Thermal transfer printer

A printing press and thermal transfer technology, applied in printing, inking device and other directions, can solve the problems of longer size B, higher image printing costs, and higher operating costs, and achieve size reduction, low printing costs, and reduced operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

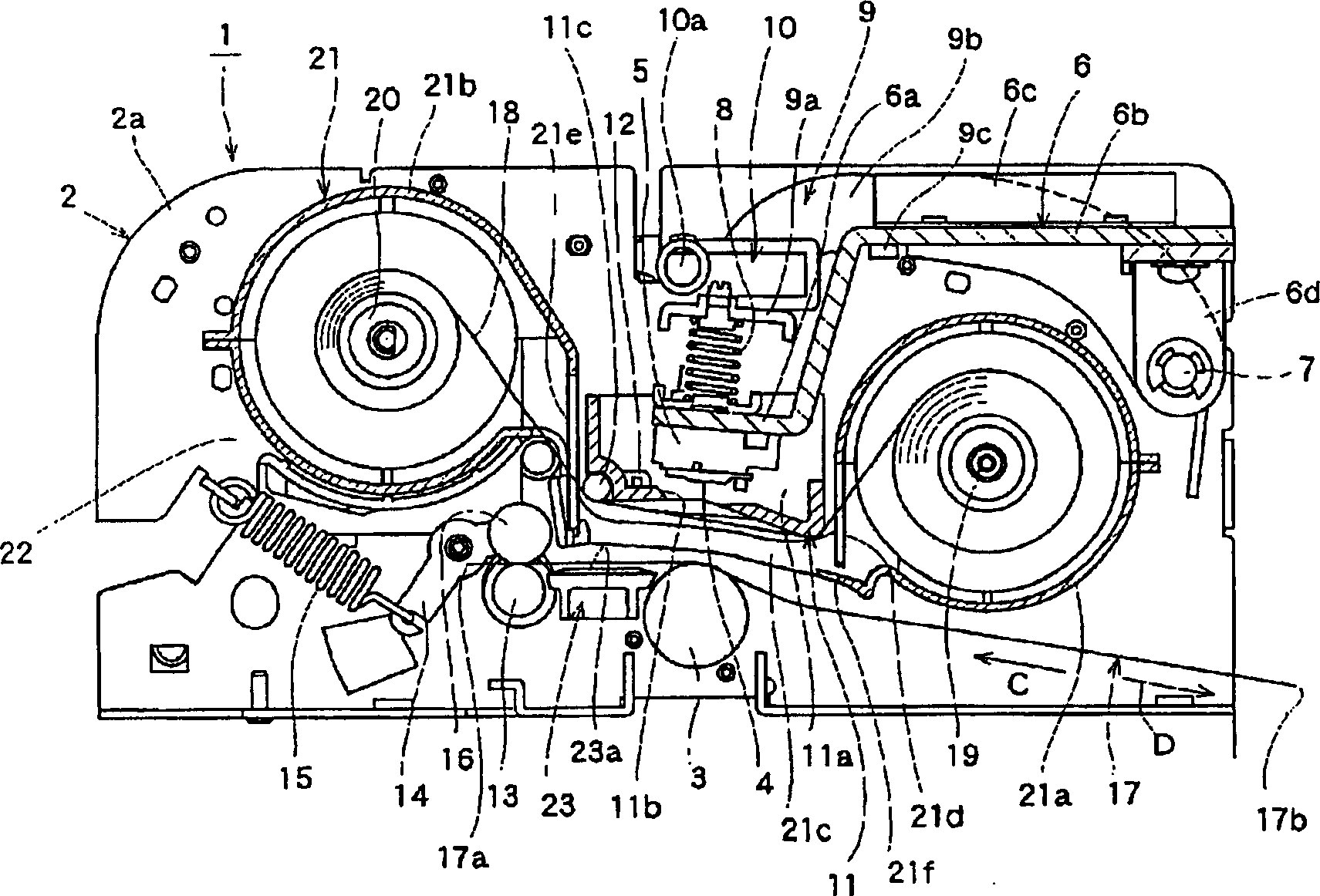

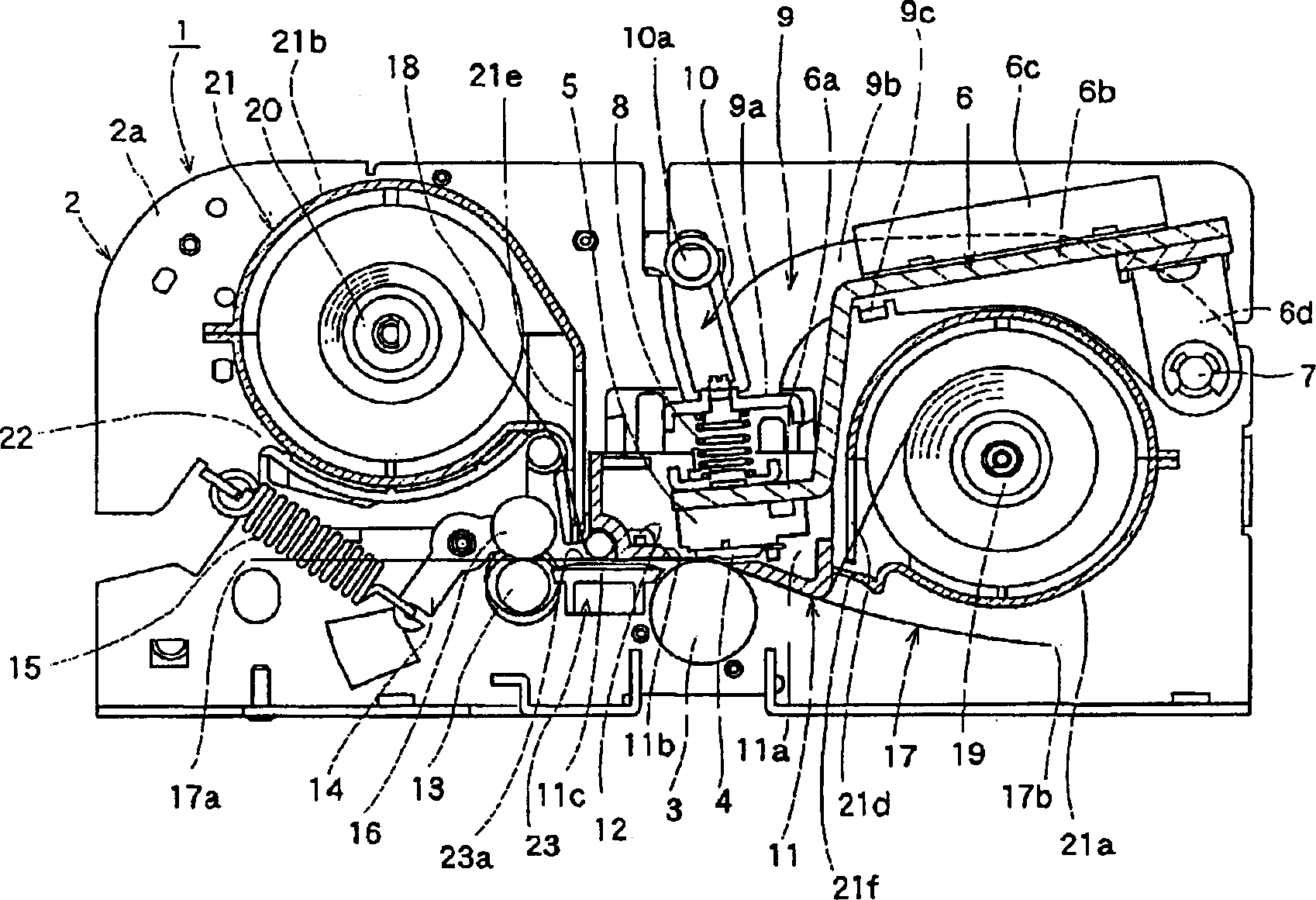

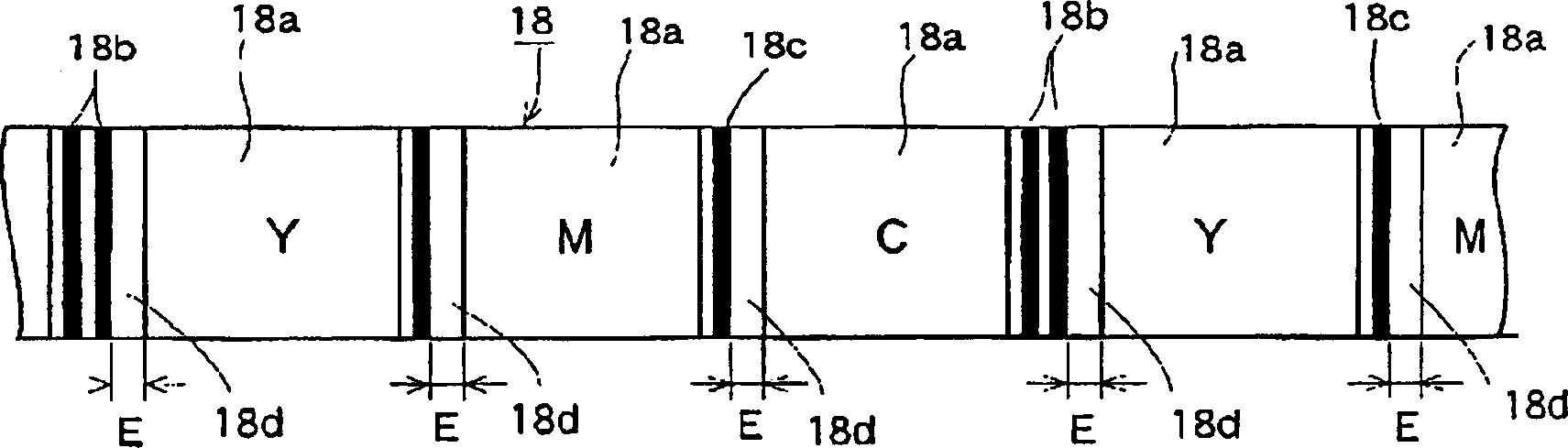

[0042] Below, with reference to the accompanying drawings, according to Figure 1 ~ Figure 3 One embodiment of the thermal transfer printer of the present invention will be described. figure 1 , figure 2 It is a sectional view of main parts of the thermal transfer printing machine of the present invention, image 3 It is a plan view of the ink ribbon of the present invention.

[0043] like figure 1 In the shown thermal transfer printing machine 1 , a cylindrical platen roller 3 , which is rotatably supported by a side plate 2 a of the main body cover 2 , is provided on the lower side.

[0044] A thermal head 4 composed of a long linear head parallel to the axial direction of the platen roller 3 is provided above the platen roller 3 .

[0045] The thermal head 4 has a plurality of heating elements (not shown) aligned and aligned in the longitudinal direction on the side opposite to the platen roller 3 , and is mounted on the head support member 6 through the head mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com