Torch combined with low pressure head by burning buried gas

A technology for landfill gas and landfill gas, applied in burners, incinerators, combustion methods, etc., can solve problems such as air pressure fluctuations and large changes in landfill gas load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but it should be pointed out that the following words are only for illustration, rather than limitation.

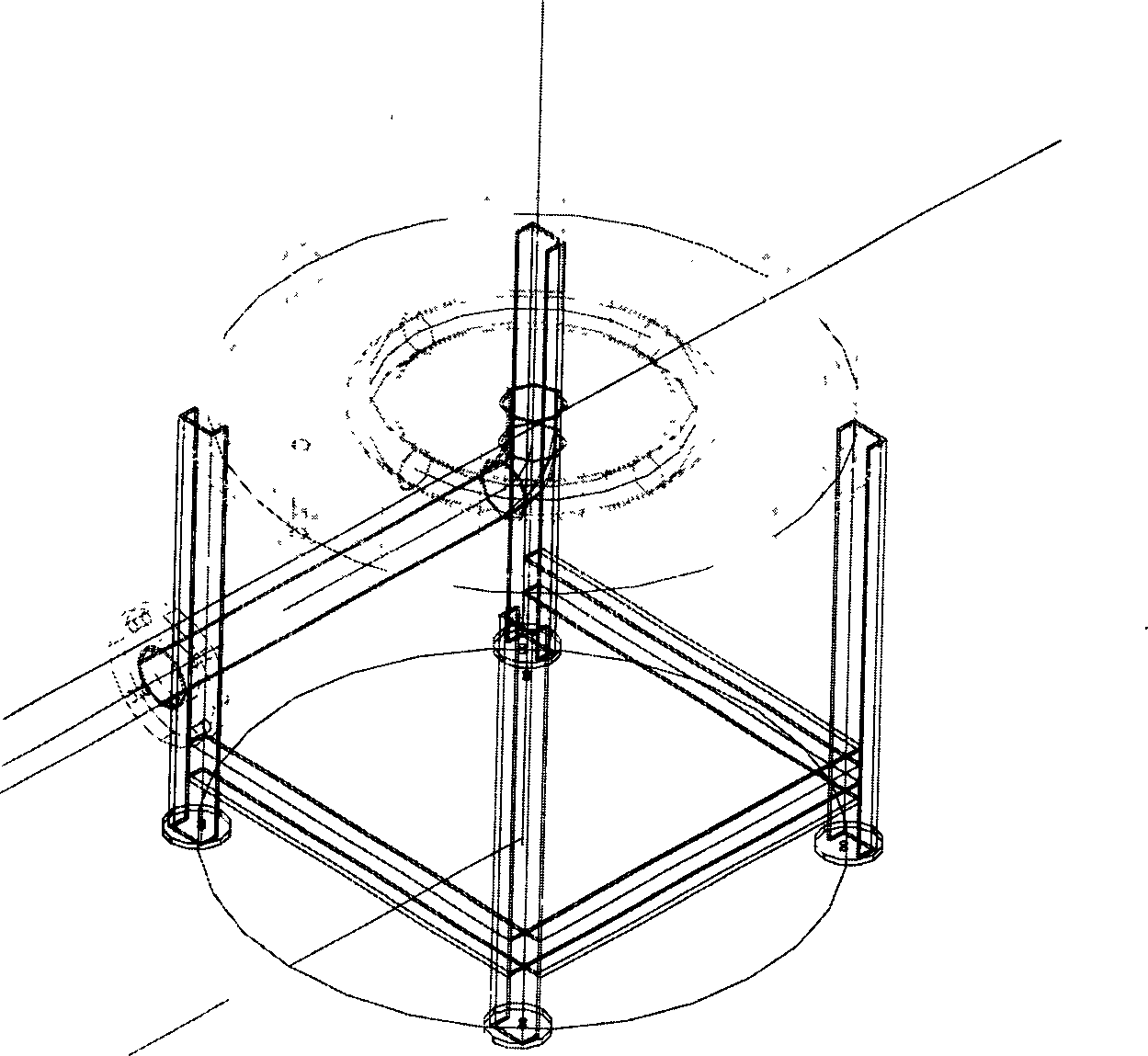

