Method and heating furnace for controlling product temperature evenness in metallurgical heating furnace

A heating furnace and uniformity technology, applied in the field of temperature uniformity control, can solve problems such as unfavorable and unfavorable burner good efficiency, and achieve the effect of improving temperature uniformity and reducing the existence of hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

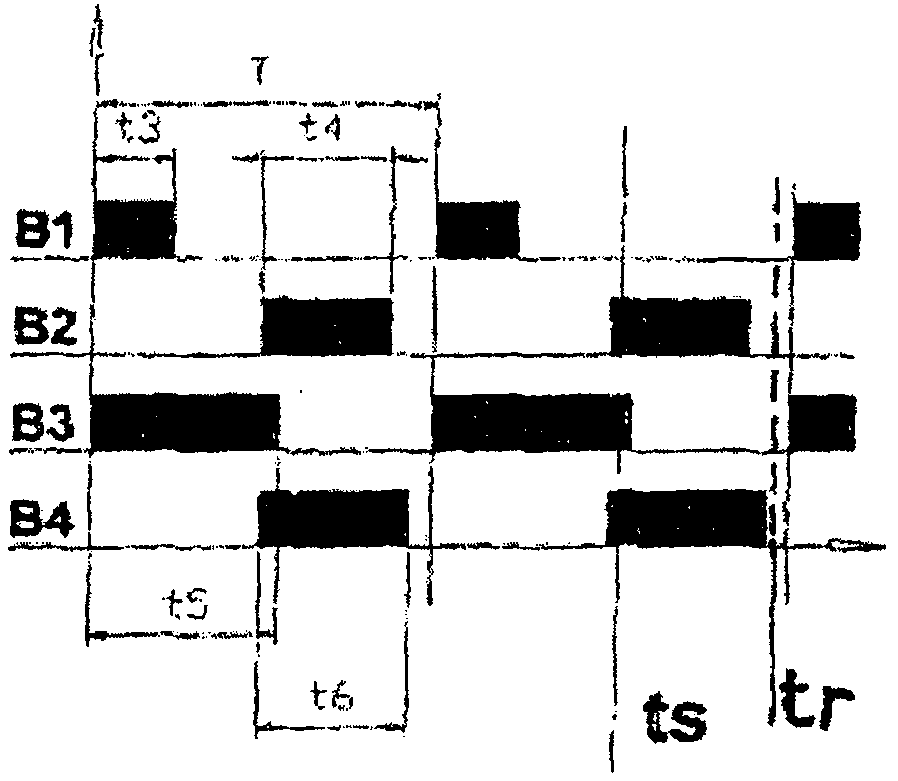

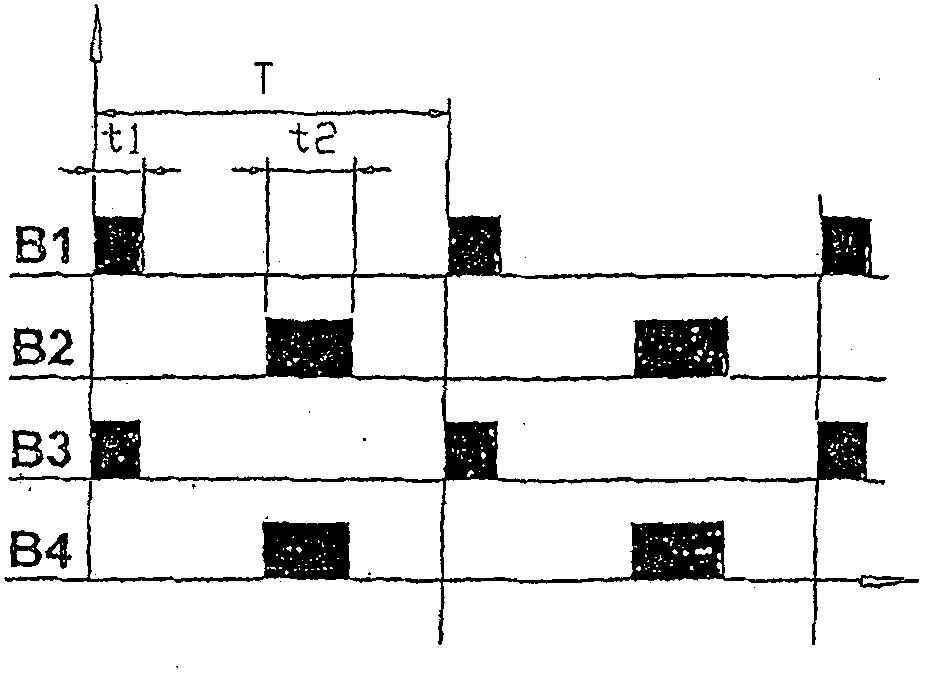

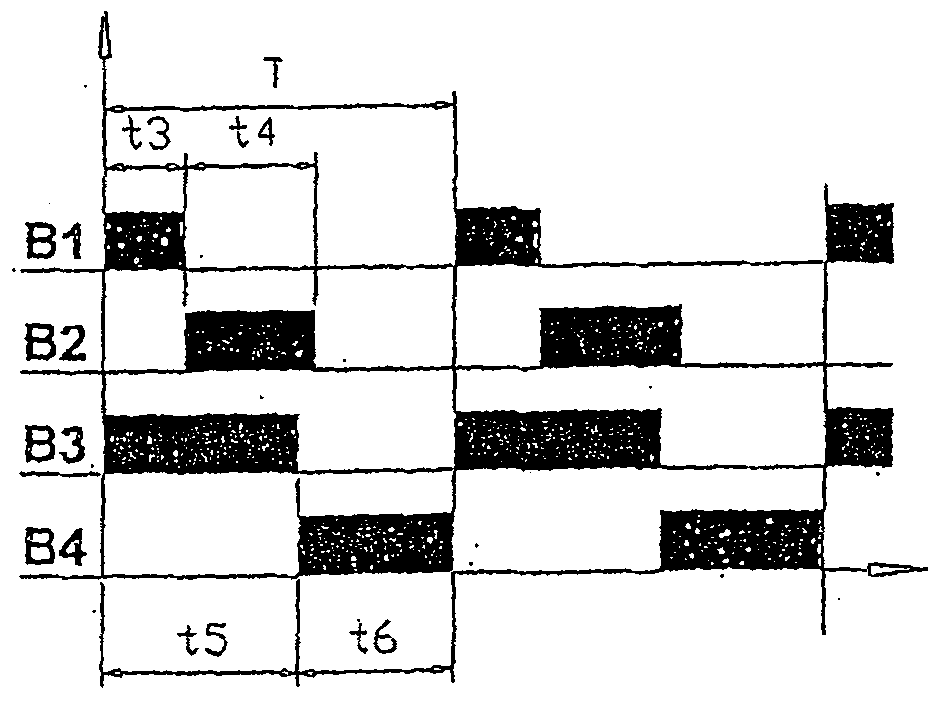

[0039] Referring to FIG. 1 , a heating furnace consisting of an insulated furnace chamber 1 can be seen schematically. A product 2 to be heated is supported in the heating furnace by a support beam 3 and moved from right to left in the figure by a mechanism 4 . Spread flame burners 5 are located on the side walls of the furnace above and below the product 2 bed.

[0040] Figure 2 schematically shows a spread-flame burner provided with a combustion channel 6 of widened (élargie) shape, L at least equal to 1.3 times H, and having some long axis of symmetry PS with the channel and located in the furnace The plane P of the product is parallel to the fuel injection nozzle 8 and the oxidizer nozzle 7 . The direction of the fuel and oxidant injection nozzles is chosen so as to produce a poor distribution of combustion products and circulating flue gases in order to obtain a spreading flame that ensures a uniform distribution of heat flux.

[0041]An example of a furnace according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com