Gas permeable substrate and solid oxide fuel cell using the same

A gas permeable, substrate technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell grouping, etc., can solve the problem of difficulty in reducing the weight and thickness of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

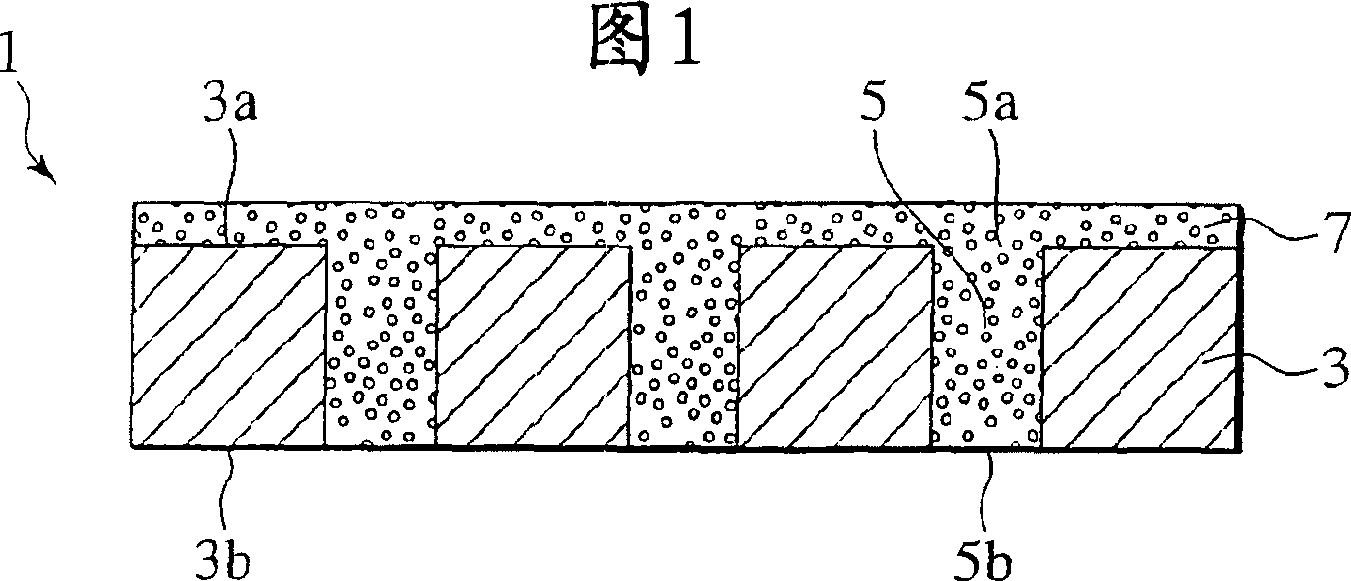

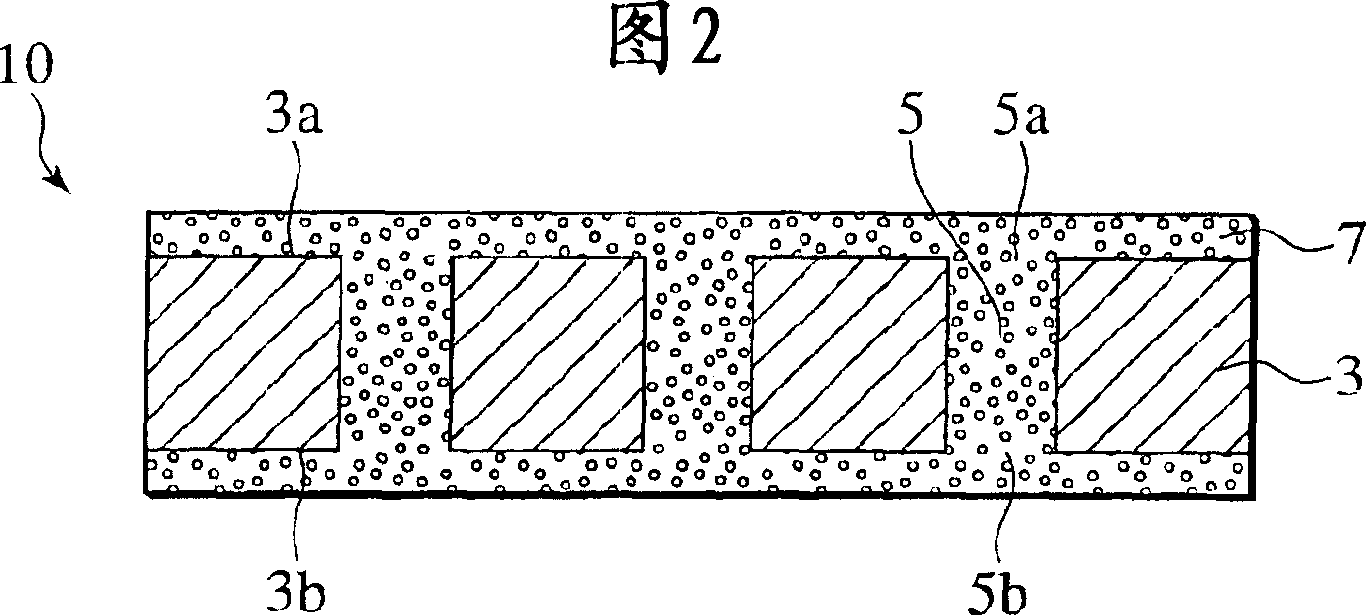

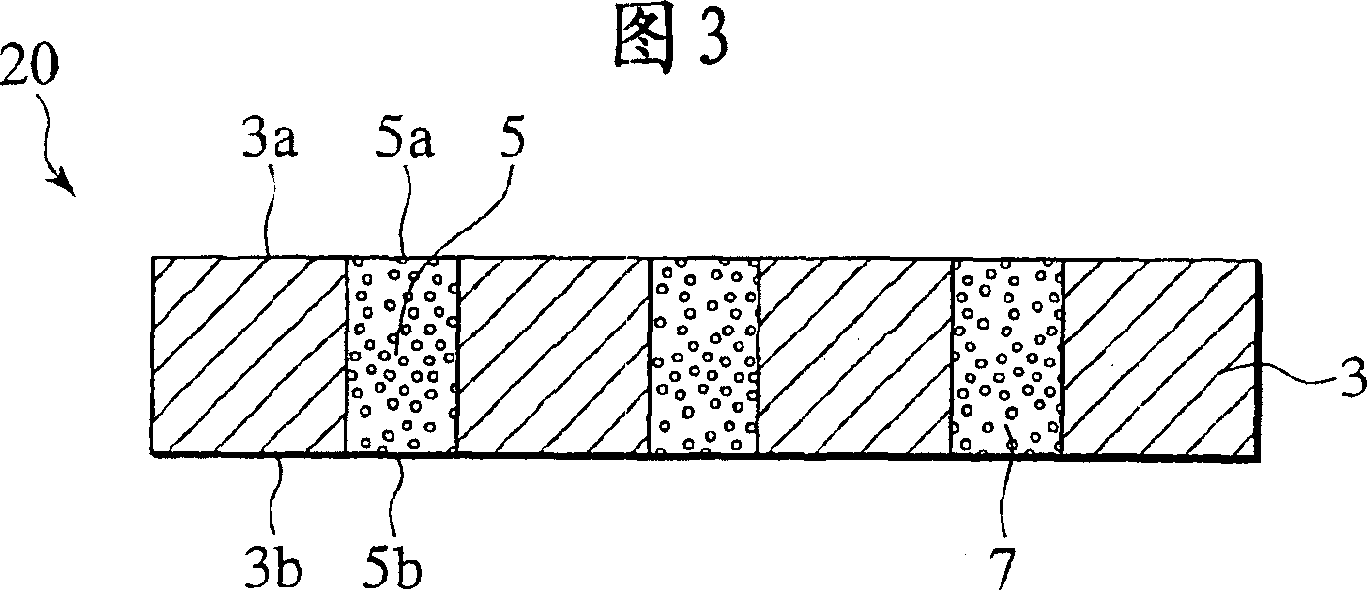

[0027] The gas permeable substrate of the present invention comprises: a porous metal plate provided with a plurality of holes constituting openings on the upper surface and / or lower surface thereof; and particles filled in the holes. The gas permeable substrate is characterized in that at least one of the upper surface and the lower surface of the porous metal plate is substantially smooth. Specific embodiments are already shown in FIGS. 1 to 3 . As shown in FIG. 1, a gas permeable substrate 1 of the present invention comprises a porous metal plate 3 and a particle layer 7. As shown in FIG. The porous metal plate 3 includes a plurality of holes 5 based on which a plurality of openings 5 a and 5 b are formed on the upper surface 3 a and the lower surface 3 b of the porous metal plate 3 . Fine particles are filled in these holes 5 to form a fine particle layer 7, and the upper surface thereof is processed to be smooth. In this way, the air-permeable substrate 1 of the prese...

no. 2 example