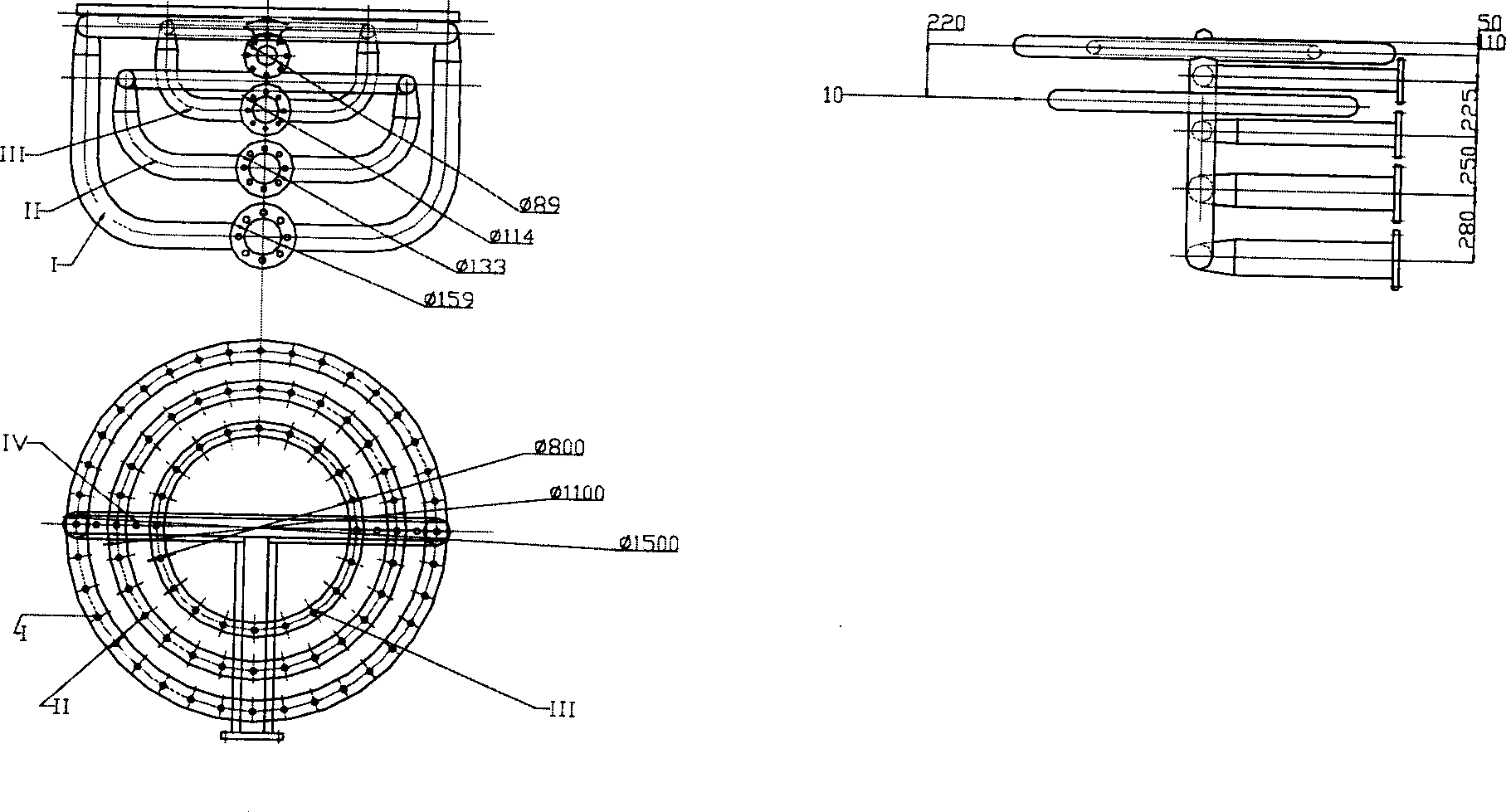

[0023] exist figure 1 Among them, different numbers of burners form burner groups arranged in a ring, and the number of groups can be selected according to different landfill gas volumes. figure 1 Two sets of annular burner stacks are shown in , four brackets support the burner stacks with different diameters, and a pipe carries landfill gas to the burner stacks for combustion.

