Defoaming agent composition for oil in water type emulsion

An oil-in-water emulsion and defoamer technology, applied in the directions of liquid degassing, foam dispersion/prevention, chemical instruments and methods, etc., can solve problems such as insufficient viscosity stability, and achieve excellent defoaming effect and good time stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

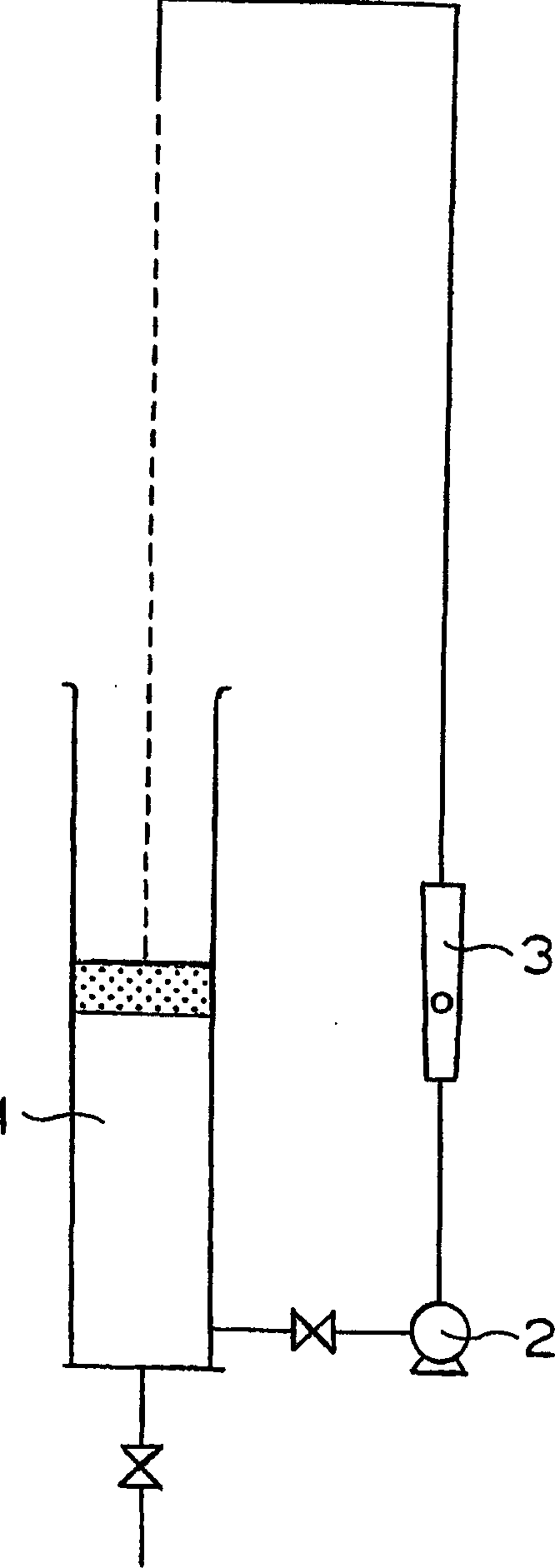

Image

Examples

Embodiment 1

[0045] 20 parts by weight of C18-22 fatty alcohol (manufactured by SASOL Corporation, phenenol 1822), 4 parts by weight of solid paraffin (manufactured by KANTO Chemical Co., Ltd., melting point: 68-70° C.), 6 parts by weight of glycerin oleate Tryester (manufactured by Fuji Petroleum Co., Ltd., Highol) and primary alcohol liquid solution of branched chain alkyl with about 11 carbon atoms (made by Kao company; EMULGEN 1135S-70, HLB: 17.9; concentration: 70% by weight) were mixed together and melted to form a mixture. When the molten mixture was stirred at 73° C. with a turbine blade at a peripheral speed of 5.2 m / s, 68.5 parts by weight of water heated to 73° C. was added, and a phase change was performed by emulsification. After adding 0.1 part by weight of wellan gum (Sansho Corporation; K1 containing C376), the resulting mixture was cooled from 73°C to 30°C over 18 hours to obtain an oil-in-water emulsion defoamer composition.

[0046] In the defoaming test, the amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

PROBLEM TO BE SOLVED: To provide an oil-in-water type emulsion defoaming agent composition having an excellent defoaming effect, having excellent storage stability with respect to compounding which can not ensure sufficient storage stability even if an ethylene oxide adduct of a secondary alcohol as an emulsifier is used and not almost thickened during storage.

SOLUTION: The oil-in-water type emulsion defoaming agent composition contains (A) an oil phase component containing a 12-30C higher aliphatic alcohol and (B) a 2-4C alkylene oxide adduct of a primary alcohol having a branched alkyl group.

COPYRIGHT: (C)2006,JPO&NCIPI

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap