Ligh guide plate and back ligth module using said light guide plate

A backlight module and light guide plate technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of display quality degradation, complex backlight module design, and light guide plate design, and achieve the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

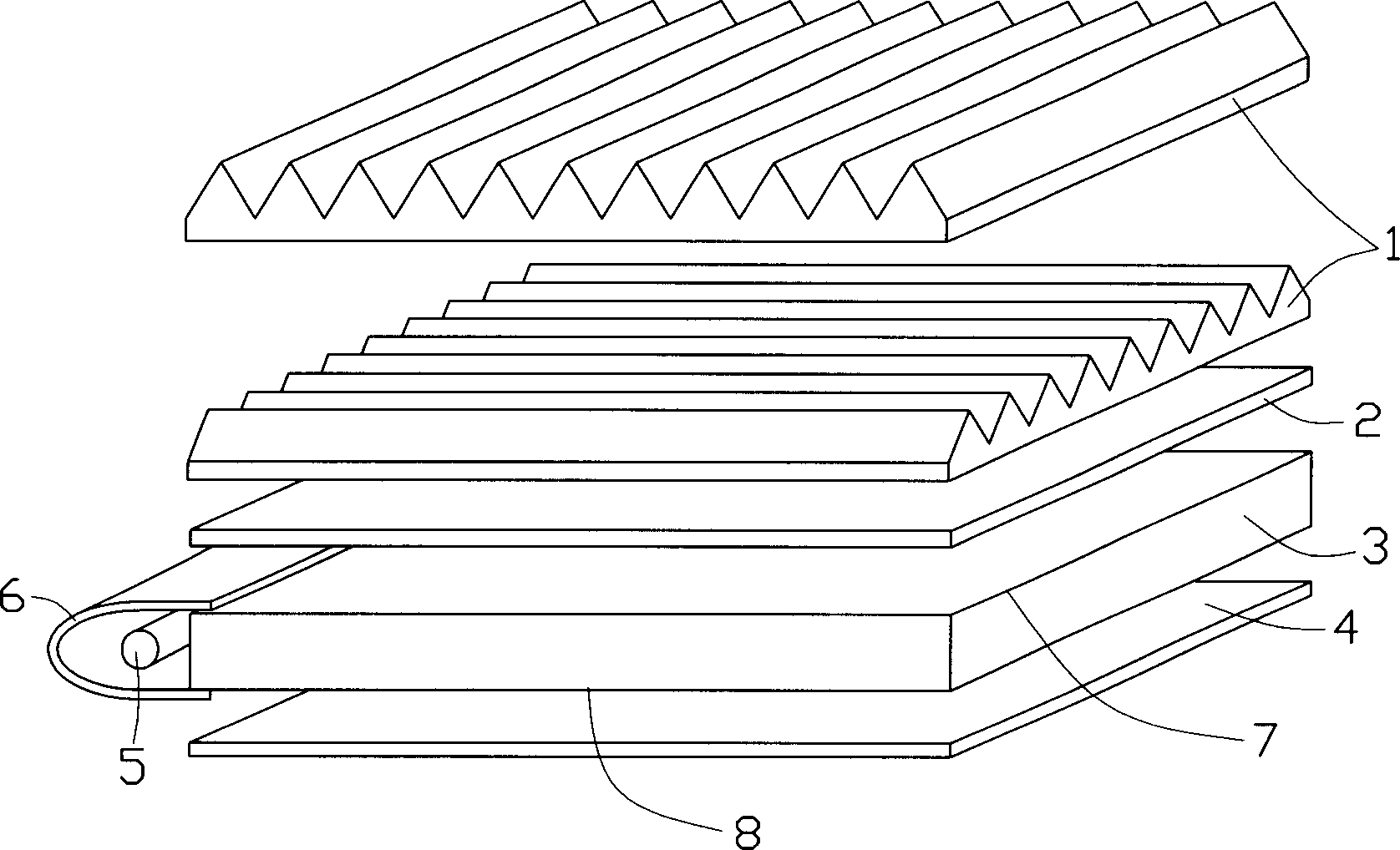

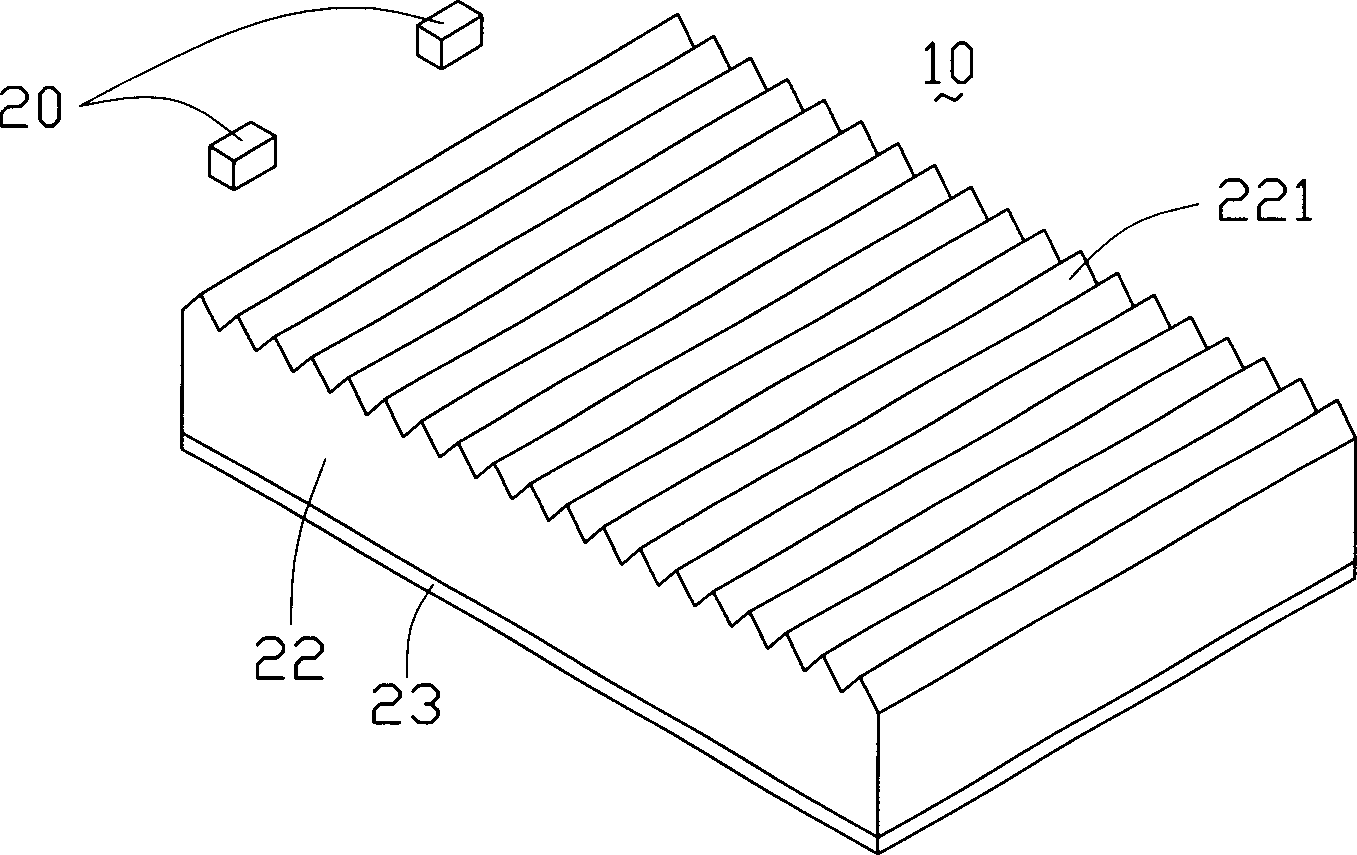

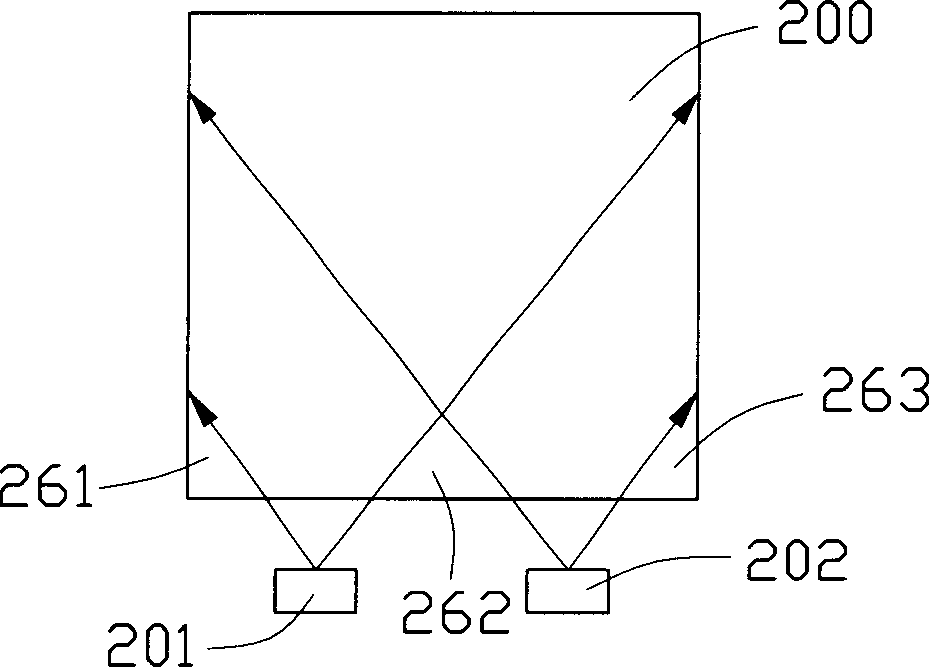

[0020] Please refer to Figure 4 to Figure 5 , is a schematic perspective view of the first embodiment of the backlight module of the present invention and its top view. The backlight module 40 includes a light guide plate 49 and a light source 43 .

[0021] The light guide plate 49 includes a display area 42 and a redundant area 41 adjacent to the display area 42. The display area 42 and the redundant area 41 are integrally injection-molded, both of which are parallelepiped structures, and are made of transparent polymer resin or glass. The display area 42 corresponds to the main display area of the display panel (not shown). The redundant area 41 is located at one end of the light guide plate 49 adjacent to the light source 43, and includes a light incident surface 48 and a light exit surface 47 adjacent to the light incident surface 48, and an auxiliary display area is provided on the light exit surface 47 411. The auxiliary display area 411 corresponds to the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com