Inflating expanded truss for outer space use

An inflatable deployment and space technology, applied in the field of space trusses, can solve problems such as high cost, inconvenient operation, and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

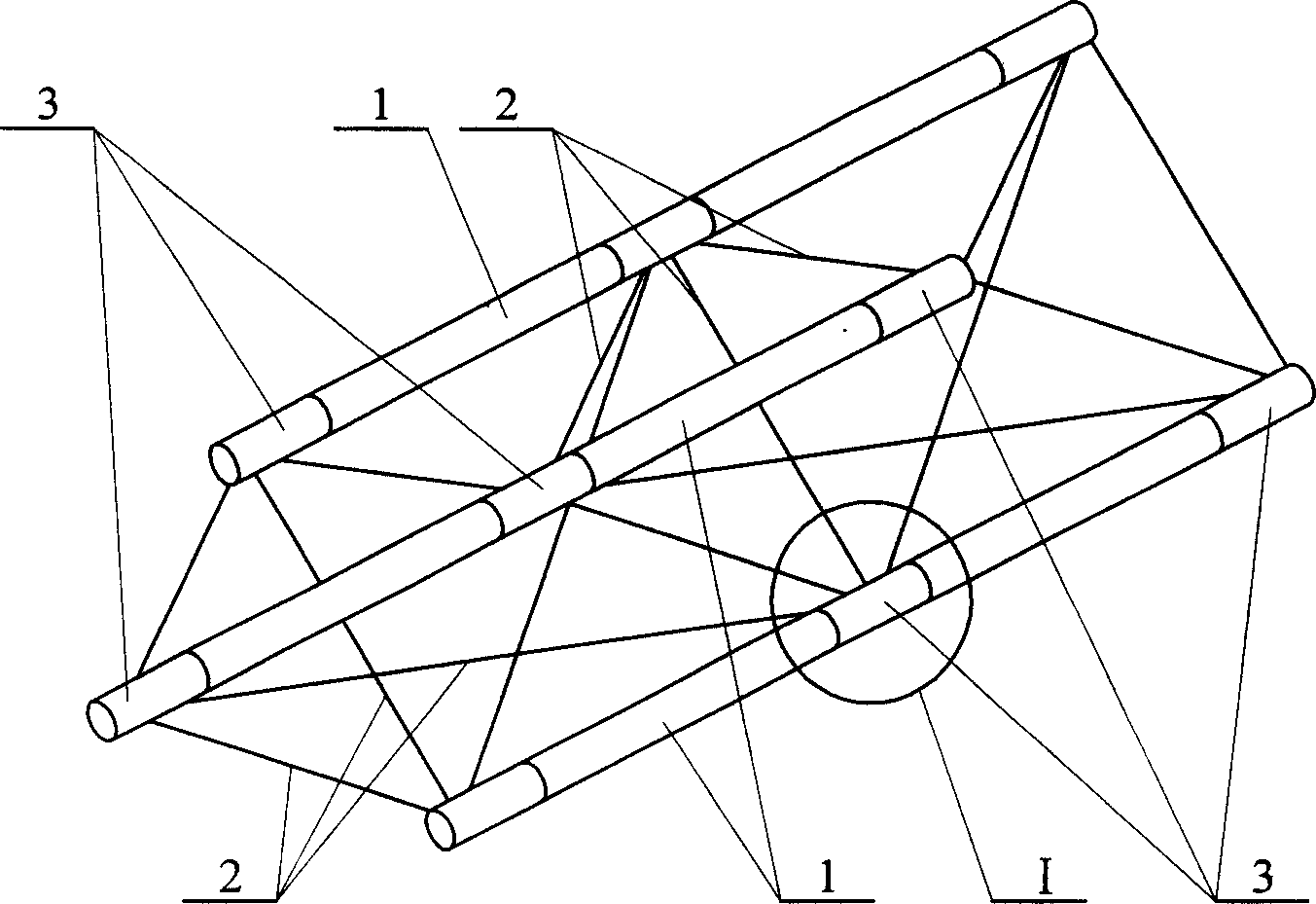

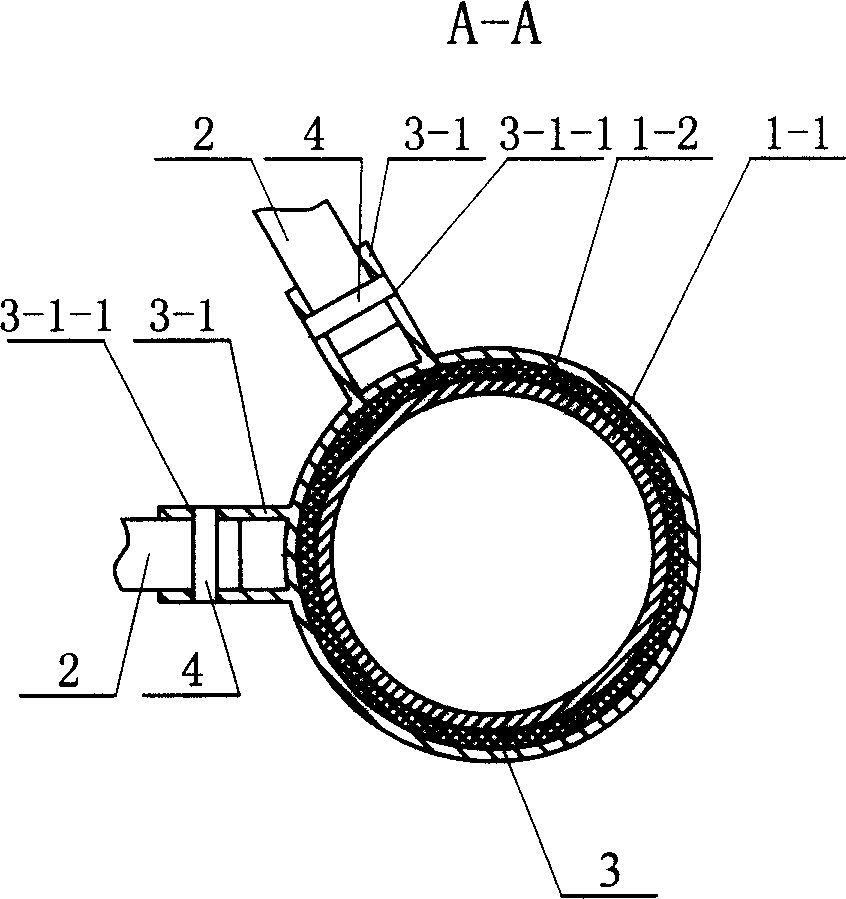

[0005] Specific implementation mode one: (see Figure 1-Figure 2 ) This embodiment consists of at least three inflatable expansion tubes 1 and several heat-curable support rods 2. The inflatable expansion tube 1 is composed of an inner lining layer 1-1 and a heat-curable layer 1-2. The heat-curable layer 1-2 Set on the outer surface of the inner lining layer 1-1, the inner lining layer 1-1 is a polyimide plastic film or rubber film, the heat-curable layer 1-2 is a pre-impregnated epoxy resin fabric; the heat-curable support rod 2 Fixedly connected between every two inflatable expansion tubes 1, the heat-curable support rod 2 is a carbon fiber rod pre-impregnated with epoxy resin. The epoxy resin prepreg requires less energy for curing, and has the advantages of excellent mechanical properties, good insulation performance, and good corrosion resistance after thermal curing. The thermally curable layers 1-2 and thermally curable support rods 2 described in this embodiment Epoxy...

