Slag-removing pot cleaning machine for metallurgy furnace

A metallurgical furnace and component technology, applied in the field of metallurgical furnace slag removal device, can solve the problems of surrounding environmental pollution, reduce the effective volume of slag pot, etc., and achieve the effects of improving work efficiency, shortening time for slag dumping, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the metallurgical furnace slag cleaning machine will be described in detail below in conjunction with the examples, but the specific implementation of the metallurgical furnace slag cleaning machine is not limited to the following examples.

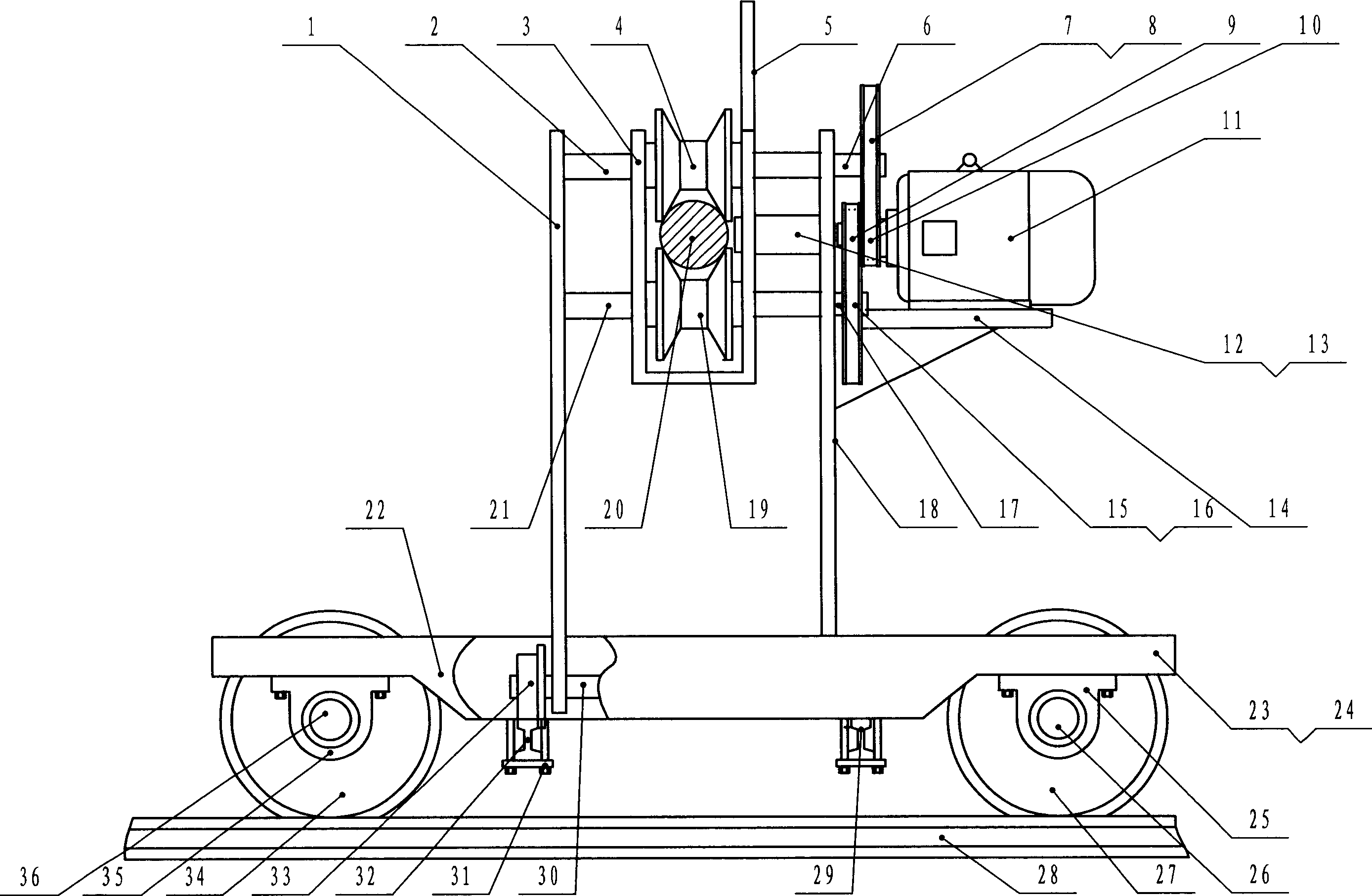

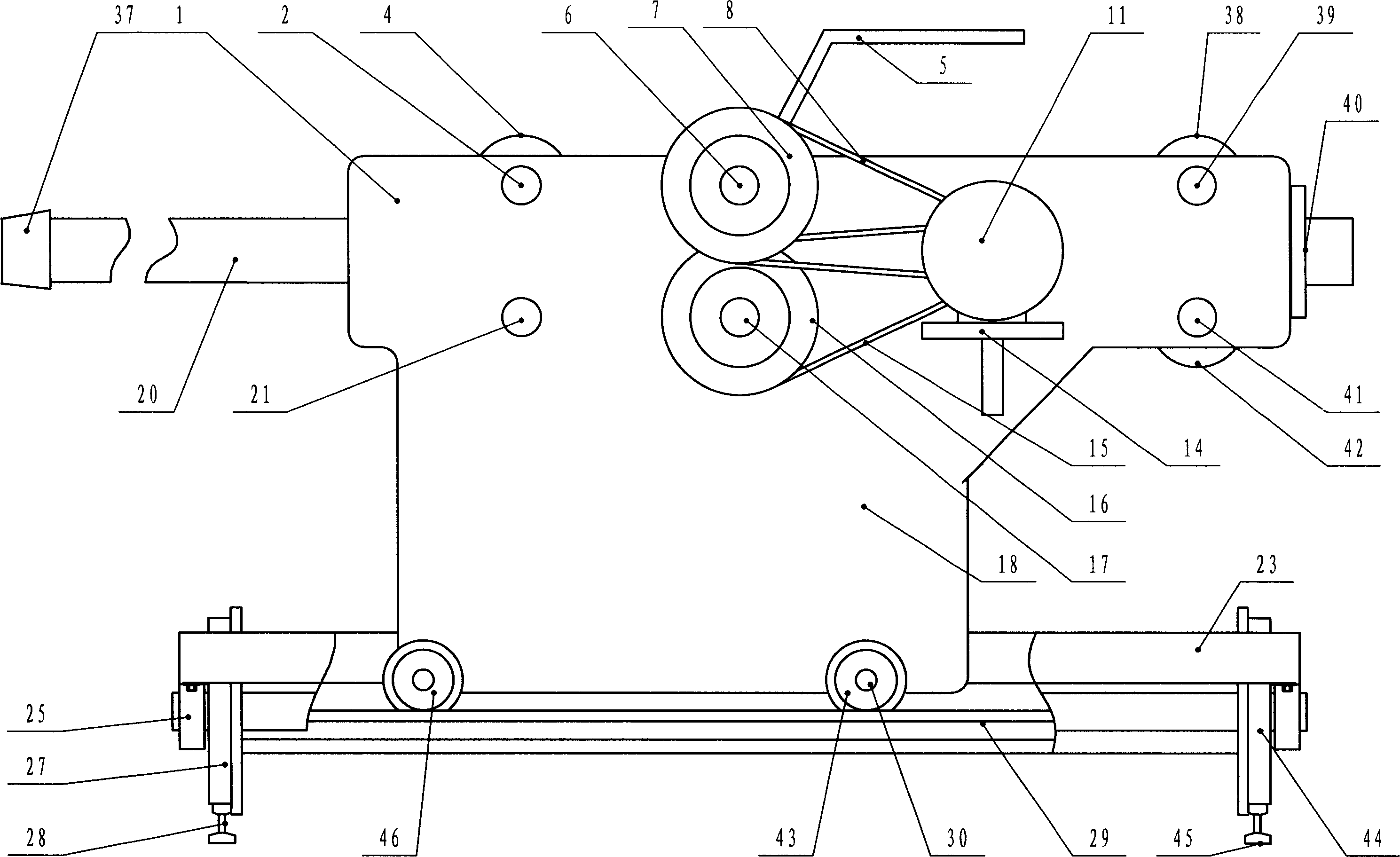

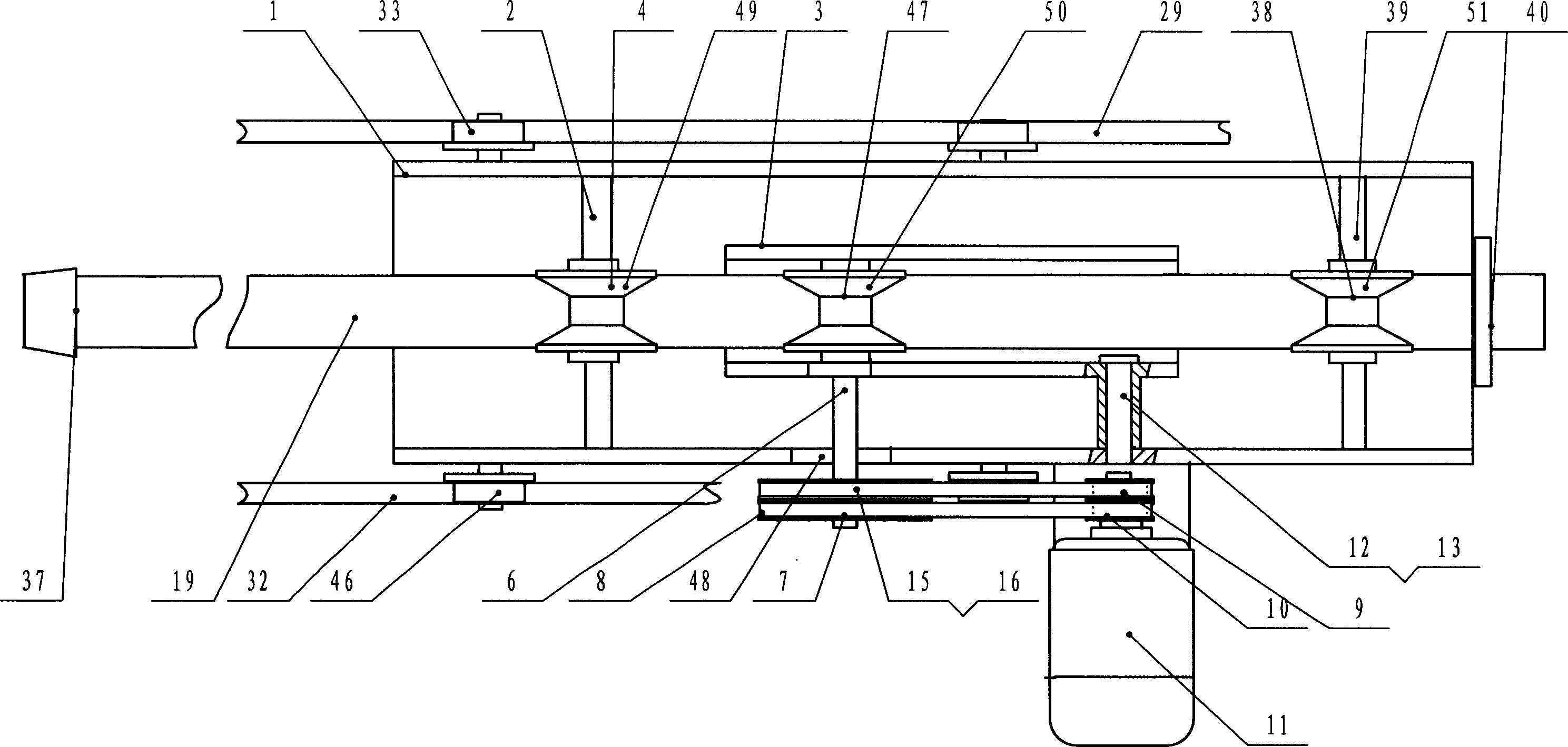

[0028] figure 1 , figure 2 and image 3 The described metallurgical furnace slag cleaning machine includes a pounding element and a pounding element driving device, and the pounding element is installed on the pounding element driving device, and it is characterized in that: said pounding element is a pounding lever 20, and the Said pounding pot element driving device is a potting car, and the potting car has a bottom car 22 that moves on the ground rail and a main car 1 that moves on the bottom car 22, and the bottom car 22 has a frame-shaped vehicle frame 23. Shaped vehicle frame 23 is equipped with four iron wheels, and the width of two relative iron wheels matches with two rails on the ground, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com