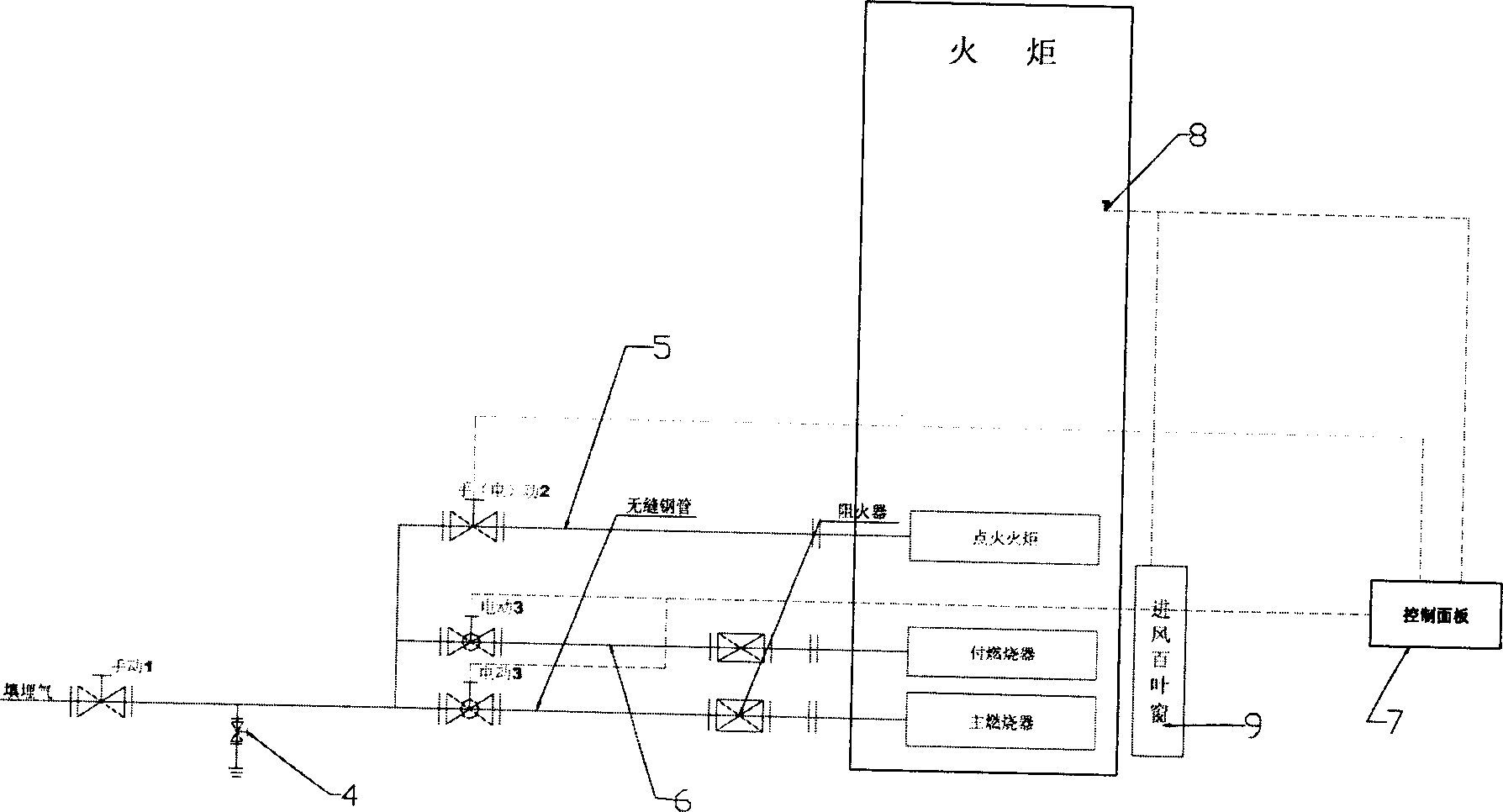

[0024] figure 2 Among them, the landfill gas from the landfill gas main pipe of the waste landfill first passes through the manual valve 1 (the sewage valve 4 is installed on the main pipe), and then enters the flare tower through the branch pipe composed of three seamless steel pipes; the three branch pipes are respectively It is connected with the ignition torch, the main burner and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com