specific Embodiment approach 2

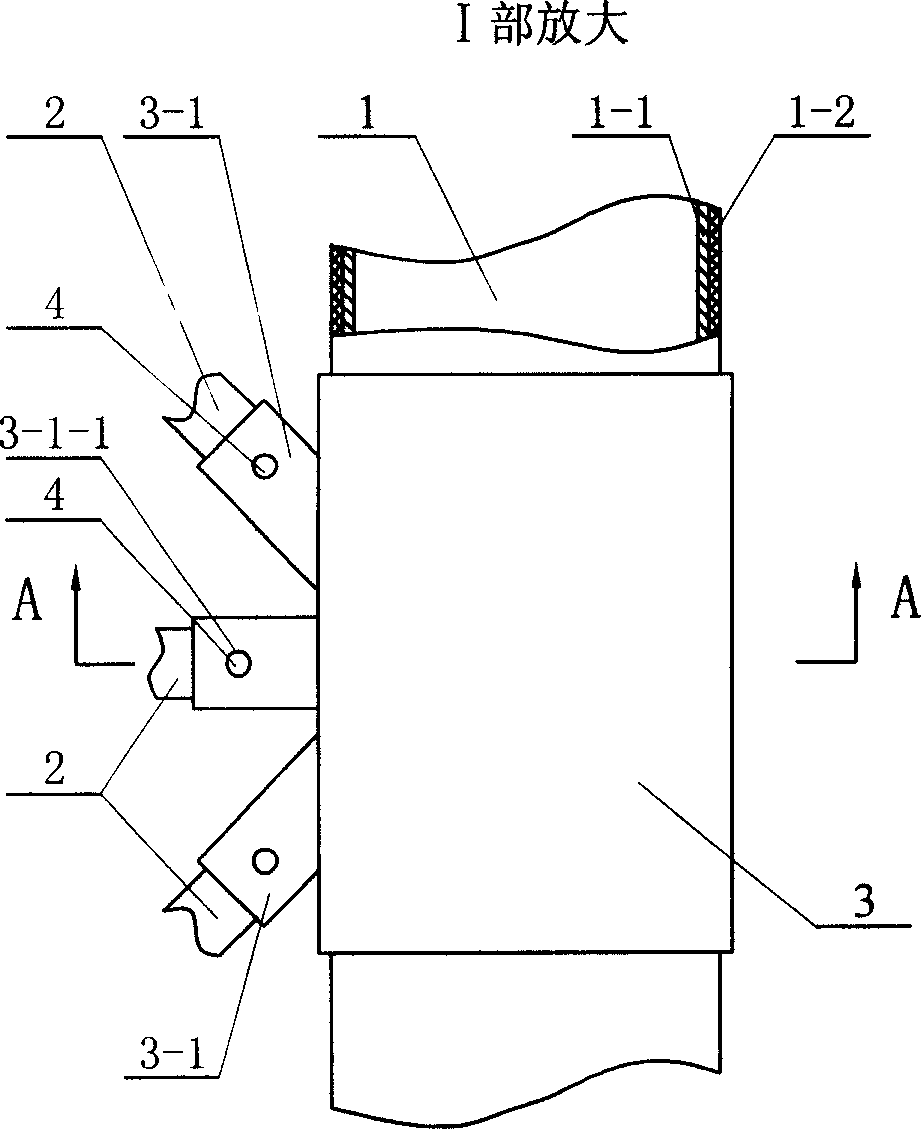

[0006] Specific implementation mode two: (see Figure 1-Figure 3 ) The difference between this embodiment and the first embodiment is that it adds a rigid connection sleeve 3 and a pin 4, and the rigid connection sleeve 3 is set on the outside of the inflatable expansion tube 1 and fixed on the inflatable expansion tube 1. The heat-curable support rod 2 The connection of the rigid connection sleeve 3 is fixed with a support rod installation tube 3-1, and the support rod installation tube 3-1 is provided with a radial pin hole 3-1-1, and the plurality of heat-curable support rods 2 The two ends of each are respectively placed in the support rod installation tube 3-1 on the rigid connection sleeve 3 and glued together, and the pin 4 is placed in the radial pin hole 3-1-1 on the support rod installation tube 3-1 and passed through The ends of the struts 2 can be cured with heat. Other compositions and connections are the same as in the first embodiment. Due to the addition of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com