Vegetation ecological concrete precast block and preparation method thereof

A technology of ecological concrete and prefabricated blocks, applied in application, cultivation, agriculture, etc., can solve the problems of inconvenient laying and inability to carry out industrial production, and achieve the effect of convenient laying, effective treatment and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

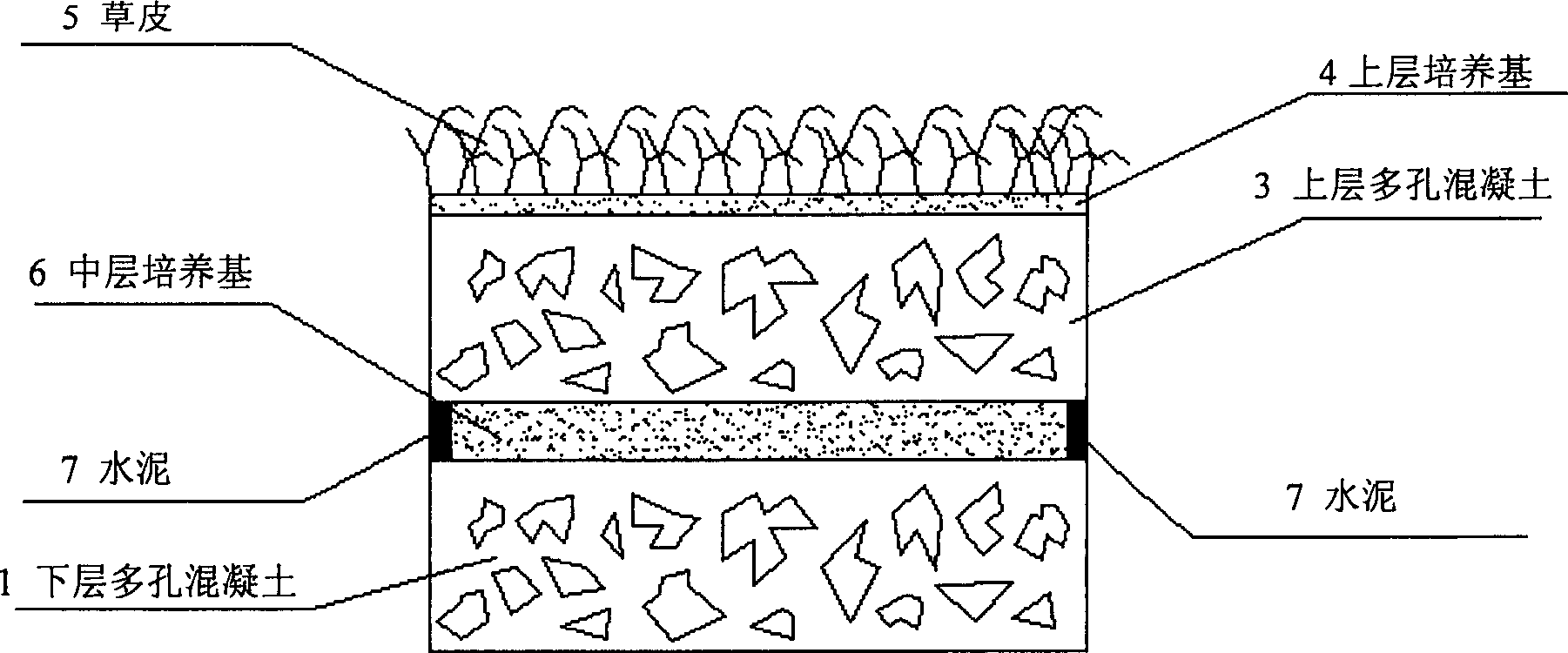

[0021] Embodiment one: referring to accompanying drawing, this vegetation ecological concrete prefabricated block is a multi-layer planting base material, is made of the top layer of culture medium layer 4 suitable for vegetation growth, the upper porous concrete layer 3 suitable for vegetation root system penetration, and the layer suitable for vegetation root system growth. The middle culture medium layer 2 and the lower porous concrete layer 1 suitable for the penetration of vegetation roots constitute a prefabricated block of four-layer structure. The thicknesses of the four layers of the above-mentioned prefabricated block are respectively: the top culture medium layer 4 is 3mm, the upper porous concrete layer 3 is 5cm, the middle waste brick medium mixed layer 2 is 5mm, and the lower porous concrete layer 1 is 5cm; the prefabricated length and width 20cm respectively. The surrounding wall of the prefabricated block has a bonded and strengthened structure layer composed o...

Embodiment 2

[0026] Embodiment 2: See also the accompanying drawings. This embodiment is basically the same as the above-mentioned embodiment, the difference lies in the size of the prefabricated block and the ratio of raw materials. In this embodiment, the thicknesses of the four layers of the prefabricated block are respectively: the top culture medium layer 4 8mm, the upper porous concrete layer 3 is 8cm, the medium culture medium mixing layer 6 is 15mm, and the lower porous concrete layer 1 is 8cm; the prefabricated length and width are respectively 30cm, and the wall cement thin layer 7 thickness is 4mm.

[0027] The raw materials of the upper and lower porous concrete layers 3 and 1 are proportioned by weight as follows: aggregate 100g, cement 65g, slag micropowder 115g, water 500g, and water reducer 55g.

[0028] The raw material composition and weight ratio of the medium medium layer 6 are: 100g of peat, 20-30g of grass clippings, and 2-3g of additives.

[0029] The raw material co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com