Novel steel-concrete combined beam

A technology for reinforced concrete slabs and composite beams, which is applied in the field of bridges and building support components and composite beams. It can solve the problems of manpower consumption, working hours, inability to fully guarantee, and affect the safety and reliability of composite beams, and achieve large bonding force and shear resistance. Strong cutting ability and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

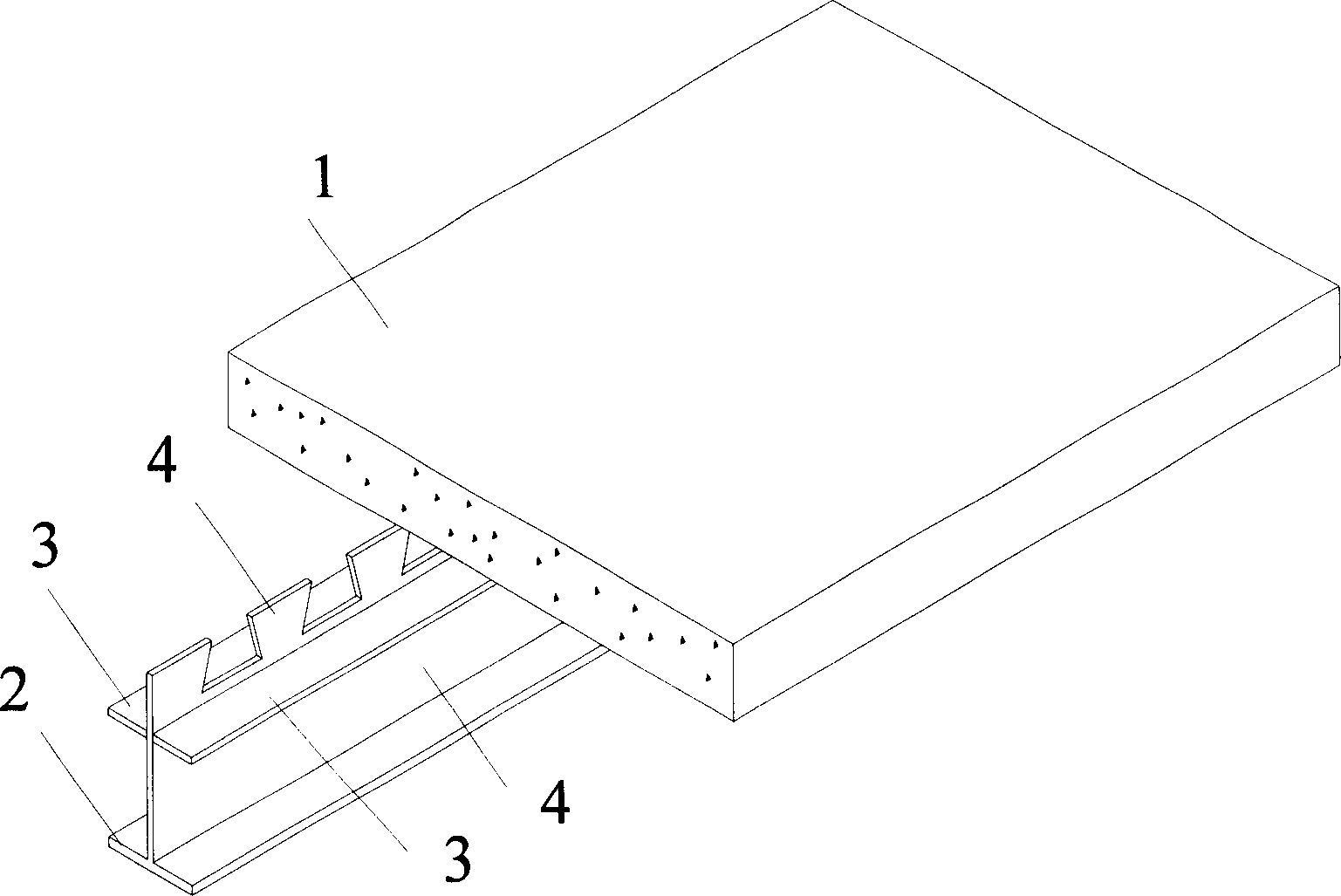

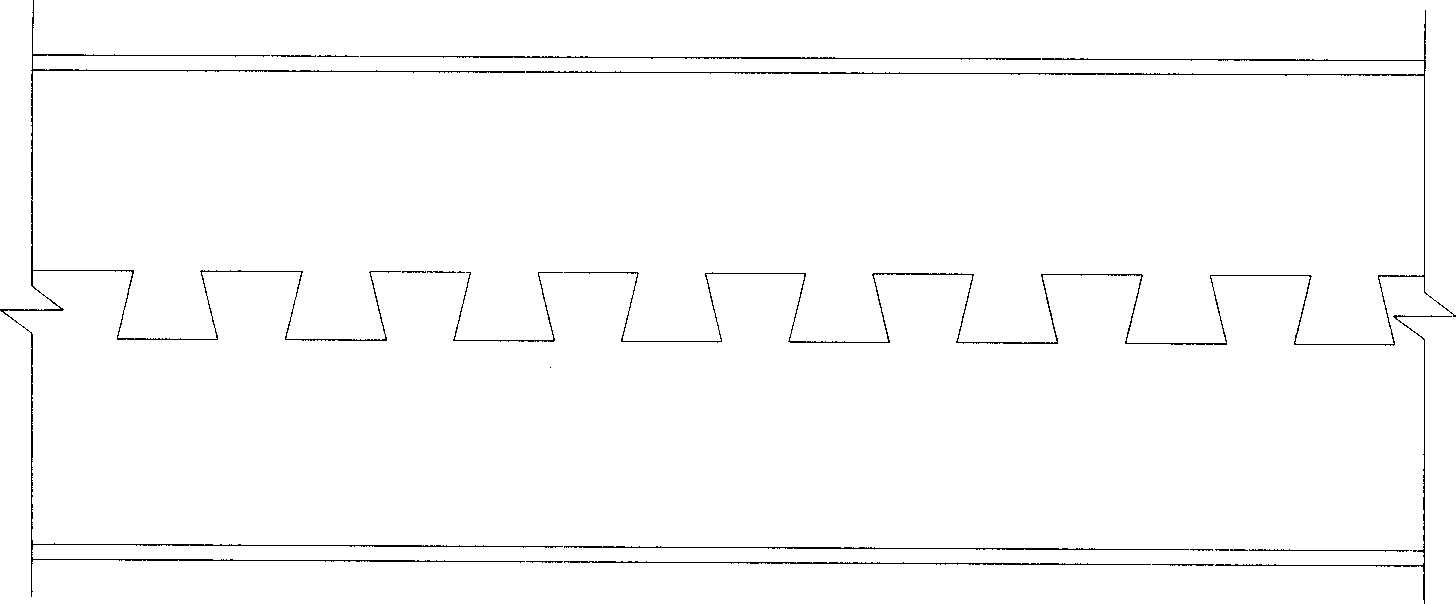

[0017] like figure 1 , image 3 As shown, an H-shaped steel-concrete composite beam of the present invention comprises a reinforced concrete slab 1, a lower flange of the steel beam 2, two upper flanges of the steel beam 3 and a steel beam web 4, and one side of the steel beam web 4 is sawtooth The shape of the sawtooth is an inverted isosceles trapezoid. The sawtooth protrudes from the upper flange of the steel beam. The sawtooth edge of the web is cut from the H-shaped steel web along the broken line. The entire sawtooth extends into the upper reinforced concrete slab to form the shear connection of the composite beam. The upper flange 3 of the 2 steel beams is composed of two steel plates, and the height is located at the root of the sawtooth. The lower flange 2 of the steel beam and the web 4 of the steel beam are the lower flange and web of H-beam, and the 2 upper flanges and the web are welded by welding connect.

