Electromagnetic eddy flow downspout

A nozzle and electromagnetic technology, applied in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of misalignment of sliding nozzles, large consumption of refractory materials, application limitations, etc., to prevent meniscus disturbance and save money. Refractory materials, the effect of mentioning yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

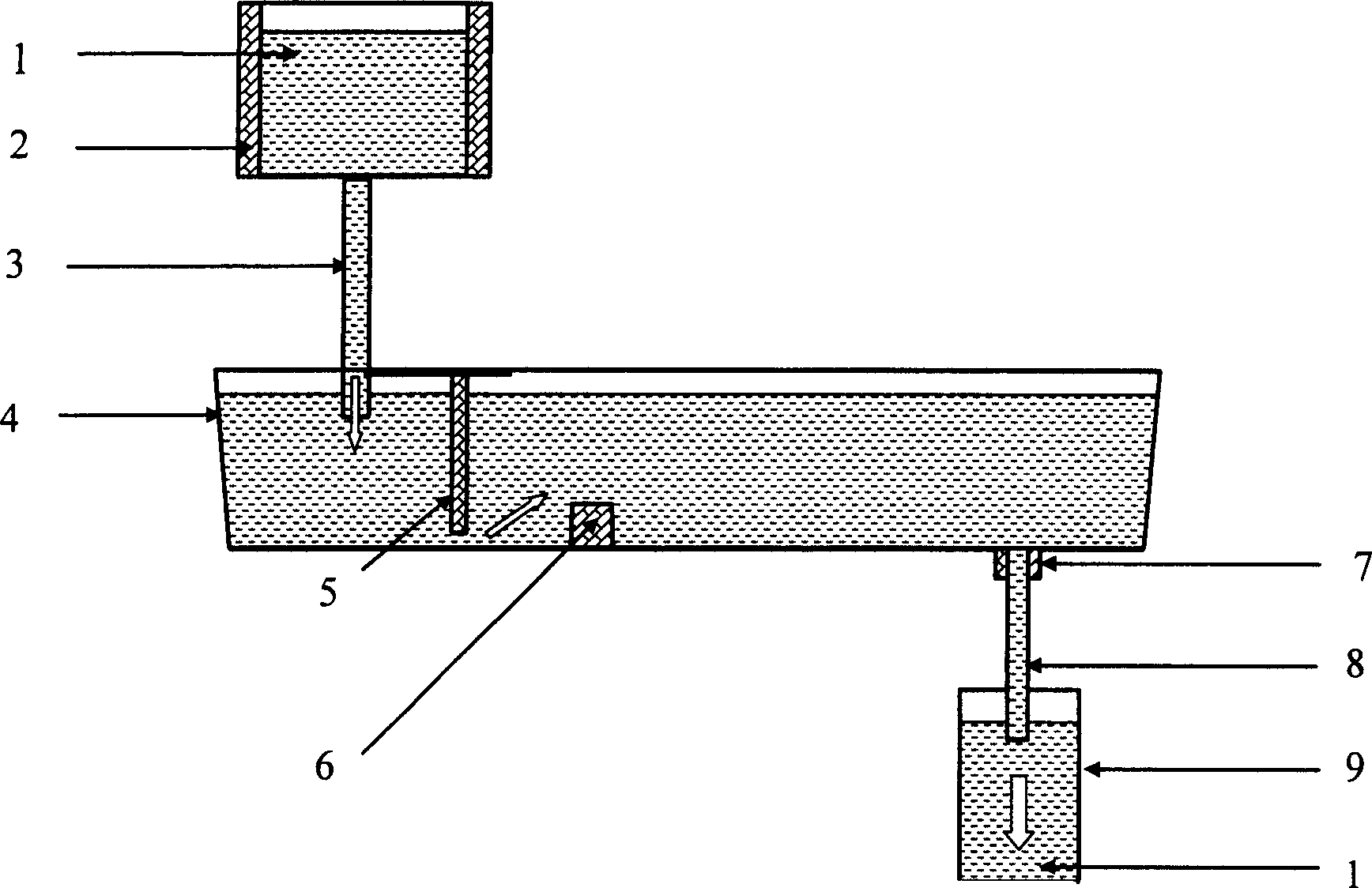

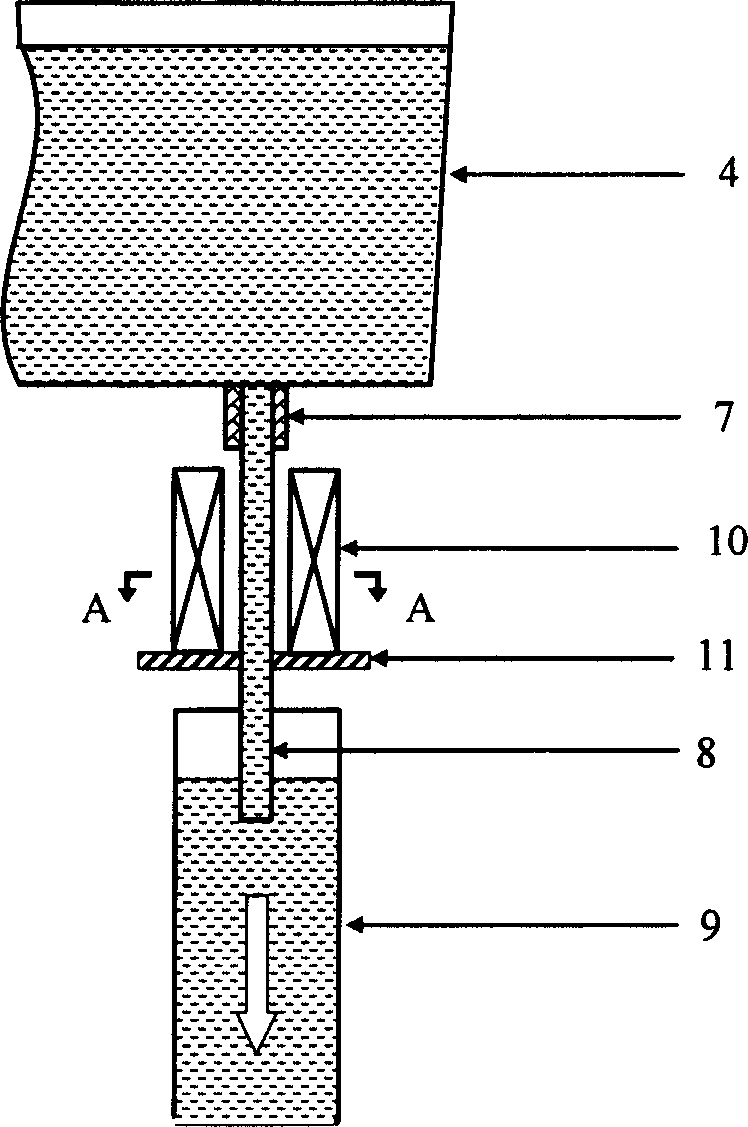

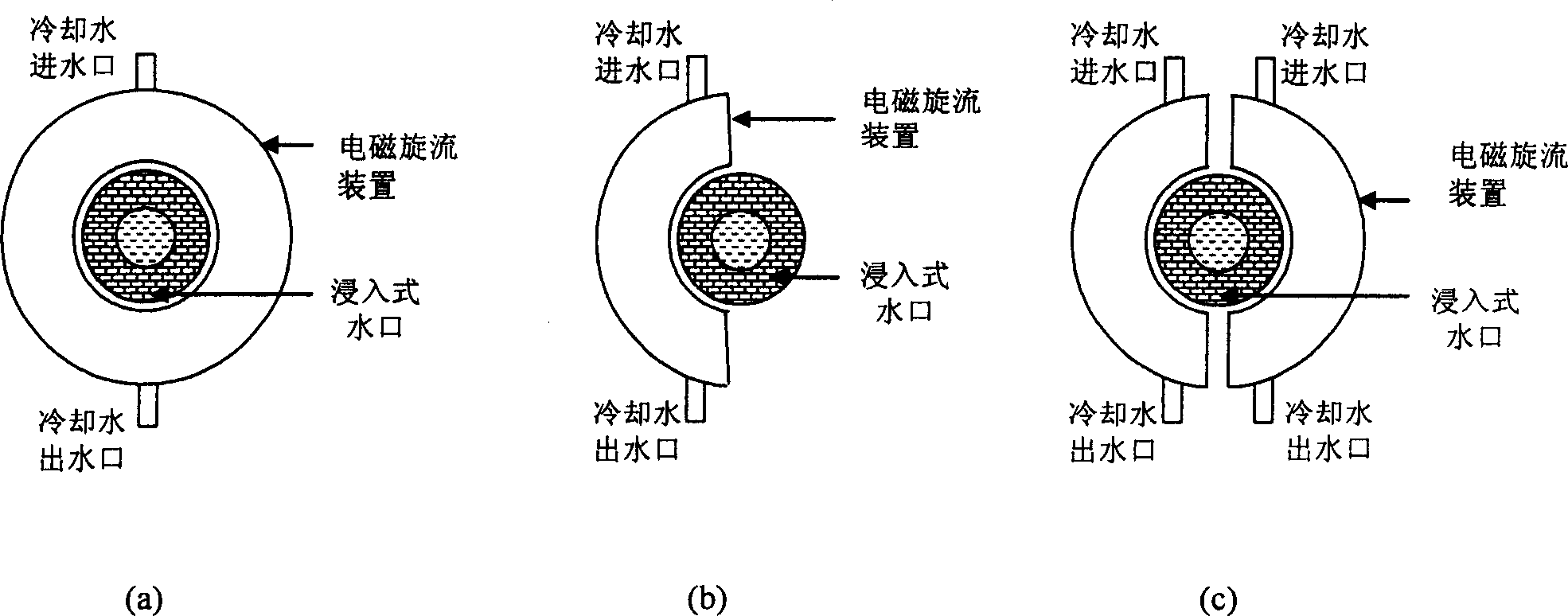

[0032] Example 1 is an electromagnetic swirl nozzle suitable for round billet continuous casting process. The round billet continuous casting mold is round ( Figure 5 c), single-hole straight cylindrical nozzles are mostly used ( Figure 5 b). The mobile electromagnetic swirl device can adopt a semi-circular ring type (180 degrees, Figure 5 a). Its magnetic induction intensity is 10 -4 Tesla.

Embodiment 2

[0033] Embodiment 2 is also an electromagnetic swirl nozzle suitable for round billet continuous casting process. The round billet continuous casting mold is round ( Figure 6 c), single-hole straight cylindrical nozzles are mostly used ( Figure 6 b). The mobile electromagnetic swirl device can adopt a split ring electromagnetic swirl device (360 degrees, Figure 6 a). Its magnetic induction intensity is 10 -2 Tesla.

Embodiment 3

[0034] Example 3 is suitable for billet continuous casting process. The billet continuous casting mold is square ( Figure 7 c), more cylindrical double-sided outlets are used ( Figure 7 b). The mobile electromagnetic swirling device of this embodiment can adopt a semicircular ring type (180 degrees, Figure 7 a). Its magnetic induction intensity is 10 -1 Tesla.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com