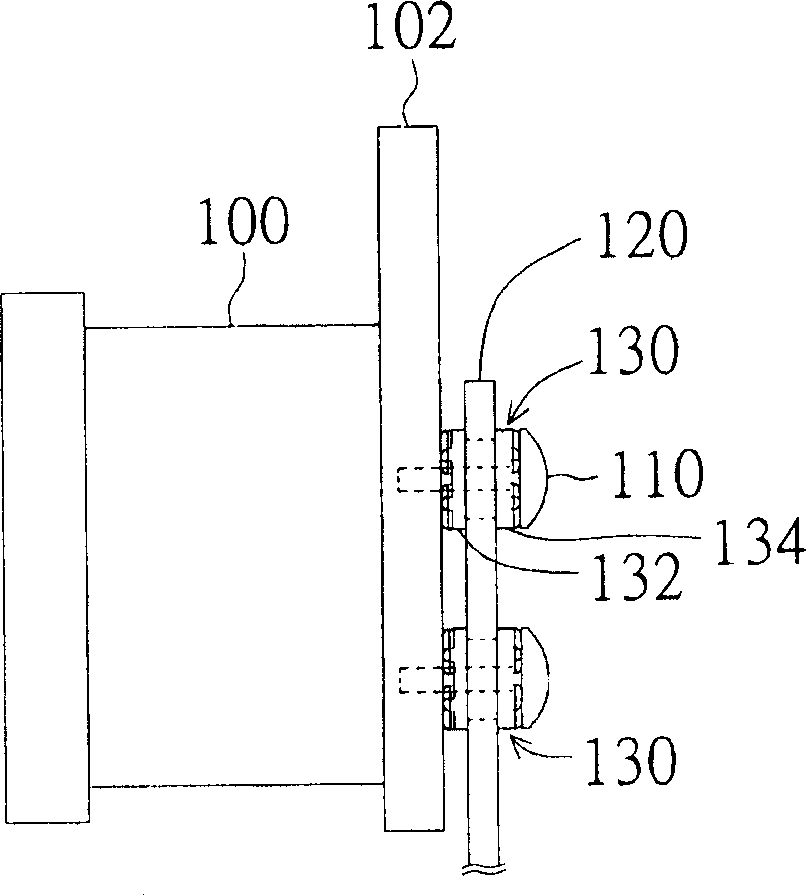

[0027] Please refer to Figure 3A , which shows a side view of the motor fixing structure with the motor damping device according to the second embodiment of the present invention. A general motor 300, such as a projector color wheel motor, has a clamping part 302 for locking on the mechanism fixing part 310, and the mechanism fixing part 310 has the above-mentioned three equidistant two-dimensionally arranged locking holes 312 (for To avoid complicated illustrations, the side view only shows two locking holes 312 ), which are used to lock the clamping part 302 and the mechanism fixing part 310 with screws 314 . The motor damping device 320 is used to reduce the vibration of the motor transmitted to the mechanism fixing part 310 through the clamping part 302 and the screw 314 .

[0028] Please also refer to Figure 3B as well as Figure 3C , respectively plotted Figure 3A A top view and a side view of the middle motor damping device 320 in a deployed state. The motor sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com