Display panel driving circuit and driving method

A display panel and drive circuit technology, applied in the direction of static indicators, instruments, etc., can solve the problems of response time difference, increase of resistance or electrostatic capacitance, inability to solve the unevenness of brightness, etc., and achieve the effect of correcting uneven brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

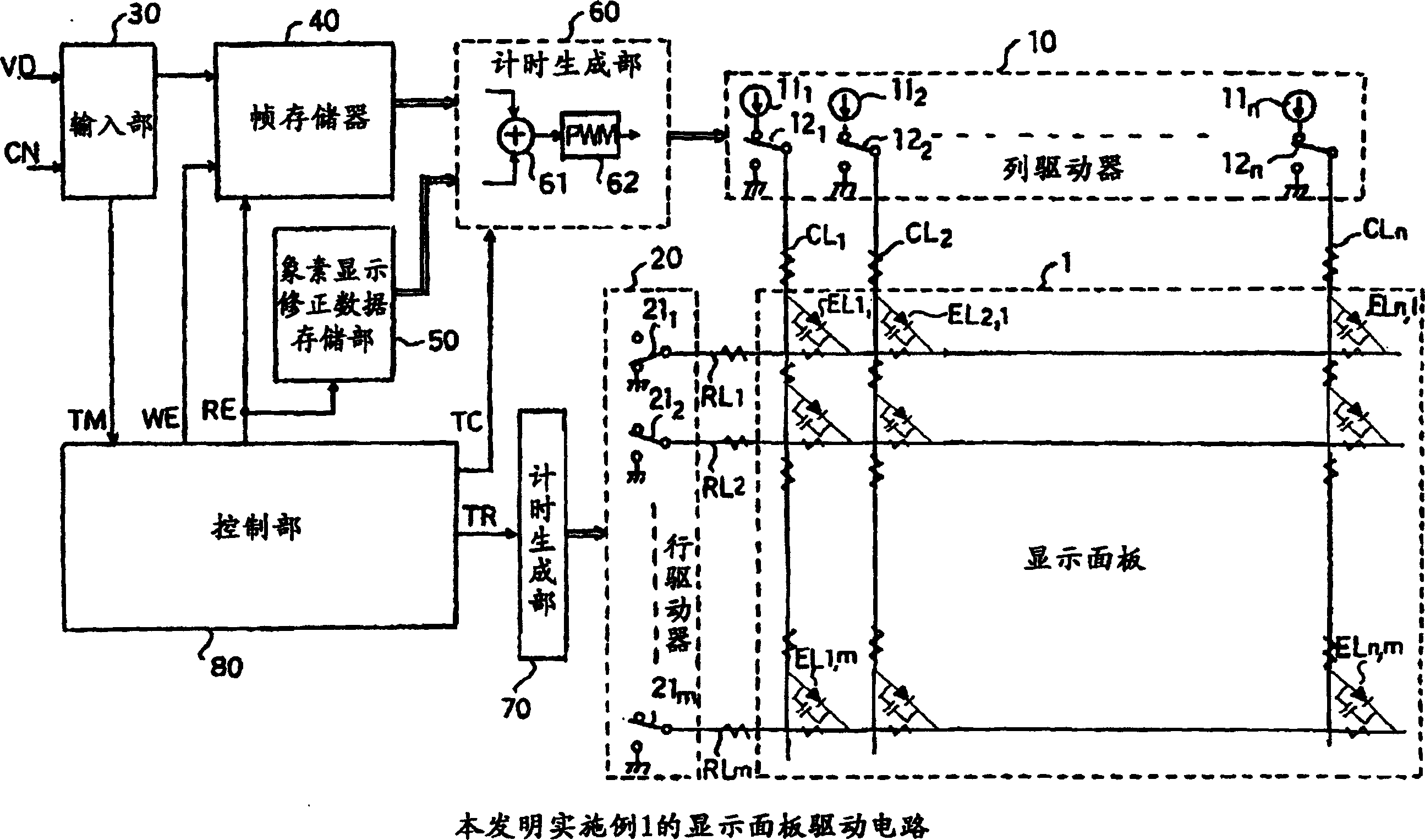

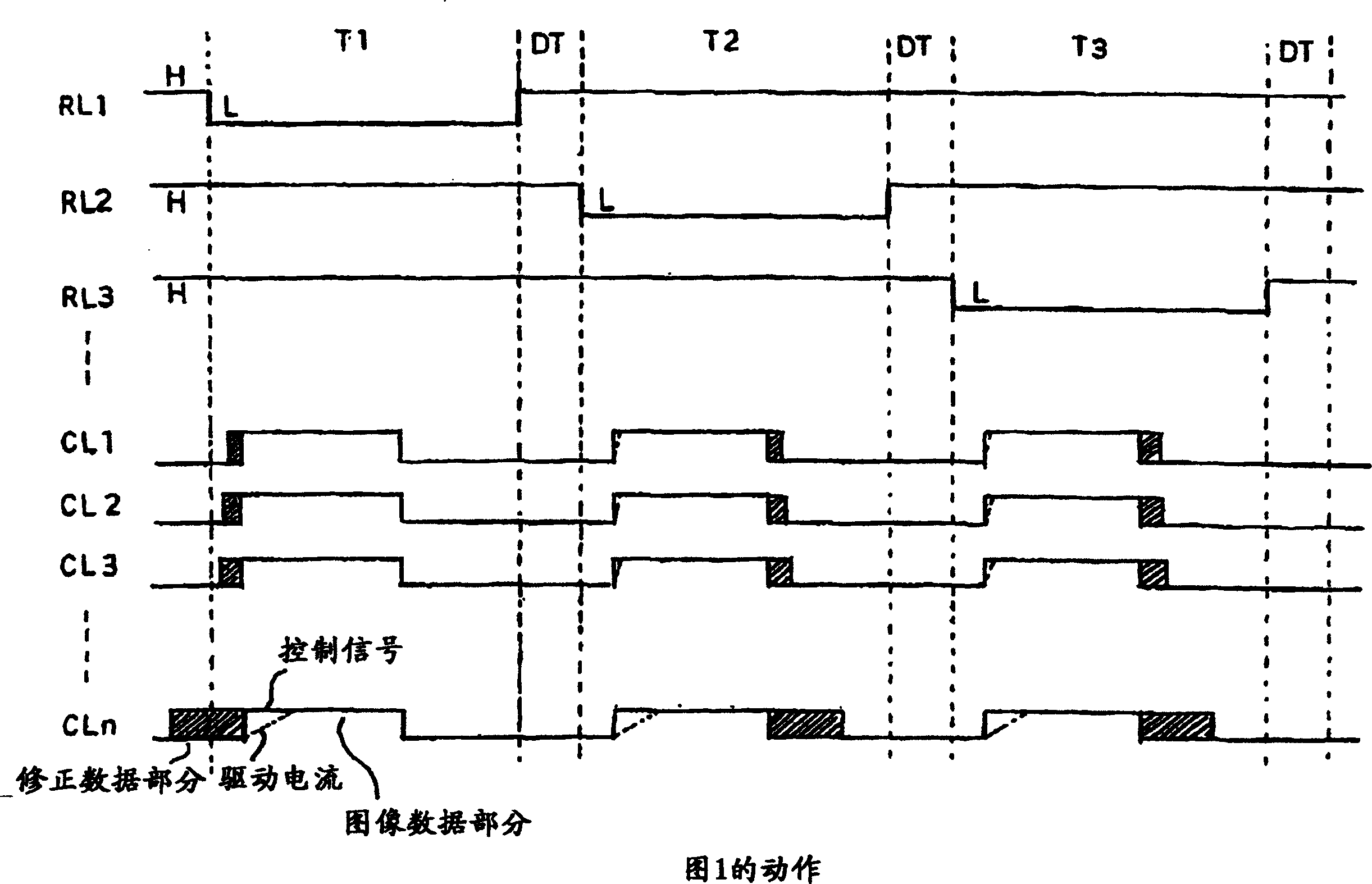

[0017] figure 1 It is a configuration diagram showing a display panel driving circuit according to Embodiment 1 of the present invention.

[0018] The display panel driving circuit has a column driver 10 and a row driver 20 for driving the display panel 1 . The display panel 1 is, for example, an organic EL panel, and has column lines CLi (i=1 to n) arranged in parallel at regular intervals and row lines RLj (j=1 to n) orthogonal to these column lines CLi and arranged in parallel at regular intervals. m). At each intersection of a column line CLi and a row line RLj, a light emitting element ELi,j is arranged.

[0019] In addition, although not a circuit element, in each of the column line CLi and the row line RLi, there is inevitably a distributed resistance component accompanying the wiring thereof. In addition, there must be electrostatic capacitance caused by the light emitting elements ELi,j provided between parallel column lines CLi, between row lines RLj, between inte...

