Method for testing flax/cotton blending ratio

A test method, cotton blending technology, applied in the preparation of test samples, color/spectral characteristic measurement, special data processing applications, etc., can solve the problems of being easily affected by subjective factors, ignoring the cavity structure of fibers, eye fatigue, etc. , to achieve the effect of avoiding low professional technical level and proficiency, strong representativeness, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

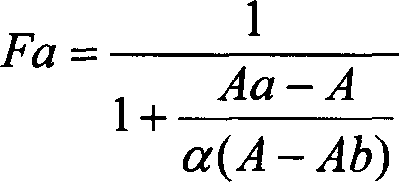

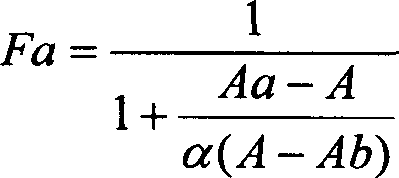

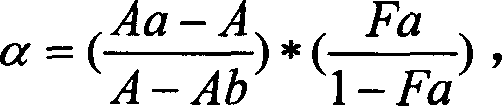

[0026] The present invention is based on Raspberry's theory that "when binary substances are dissolved in the same solution, there is a certain relationship between their concentrations", the dissolved concentration of hemp and cotton fiber in the same solution should be certain, which also conforms to Raspberry's theory . The absorbance value of the hemp cotton fiber solution should also conform to Rasbury's formula.

[0027] A kind of test method of hemp / cotton blend ratio, concrete test steps are as follows:

[0028] (1) Select the hemp and cotton varieties of the hemp / cotton mixture that need to measure the blending ratio, test the absorbance value Aa of the cotton fiber solution, the absorbance value Ab of the hemp fiber solution, and the known mixing ratio of the hemp / cotton mixture that is Fa. The absorbance value A of the liquid, the absorbance value Aa, Ab of cotton and hemp and the absorbance value A of the hemp / cotton mixture with known mixing ratio are brought int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com