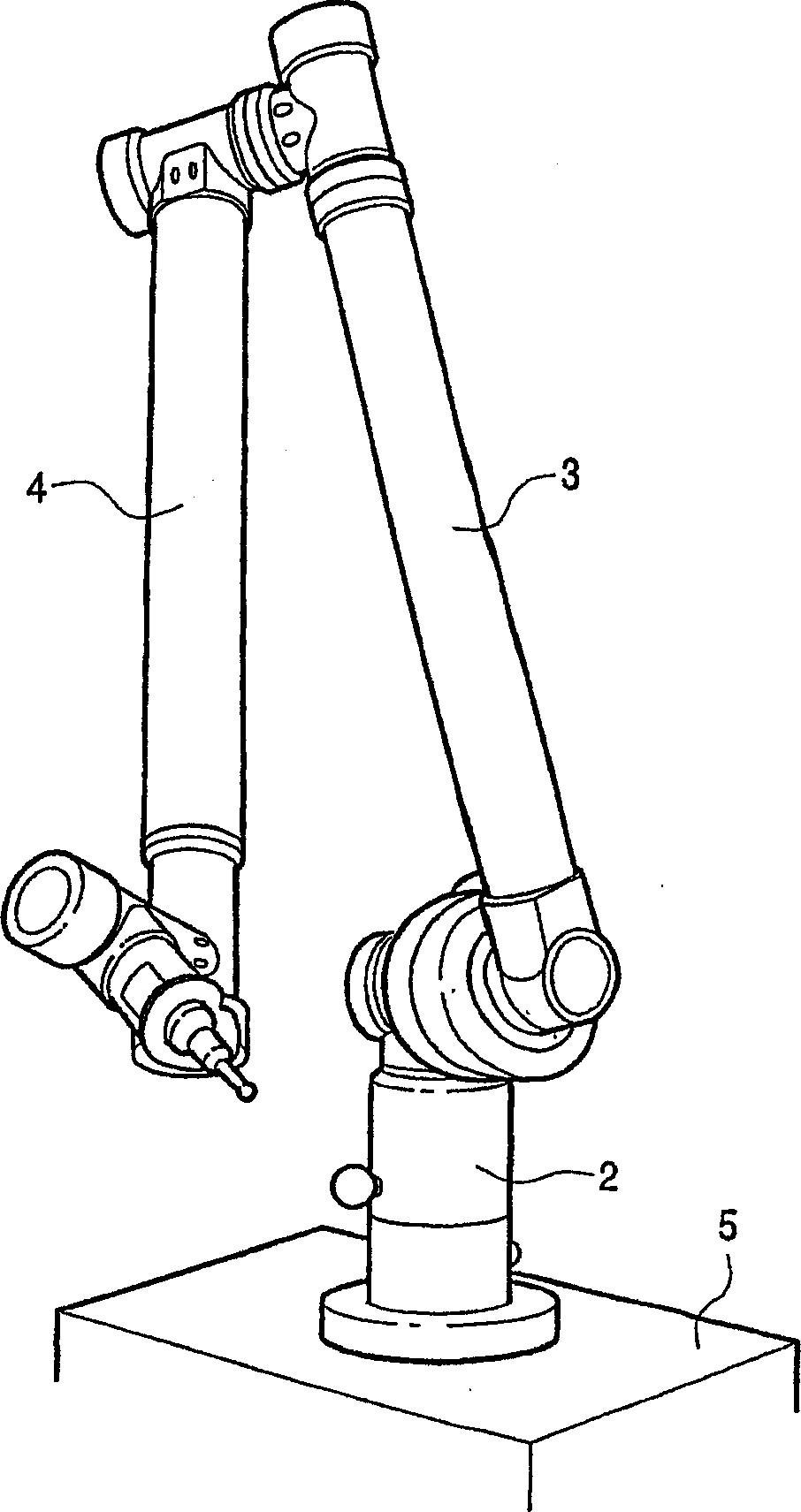

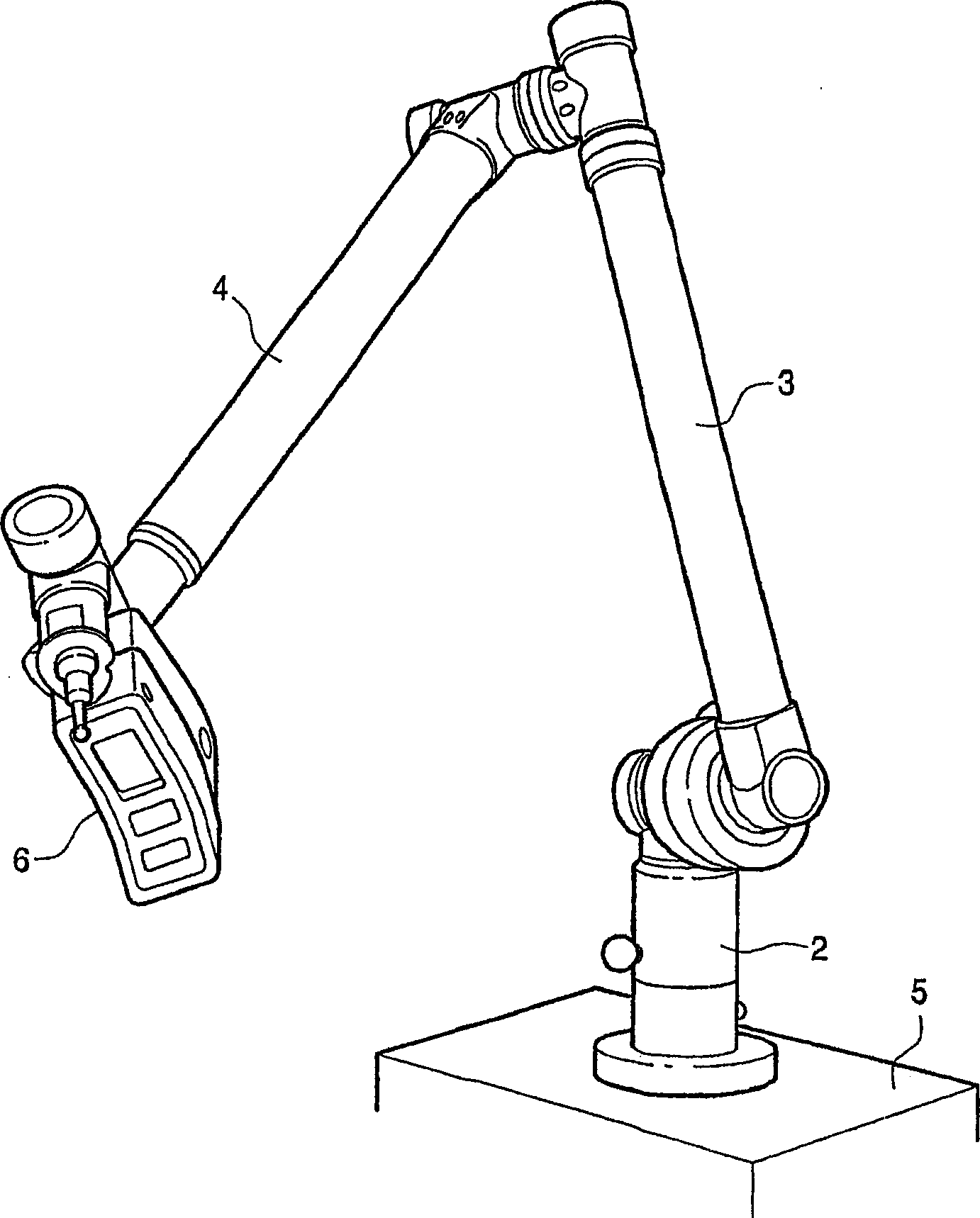

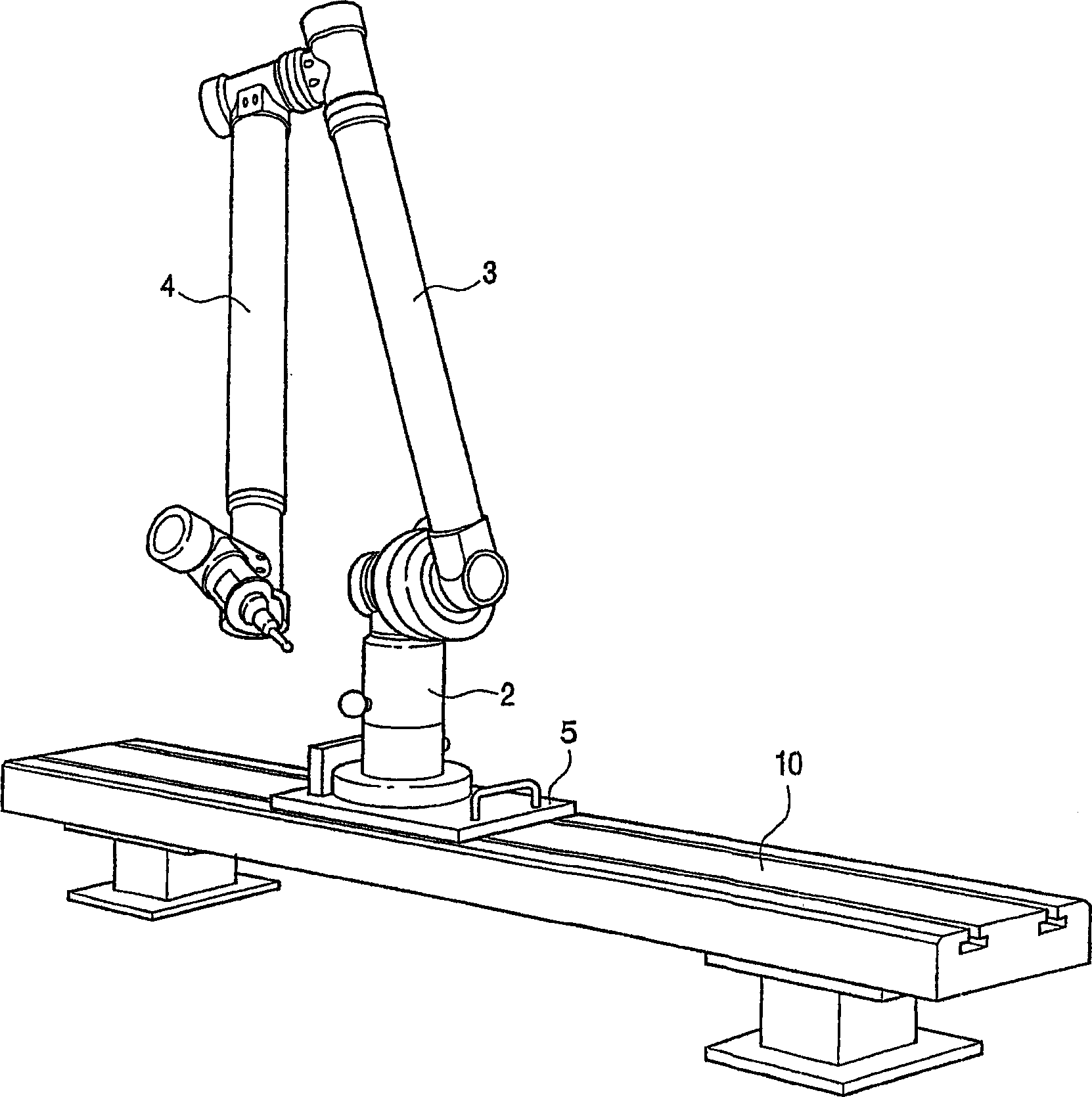

Method and apparatus for scanning corrosion and surface defects

A technology for scanning systems and surface conditions, which is applied in the field of forecasting systems for determining the safe service life of pipelines, determining and analyzing corrosion in or on pipelines, and predicting safe service life of pipelines. Unable to provide issues such as the remaining service life of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Corrosion is a naturally occurring phenomenon generally defined as the deterioration of a substance, typically a metal, or its properties due to a reaction with the environment. Corrosion can cause dangerous and costly damage to objects such as road bridges, gas and liquid transport pipelines, railways, motor vehicles, aircraft, ships, cranes, oil refineries, chemical, petrochemical and pharmaceutical production plants, nuclear power plants, etc. . Corrosion can lead to structural damage, loss of useful life, loss of capital investment and environmental damage and therefore requires detection, measurement, labeling and evaluation.

[0055] A common misconception is that corrosion damage continues at the same rate and with the same corrosion mechanism, which is not the case. Corrosion occurs in stages and involves specific conditions, for example caused by fluctuations in temperature, or by changing product chemistry and interactions between piping materials. The sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com