Aqueous silylated urethane composition, aqueous adhesives for wrapping, and aqueous contact adhesives

A water-based composition, polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of not being able to say very sufficient, limited application scope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

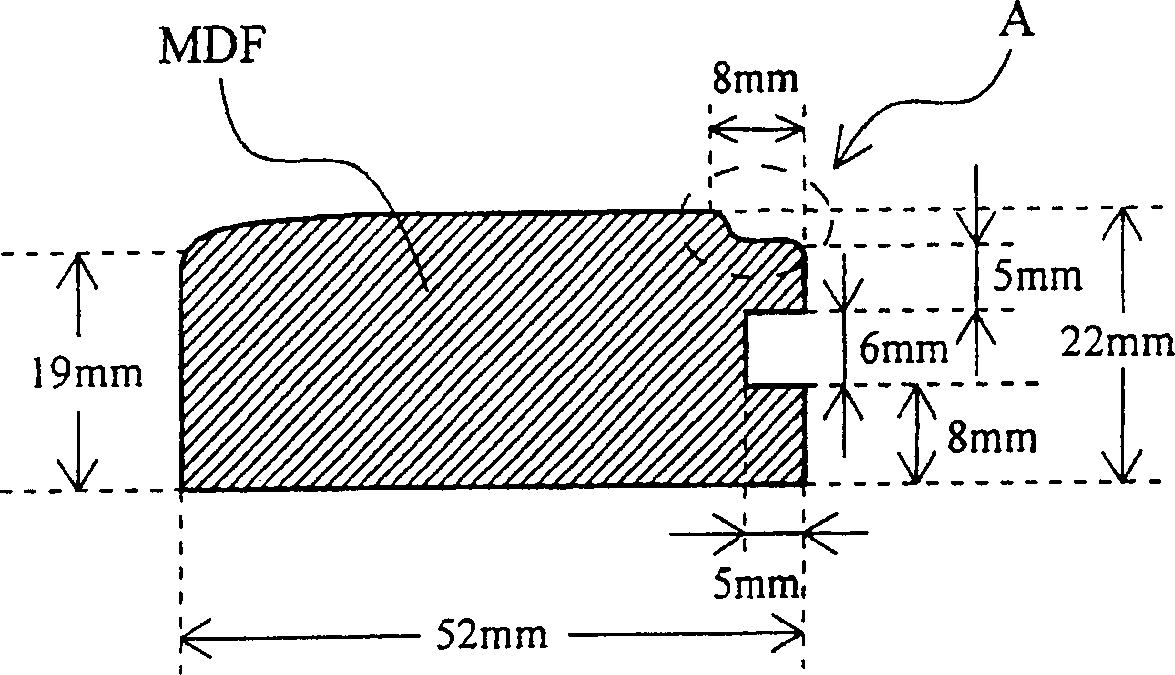

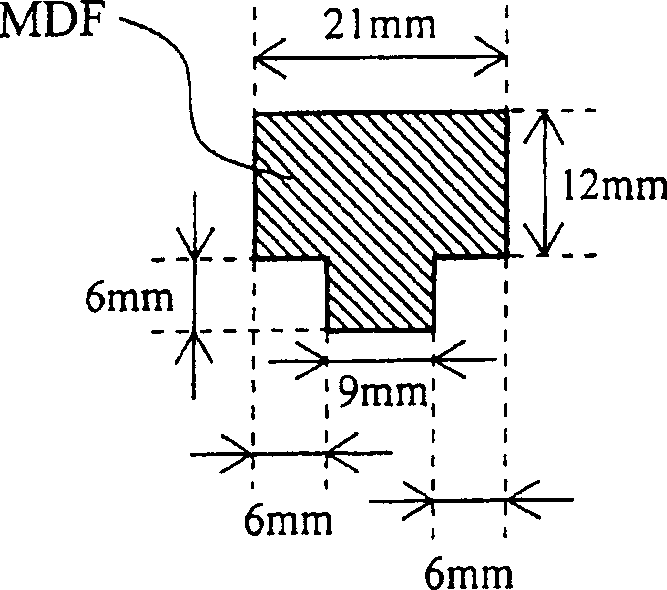

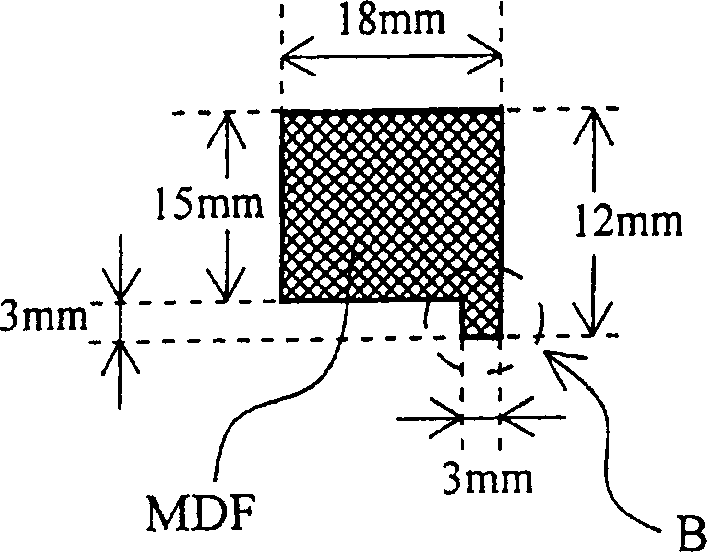

Image

Examples

Embodiment 1

[0216] Mix polyol (A1-a): 150 parts, polyol (A2-b): 20 parts, polyol (A3-a) in a 4-neck flask equipped with a nitrogen inlet tube, thermometer, condenser, and stirring device : 8 parts, polyisocyanate (A4-a): 75.2 parts and methyl ethyl ketone (MEK): 100 parts, carried out the reaction for 6 hours at a temperature of 80 to 85° C. under a nitrogen stream to obtain a carboxyl group-containing and Reaction mixture of isocyanate-terminated polyurethane prepolymers with tertiary amino groups.

[0217] Next, in the total amount of the reaction mixture of the isocyanate group-terminated polyurethane prepolymer containing carboxyl groups and tertiary amino groups, 6.5 parts of alkoxysilanes (A5-a) containing amino groups: The reaction was carried out under temperature and nitrogen flow for 1 hour to obtain a reaction mixture containing isocyanate groups containing carboxyl groups and tertiary amino groups and alkoxysilyl-terminated polyurethane prepolymers.

[0218] Furthermore, afte...

Embodiment 2~13

[0220] Except having made the composition shown in Table 1 or 2, it carried out similarly to Example 1, and obtained the silylated polyurethane type aqueous composition which concerns on Examples 2-13, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com