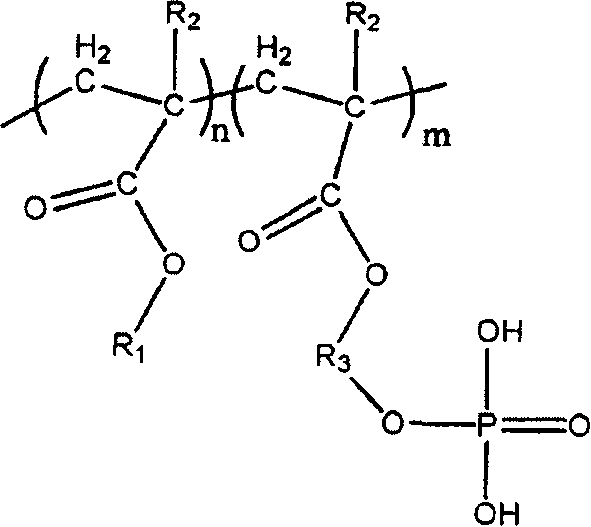

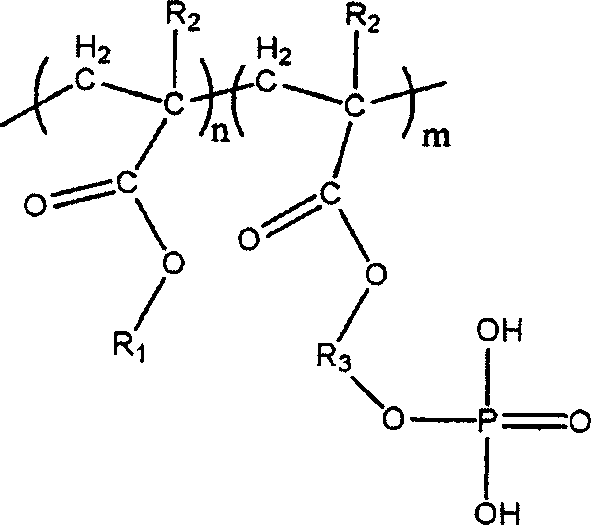

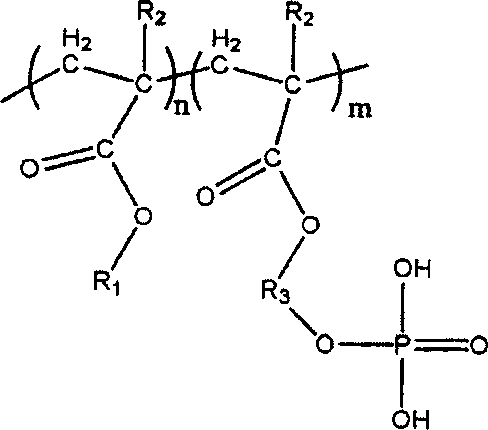

Photosensitive resin composition and dry film resist using the same

A technology of photosensitive resin and composition, which is applied in the field of dry film resist and alkali-soluble photosensitive resin composition, can solve the problems of destroying the storage stability of the composition, instability of the viscosity enhancer, etc., achieve excellent storage stability, improve High effect of adhesion, heat resistance and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

[0043] (Preparation of polymer resin)

[0044] According to the components and contents shown in Table 1 below, acrylate copolymer resins represented by Chemical Formula 1 (Preparation Examples 1 and 2), and conventionally used acrylate copolymer resins (Comparative Preparation Examples 1 and 2) were prepared. ). 70 wt% tetrahydrofuran (TFH) was used as a polymerization solvent. Polymerization was performed at 45°C using a low temperature initiator.

[0045] Classification

[0046] In Table 1, BM stands for benzyl methacrylate; MA stands for methacrylic acid; PAM-100 and PAM-200 are phosphate-containing methacrylates prepared by RHODIA; HEMA stands for 2-hydroxyethyl methacrylate ester; and MMA stands for methyl methacrylate.

Embodiment 1~5 and comparative Embodiment 1~3

[0048] (Preparation of Photosensitive Resin Composition)

[0049] The cross-linking monomer, photopolymerization initiator, dye and colorant were added to the acrylate copolymer resin, and Table 2 below shows the respective compositions and contents. After the components were dissolved, the mixture was stirred at room temperature for 2 hours, thereby obtaining a photosensitive resin composition. The resulting photosensitive resin composition was filtered with a 500-mesh filter, thereby removing impurities.

[0050] Classification (wt%)

Example

comparative example

1

2

3

4

5

1

2

3

Tree

fat

Preparation Example 1

30

-

32

-

15

-

-

-

Preparation Example 2

-

30

-

32

15

-

-

-

Comparative Preparation Example 1

-

-

-

-

-

30

- ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com