Thermoplastic elastomer and molded product produced from the same

A thermoplastic elastomer, modified technology, applied in the direction of coating, etc., can solve the problems that cannot be said to be improved sufficiently, and achieve the effects of excellent dry touch, no sticky feeling, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

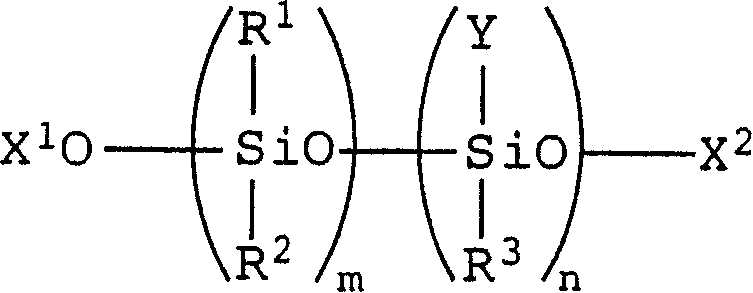

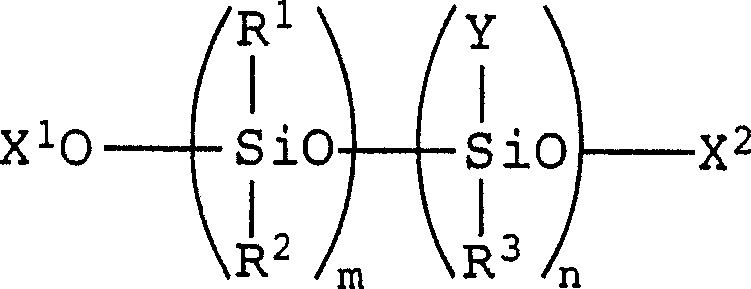

Method used

Image

Examples

Embodiment

[0129] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to the following Example unless the summary is exceeded. The materials and evaluation methods used in the following examples are as follows.

[0130]

[0131] In Examples 1 to 14 and Comparative Examples 1 to 4, 0.1 parts by weight of tetrakis[methylene-3-(3',5'-bis tert-butyl-4'-hydroxyphenyl) propionic acid] methane ("Irganox 1010" produced by Ciba Specialty Chemicals Co., Ltd.) was used as a stabilizer, mixed in a Henschel mixer, and supplied to the plastic using a gravimetric feeder. The twin-screw extruder "BT-30" (L / D = 30, rotating in the same direction) produced by the Engineering Research Institute was extruded at 210°C and the screw speed was 200rpm (dynamic heat treatment) to obtain a thermoplastic elastomer composition . The obtained thermoplastic elastomer was supplied to "CN-75" manufactured by Niigata Iron Works Co., Ltd., and injection-molded un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com