Embodiment 2

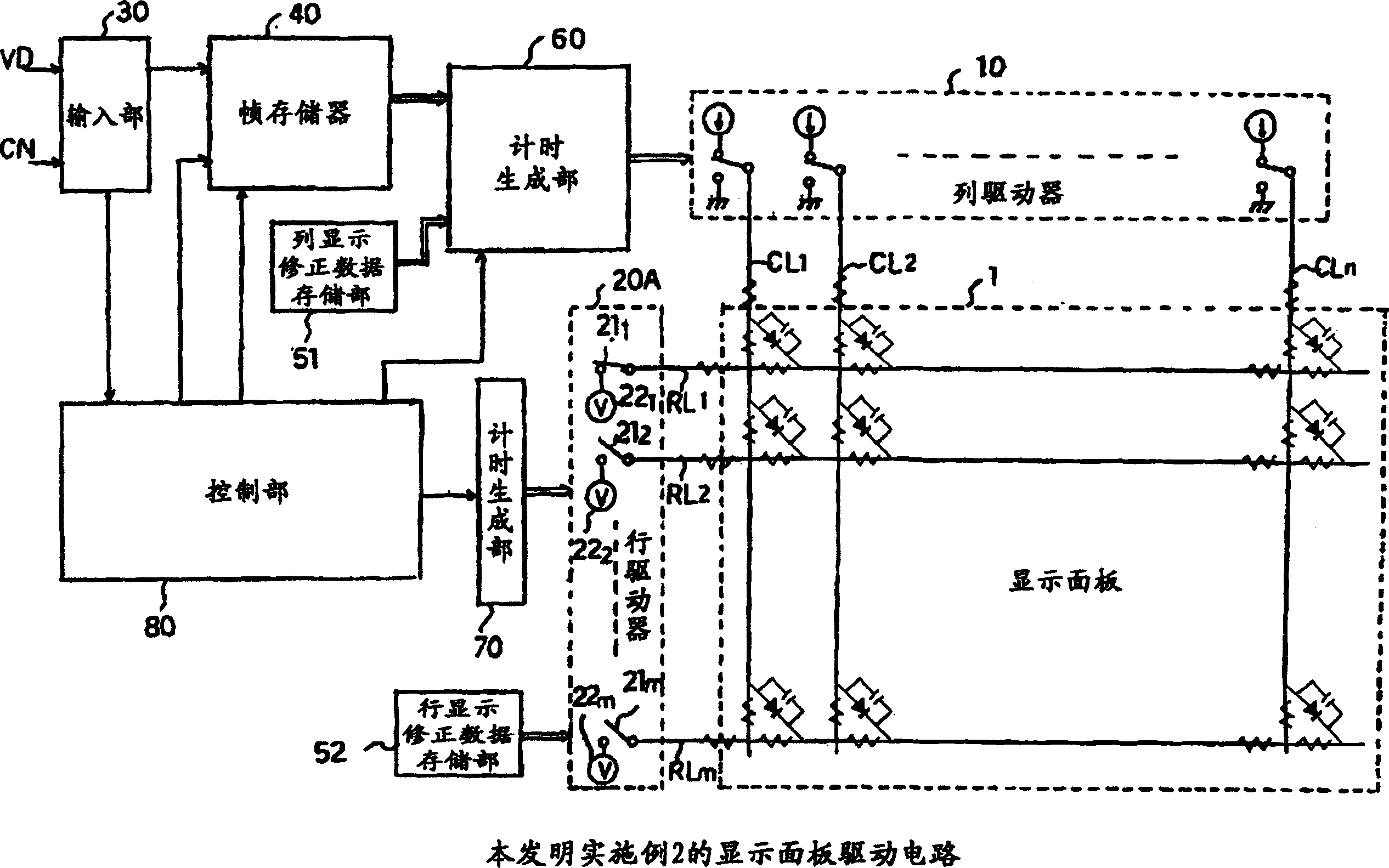

[0043] figure 2 It is a configuration diagram showing a display panel driving circuit according to Embodiment 2 of the present invention. right with figure 1 The same elements are attached with the same symbols.

[0044] The display panel driving circuit is provided with a column display correction data storage unit 51 and a row display correction data storage unit 52 instead of figure 1 The pixels in the display correction data storage unit 50, and instead of the row driver 20, a row driver 20A having a different function is provided.

[0045] The column display correction data storage unit 51 stores correction data for performing brightness correction due to differences in resistance or capacitance of the column lines CLi. figure 1 The pixel display correction data storage unit 50 stores correction data for each pixel in one frame, but the column display correction data storage unit 51 only stores correction data for the number of column lines CL. In addition, since thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com