Embodiment 2

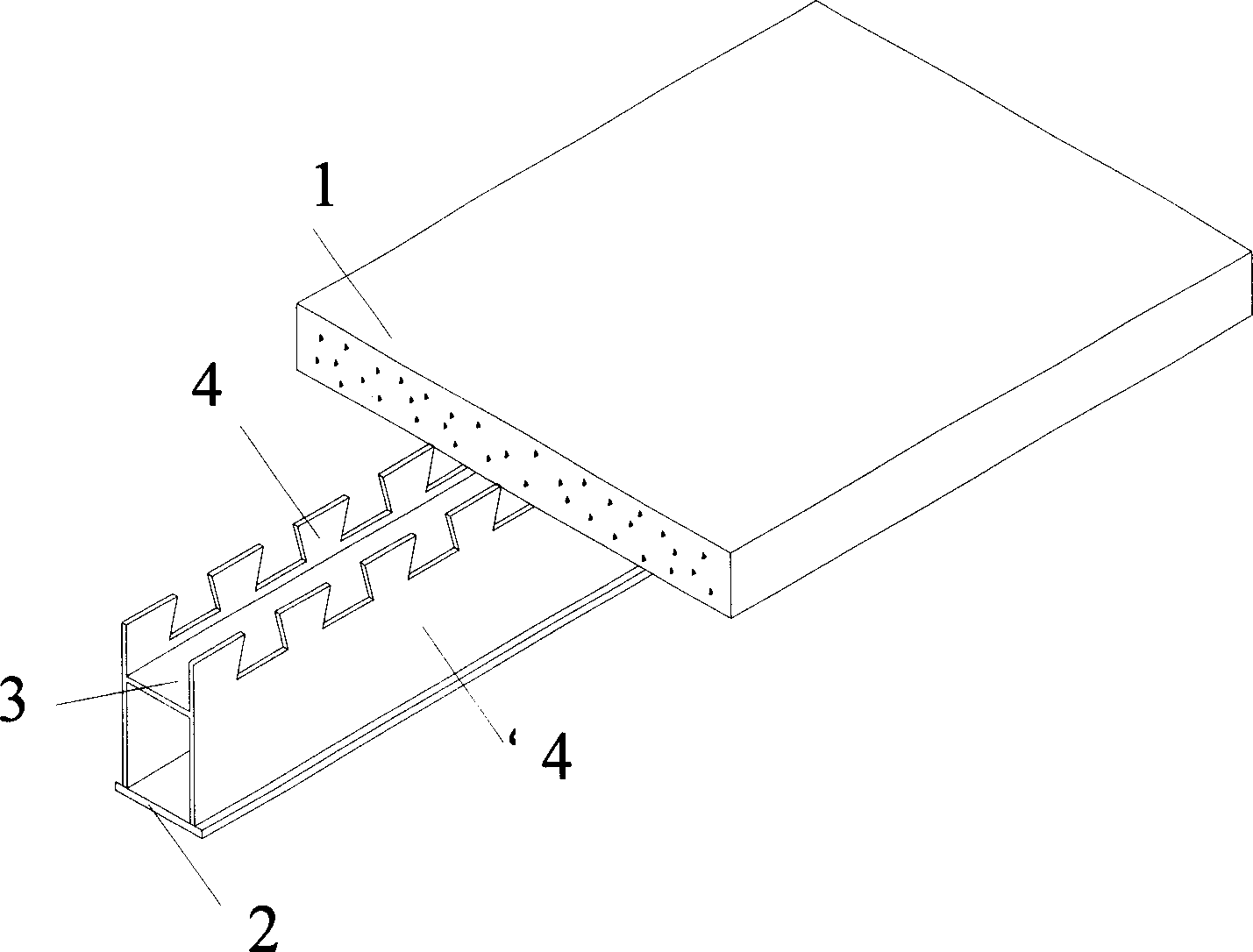

[0019] like figure 2 , Figure 4 As shown, a box-shaped steel-concrete composite beam of the present invention includes a reinforced concrete slab 1, a lower flange 2 of a steel beam, an upper flange 3 of a steel beam and two steel beam webs 4, and one side of the steel beam web 4 is a belt The sawtooth edge, the shape of the sawtooth is an inverted isosceles trapezoid, the sawtooth protrudes from the upper flange of the steel beam, the sawtooth edge of the web is cut from the steel plate along the broken line, the upper flange 3 of the steel beam is located between the two sawtooth edge webs, and the height is located at the root of the sawtooth, and the upper Flange and 2 webs are connected by welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com