[0040] A solid oxide fuel cell (SOFC) using the gas permeable substrate of the present invention will be described in detail below. Regarding the structure of the solid oxide fuel cell in this embodiment, the same components as those in the first embodiment are denoted by the same reference numerals in the drawings, and their description will not be repeated.

[0041] The SOFC of the present invention can be made using the gas permeable substrate according to the first embodiment. Specifically, the SOFC is formed by stacking a plurality of individual cells, wherein each individual cell includes a power generating element stacked on the upper surface of a gas permeable substrate and / or on the lower surface. Since the surface of the gas permeable substrate of the present invention is smooth, it is possible to provide a light-weight and small-thick power generating element on the entire gas permeable substrate, and also to obtain SOFC which can operate at low temperature. The f...

example 1

[0053] As shown in Figure 1, for porous metal plate 3, the hole of a plurality of aperture φ=0.1 millimeter can be processed by utilizing photolithography on an etched plate, and wherein this etched plate is made by No. SUS304 material, And the thickness is 0.1mm. Next, for the particle layer 7, a fuel electrode material paste composed of Ni-SDC and having a particle size of 2 μm was applied to the porous metal plate 3 with a thickness of 0.12 mm by the screen printing method, and then, hydrogen reduction at 1050° C. It was baked under the atmosphere. Thus, the air-permeable substrate shown in Fig. 1 was produced. Figure 10 An enlarged photograph of a cross-section of such a gas-permeable substrate is shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com