Backlight module structure

A technology of backlight module and light-emitting surface, applied in optics, nonlinear optics, instruments, etc., can solve the problems of inability to effectively use the limited space of products, weaken the light intensity of light-emitting diodes, increase production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

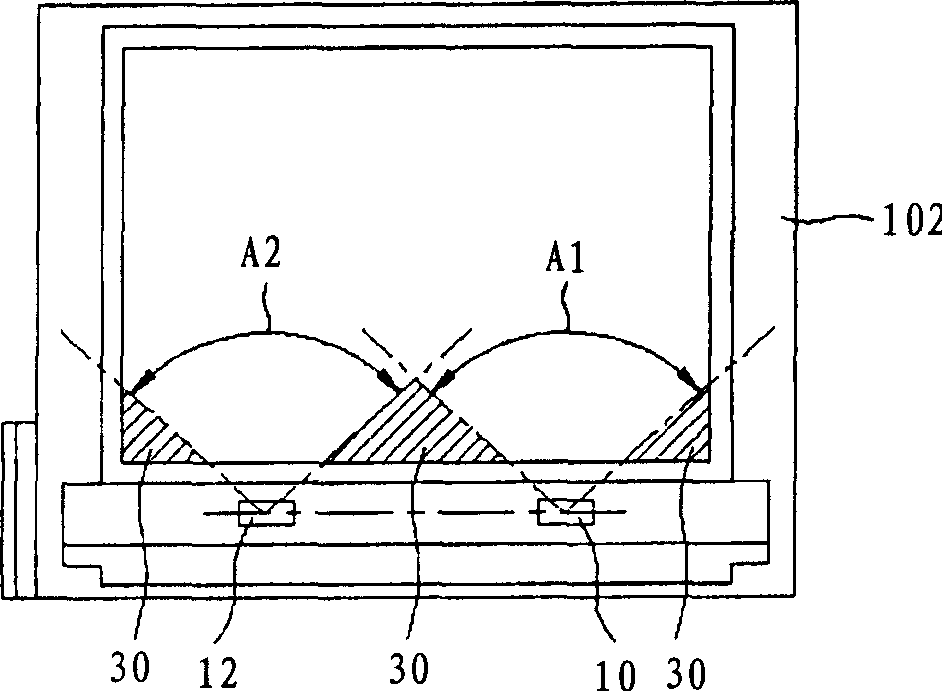

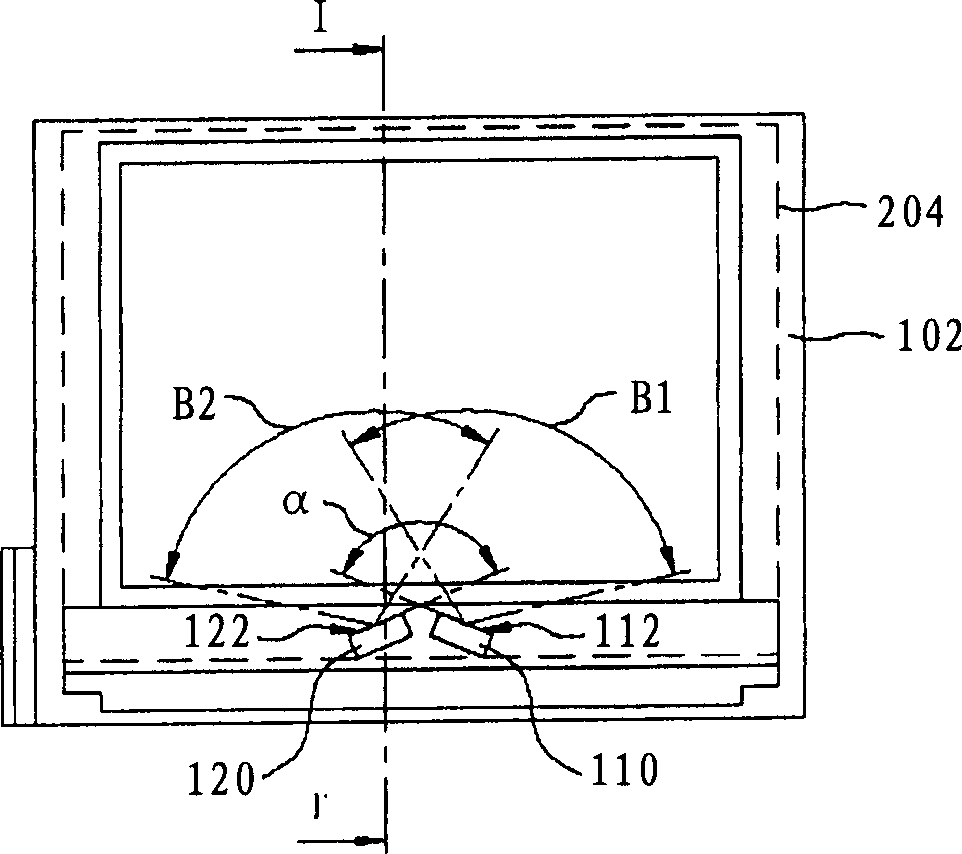

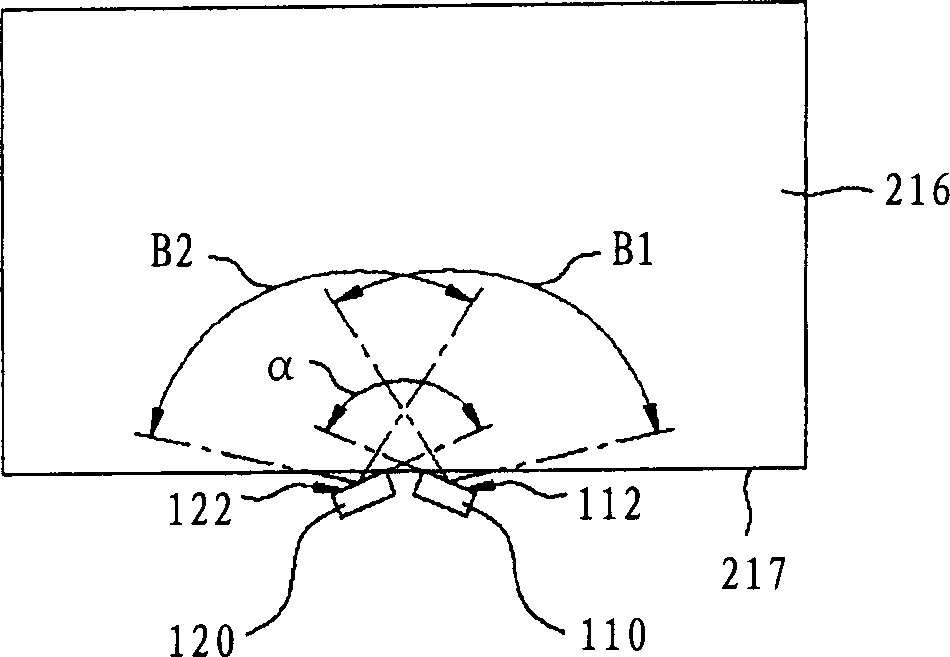

[0032] In the backlight module structure of the present invention, two adjacent light-emitting diodes are adjacently arranged on the light guide plate, and the light-emitting surface of each light-emitting diode is inclined outward at a preset angle, wherein the two light-emitting surfaces of the two light-emitting diodes extend out The outside angle is between about 90 degrees and 180 degrees.

[0033] Please refer to Figure 2A with Figure 2B , Figure 2A is a schematic diagram illustrating a liquid crystal display according to a preferred embodiment of the present invention; Figure 2B It is a schematic diagram illustrating the structure of an LED backlight module according to a preferred embodiment of the present invention.

[0034] Such as Figure 2A As shown, the liquid crystal display of the present invention includes a rectangular frame body 102 with four connected sides, a liquid crystal panel 204 and a backlight module structure (not shown), wherein the backligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com