Non-circular gear epicyclic train shell-rotating hydraulic motor

A technology of hydraulic motor and non-circular gear is applied in the field of planetary gear type hydraulic power actuator, which can solve the problems of unreasonable motor structure design, complicated motor structure, increase of transmission chain, etc., and achieves simple manufacturing process, low cost, and improved reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

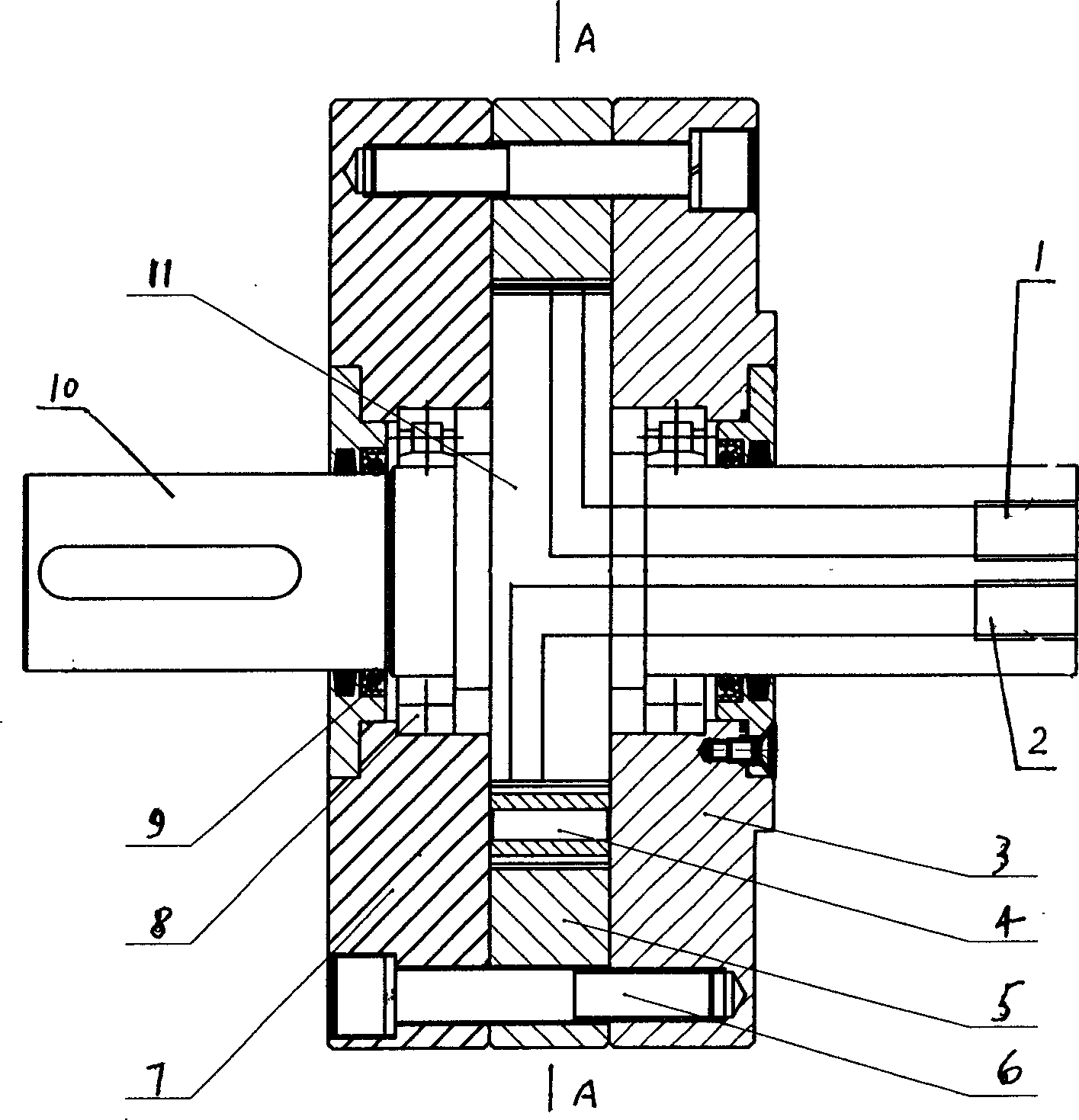

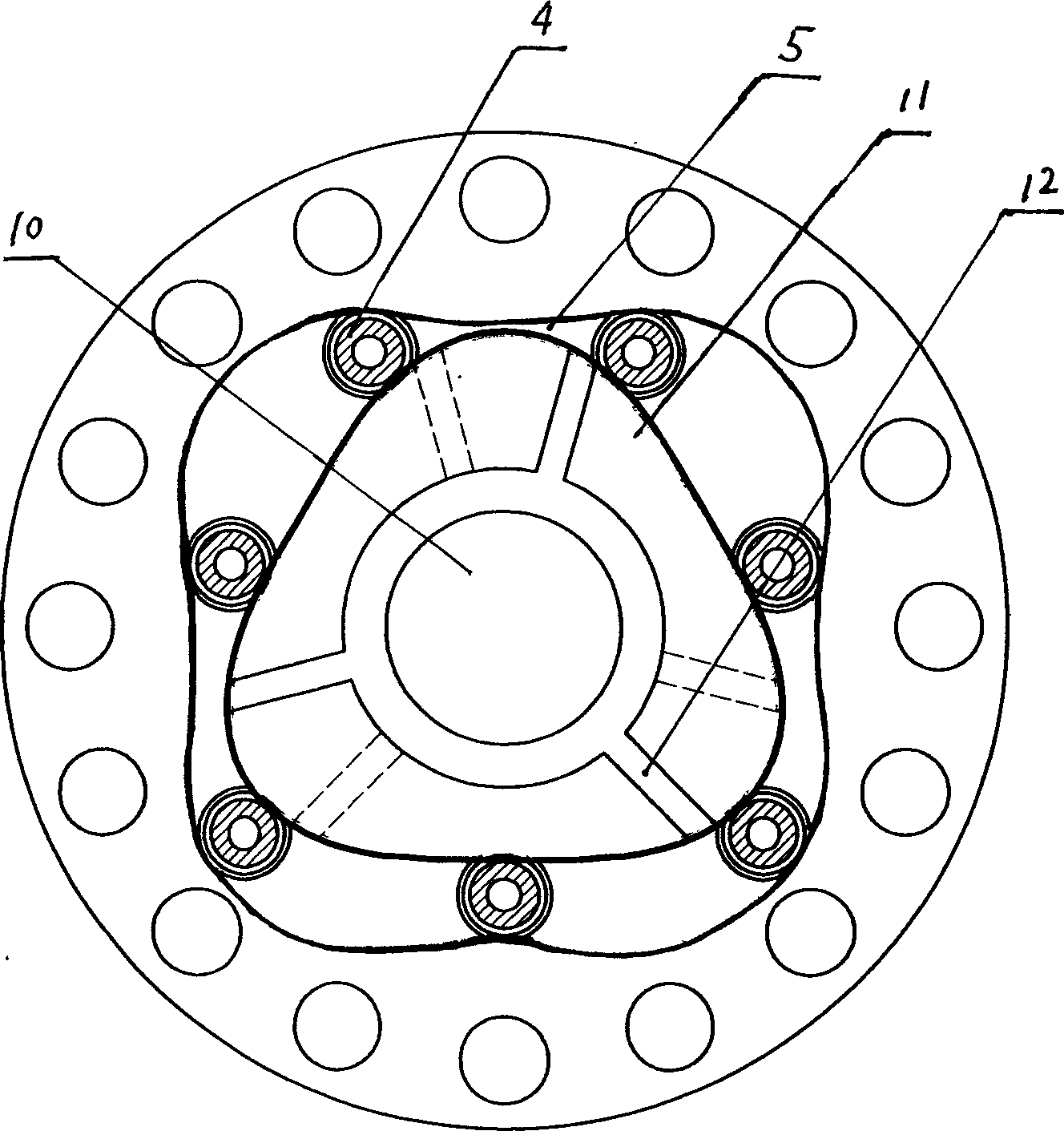

[0016] Such as figure 1 , figure 2 As shown, the shell-rotating hydraulic motor of the present invention includes a mandrel 10, a heart wheel 11 sleeved on the mandrel 10, a peripheral wheel 5 and a non-circular gear train composed of 7 planetary gears. There is an oil inlet 1 on the mandrel 11. , oil outlet 2, also have front body 3, rear body 7, sealing ring 9, bearing 8, front and rear body 3,7 to be fastened and connected by screw 6 in addition. The number of the periphery of the heart wheel is three, the number of the periphery of the peripheral wheel is four, the triangular heart wheel 11, and the quadrilateral peripheral wheel 5 are formed as figure 2 The knot curves shown are unique. Six flow distribution holes 12 are opened on the heart wheel 11 and distributed symmetrically, the number of which is twice the number around the heart wheel 11 . The heart wheel 11 is fixedly connected with the mandrel 10 , and the hydraulic oil enters the heart wheel 11 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com