Rotary magnetic rheological brake

A brake and magneto-rheological technology, applied in the direction of brake types, liquid resistance brakes, mechanical equipment, etc., can solve the problems of complex control mechanism, insufficient control torque, low manufacturing cost, etc., to solve the difficulty of magnetic circuit layout and simplify the control structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

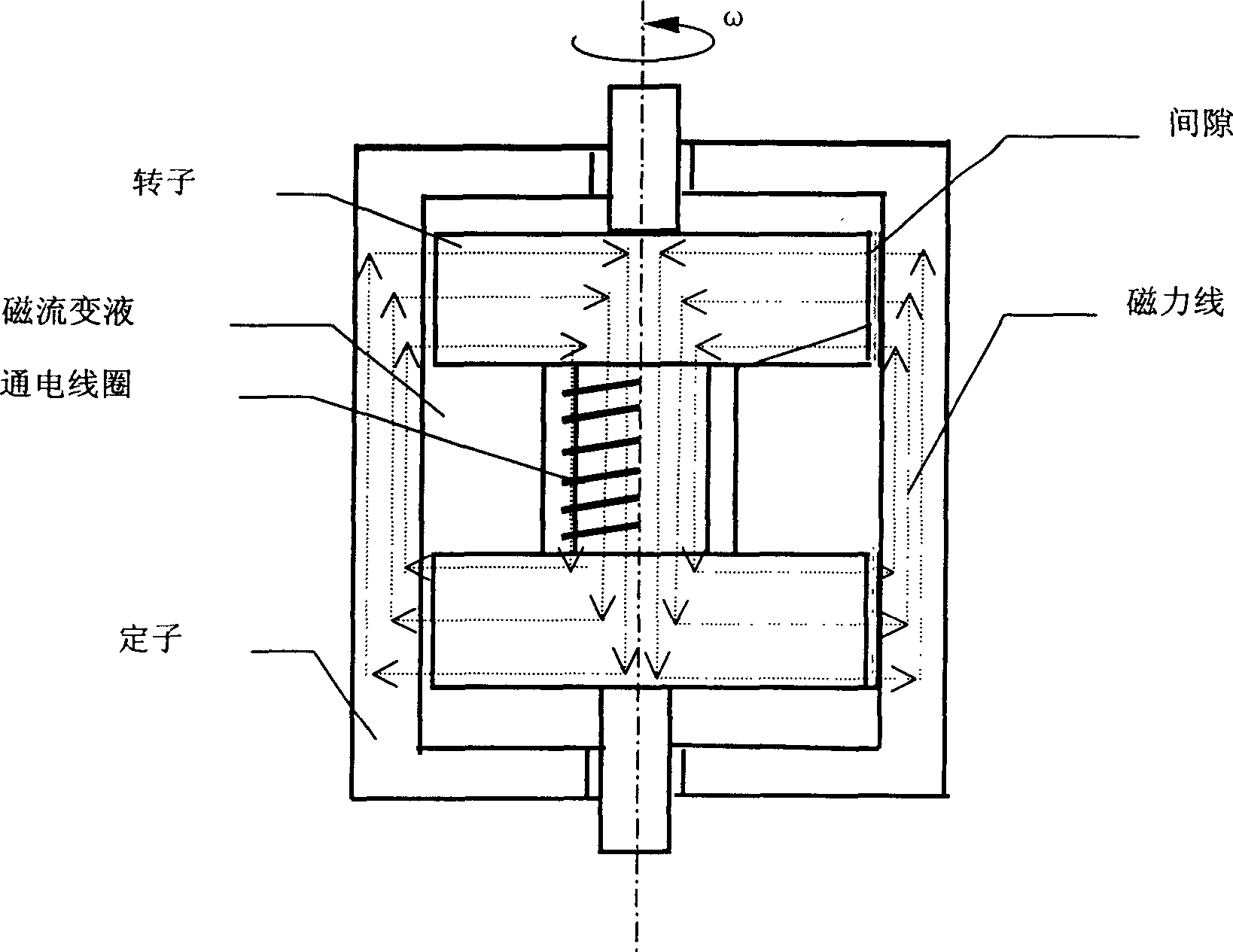

[0008] The present invention is achieved through the following technical solutions:

[0009] 1. Structural design: The entire slewing brake is divided into three parts: rotor, stator and magnetorheological fluid between the rotor and stator. The stator is the housing of the brake and is stationary. The rotor is a part that conducts rotary motion. There are round tables at both ends of the rotor, which are integrated with the rotating shaft in the middle; the middle is divided into two layers: the inner and outer layers. The rotor and stator should be made of high magnetic permeability metal materials.

[0010] The gap between the circular platform on the rotor and the stator is far smaller than the radius of the circular platform and the axial length of the circular platform, and the gap between the circular platform on the rotor and the stator and the space between the plastic part and the stator are filled with magnetorheological fluid.

[0011] 2. The design of the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com