Method for building a dam through solidifying red mud rapidly

A rapid solidification and red mud technology, which is applied in the field of dam construction technology of sintered red mud, can solve the problems of easy dam collapse and other problems, and achieve the effect of increasing storage capacity, fast dam body stability, and maintaining long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

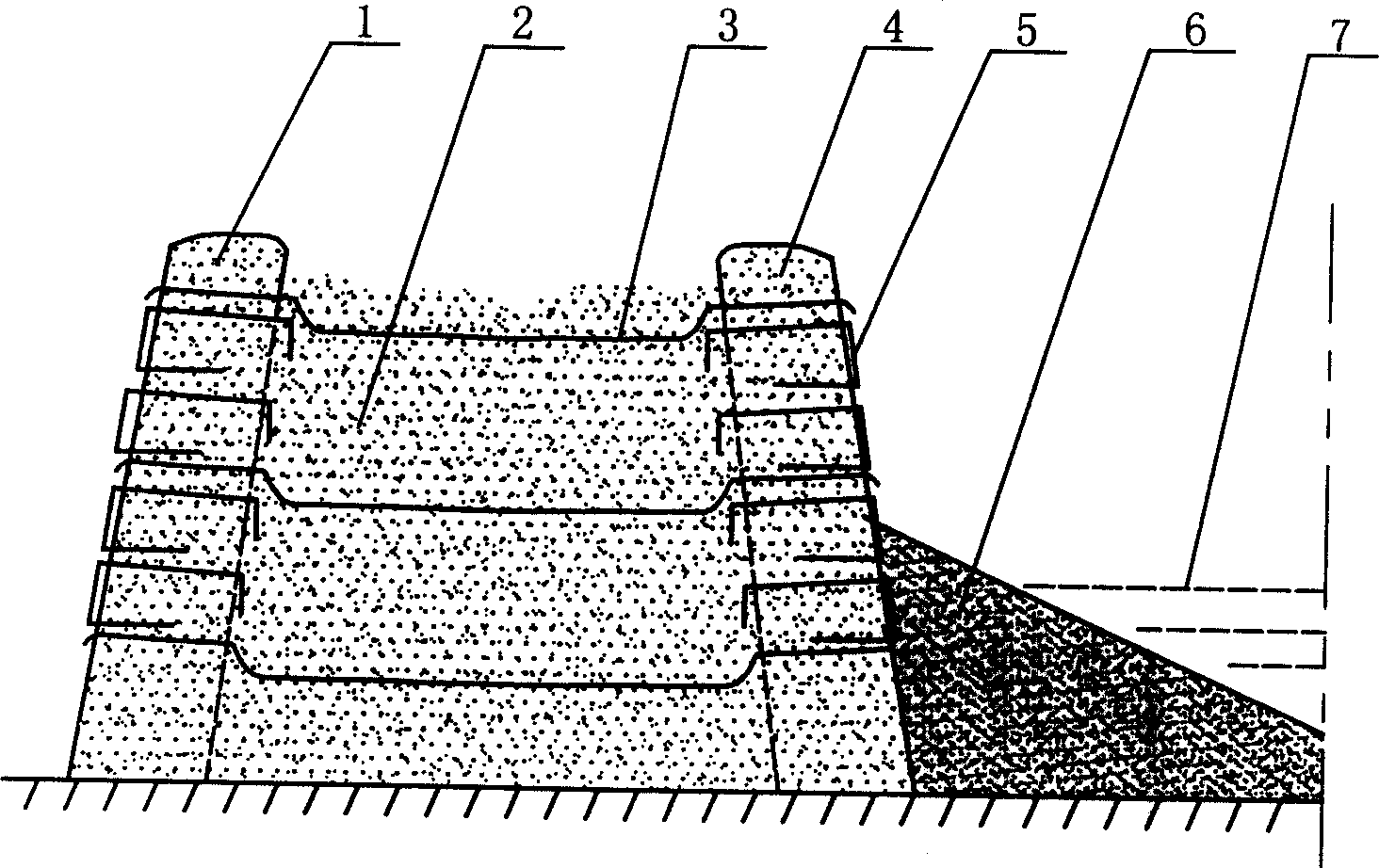

[0017] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

[0018] As shown in the figure, in the red mud rapid solidification dam building method described in the present invention, sub-dams 1, 4 and dam body 2 are piled up. During the dam-building process, the sub-dams are wrapped with plastic film 5 layer by layer from bottom to top to form sub-dams. Wrapping layer, the bottom edge of plastic film 5 is pressed below the sub-dam layer, and the top of plastic film 5 is pressed to the inboard of sub-dam from the outside, the top of sub-dam, and there are two sub-dam bodies 1, 1 and 2 in the dam body 2. The reinforced steel mesh 3 on 4 has a flange extending to the outside of the sub-dam, and the reinforced steel mesh 3 is bent downward between the two sub-dams 1 and 4.

[0019] In the red mud sub-dam construction process, gypsum or limestone solidifying agent of 3-5% by weight of the red mud is adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com