Winder and winding method of filament body

A winding device and thread technology, applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., to achieve the effect of avoiding the deterioration of characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

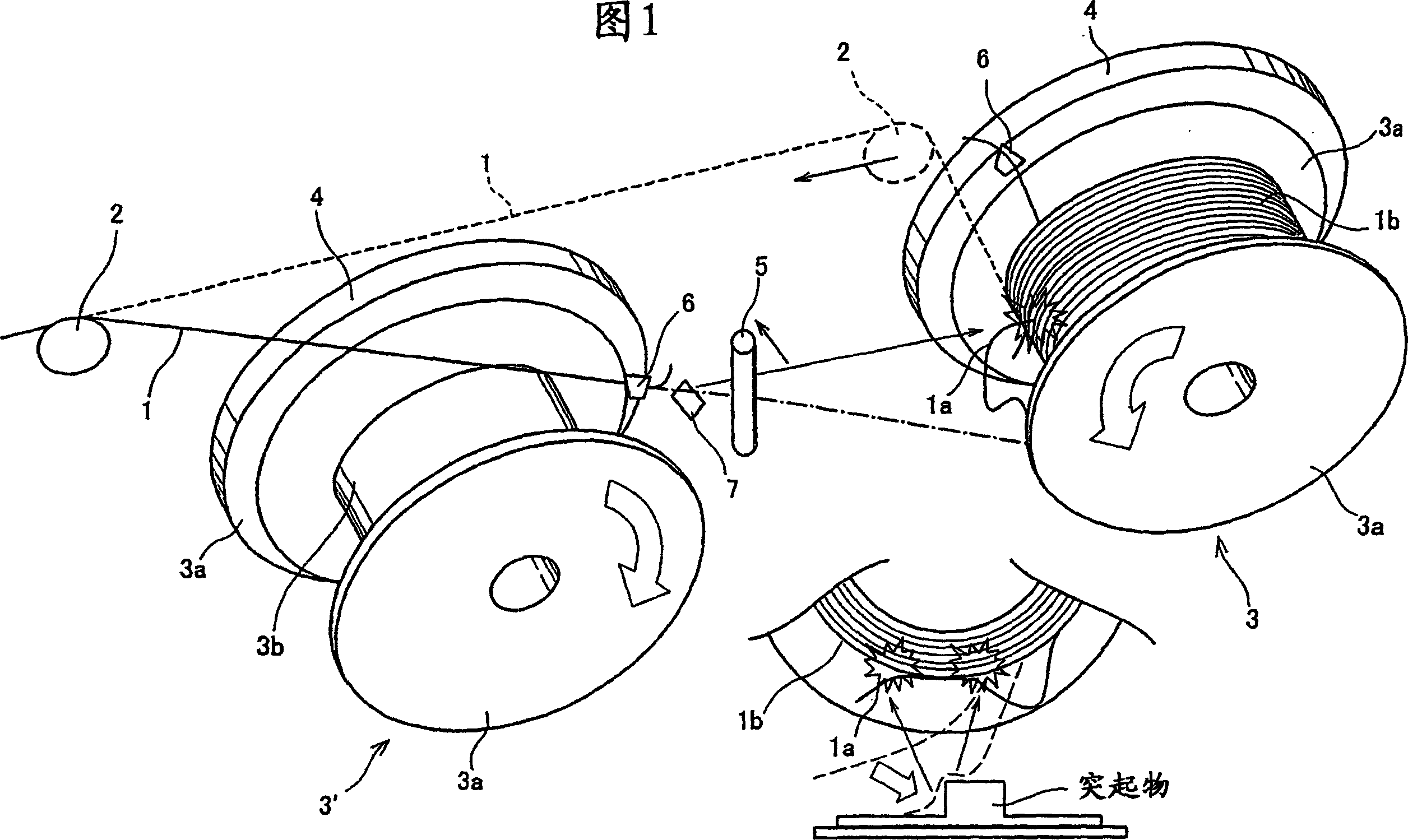

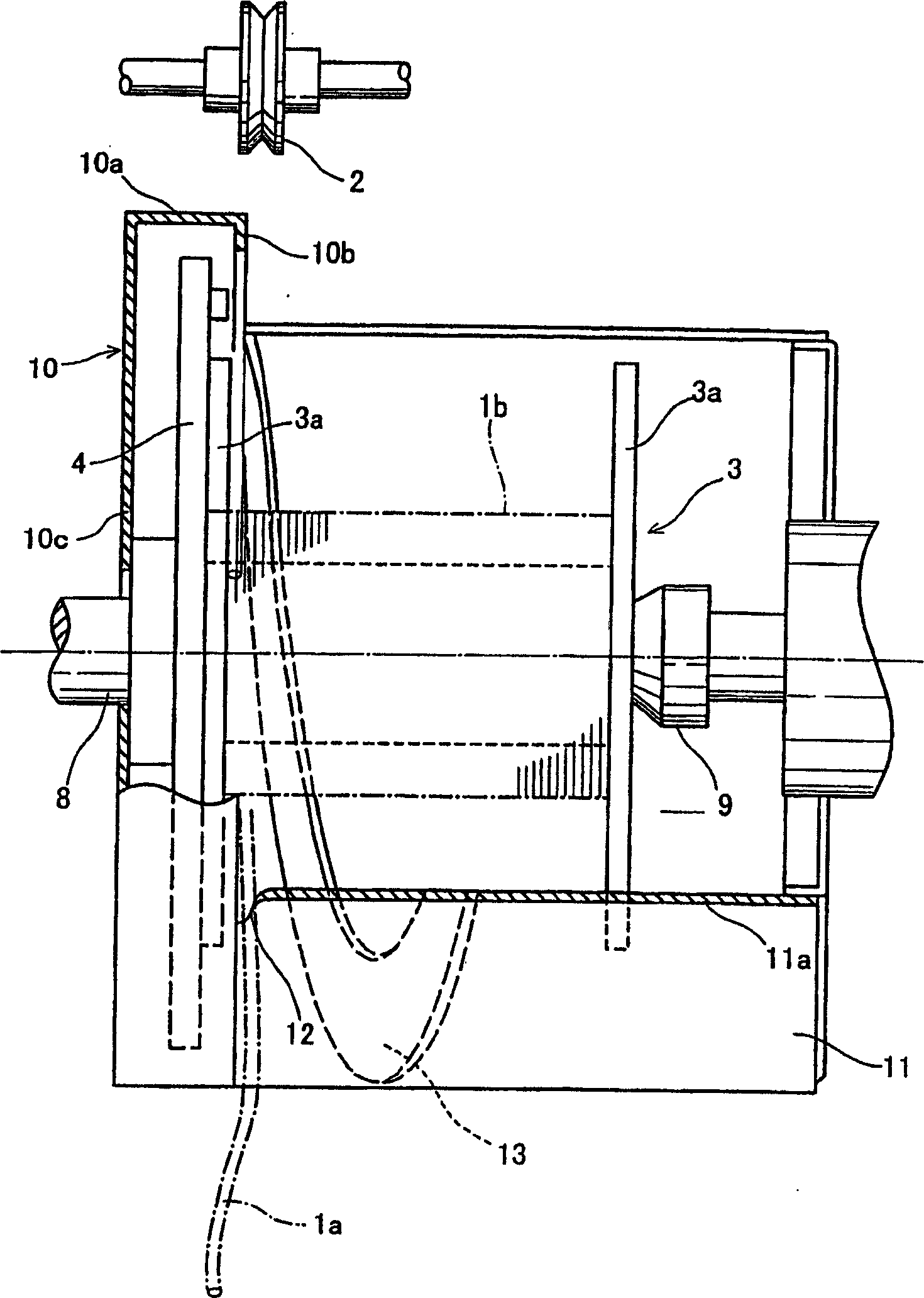

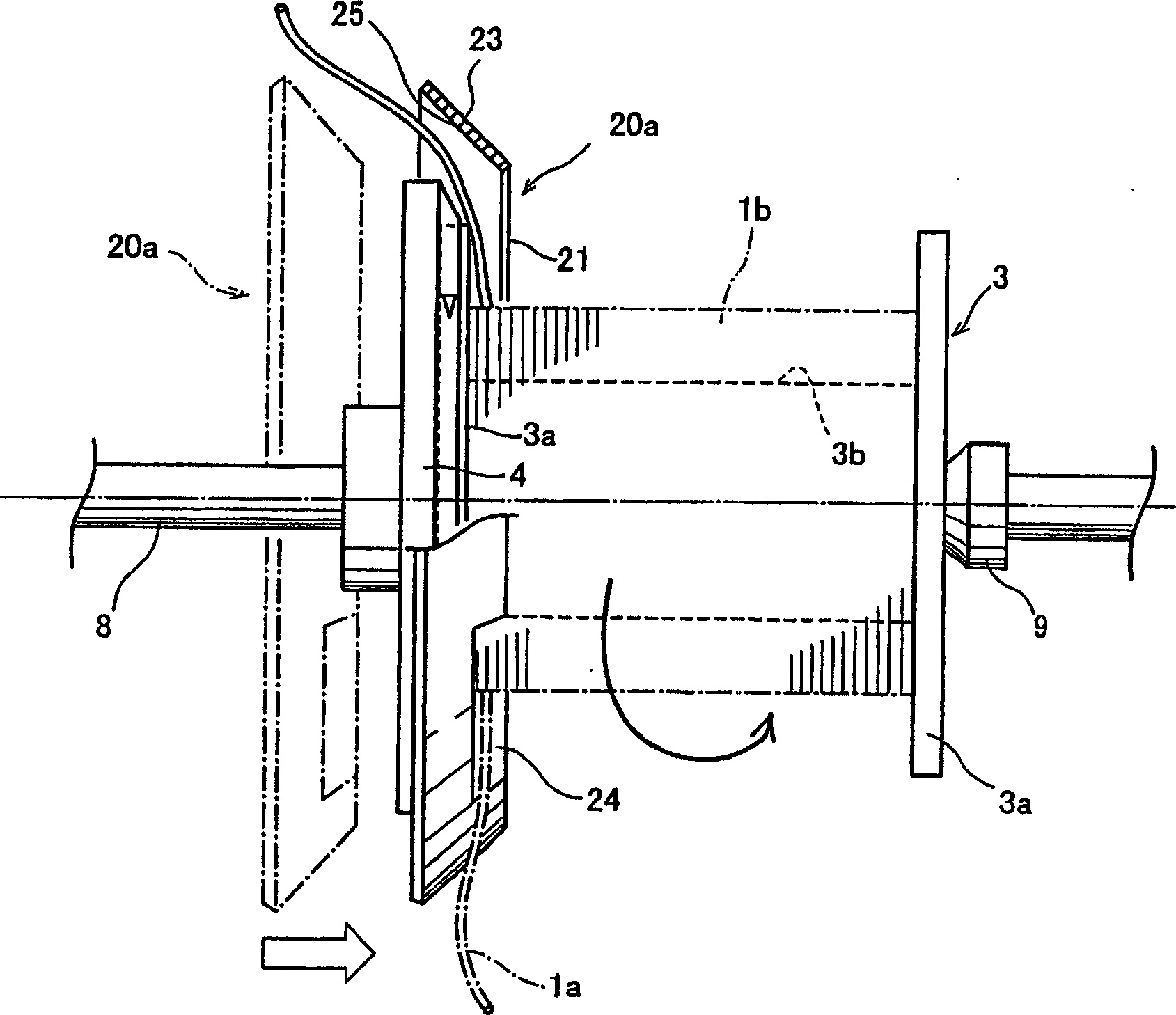

[0027] use image 3 , Figure 4 and Figure 5A ~ Figure 5C Embodiments of the present invention are schematically described. image 3 It is a figure explaining the example of guiding the cut terminal part of the strip to the outside of the winding bobbin, Figure 4 It is an explanatory diagram of an example of the cutting terminal part where the strip is fixed to the fixing part of the ring guide, Figure 5A is a figure showing another example, Figure 5B and Figure 5C It is a diagram illustrating another example of the fixing portion of the annular guide; in the figure, 20a, 20b, 20c, 20d are annular guides, 21 is an opening, 22 is a side wall, 23 is an outer peripheral wall, 24 is a notch, and 25 is a The inner peripheral surface 26 is a fixing part. Other numbers are the same as in Figure 1 and figure 2 is the same as that used in , so its description is omitted.

[0028] Winding device of the present invention, such as image 3 shown, with figure 2 As described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com