A high-temperature liquid blast furnace slag waste heat recovery device and its waste heat recovery method

A waste heat recovery device and waste heat recovery technology, applied in furnaces, furnace components, waste heat treatment, etc., can solve the problems of refractory material consumption, high energy consumption, non-compliance with energy-saving emission reduction policies and low-cost production and operation requirements, etc. Refractory material, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

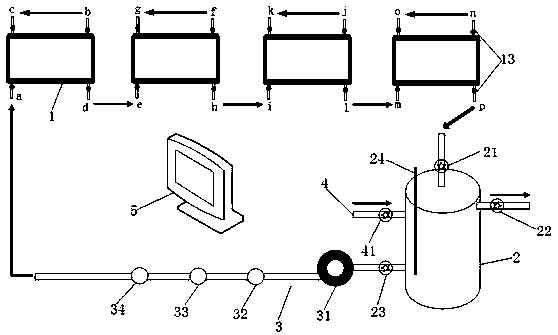

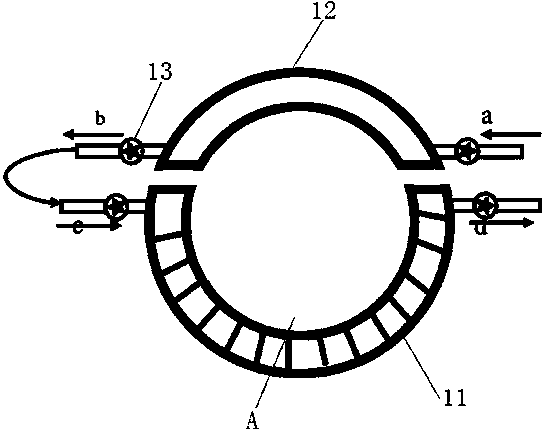

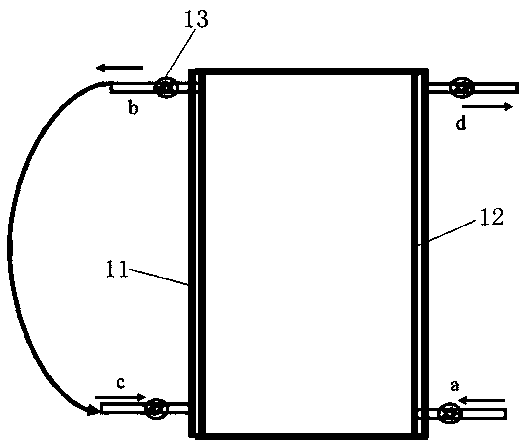

[0023] refer to figure 1 , the high-temperature liquid blast furnace slag waste heat recovery device of this embodiment includes a heat exchange unit composed of four heat exchange modules 1 connected in series, specifically, refer to figure 2 , 3 , the heat exchange module 1 is a split structure design, the main body shape is a hollow cylinder, the high-temperature liquid blast furnace slag flows in the hollow channel A, and the bottom 11 is fixed in the slag ditch (not shown in the figure). The high-temperature liquid blast furnace slag of the embodiment flows in the channel A of the bottom 11. In order to absorb the radiant heat of the high-temperature liquid blast furnace slag and keep the high-temperature liquid blast furnace slag warm, the heat exchange module 1 of this embodiment also has a top 12, and the top 12 is connected to the The bottom 11 is open and closed, and the top 12 can also be turned over. In this embodiment, the heat exchange module 1 with such a str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com