A kind of preparation method of fermented milk-containing carbonated beverage

A carbonated beverage, fermented technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of unimproved stability, harshness, and low acceptance of beverage precipitation, and achieves inhibition of aggregation and precipitation without stickiness. , the effect of refreshing flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

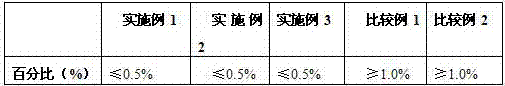

Embodiment 1

[0036] Take 6.25kg of skimmed milk powder, add 20kg of water, and dissolve at 40-50°C for about half an hour. Add 5kg of white sugar and fully dissolve it. 0.25kg of polydextrose is dissolved in 10kg of hot water, the temperature is controlled at 70-90°C, and sheared at 3000rpm for about half an hour. 0.10 kg of high acyl pectin was dissolved in 10 kg of hot water, the temperature was controlled at 70-90 °C, and sheared at 3000 rpm for about half an hour. After mixing, make up to 50 L. Then kill at 90°C for 5 minutes. Cool quickly to room temperature. Inoculate compound lactic acid bacteria, Lactobacillus helveticus (commercially available) and Kluyveromyces marxe (commercially available), in which the amount of compound lactic acid bacteria added is 0.01 g / L, the amount of Lactobacillus helveticus added is 0.02 g / L, and the amount of Kluyveromyces marxis added is 0.01 g / L. The fermentation temperature was 32°C, and the fermentation time was 24 hours.

[0037] After ferm...

Embodiment 2

[0041] Take 12.50 kg of skimmed milk powder, add 30 kg of water, and dissolve at 40-50°C for about half an hour. Add 5kg of white sugar and fully dissolve it. 0.75kg of polydextrose was dissolved in 5kg of hot water, the temperature was controlled at 70-90°C, and sheared at 3000rpm for about half an hour. 0.20 kg of high acyl pectin was dissolved in 5 kg of hot water, the temperature was controlled at 70-90°C, and sheared at 3000 rpm for about half an hour. After mixing, make up to 50 L. Then kill at 90°C for 5 minutes. Cool quickly to room temperature. Inoculate compound lactic acid bacteria, Lactobacillus helveticus and Kluyveromyces marx, wherein the added amount of compound lactic acid bacteria is 0.01g / L, the added amount of Lactobacillus helveticus is 0.02g / L, and the added amount of Kluyveromyces marx is 0.01g / L. The fermentation temperature was 32°C, and the fermentation time was 24 hours.

[0042] After fermentation, stir to break the emulsion, and take 2L of fer...

Embodiment 3

[0046] Take 9.38kg of skimmed milk powder, add 25kg of water, and dissolve at 40-50°C for about half an hour. Add 5kg of white sugar and fully dissolve it. 0.50kg of polydextrose was dissolved in 8kg of hot water, the temperature was controlled at 70-90°C, and sheared at 3000rpm for about half an hour. 0.15 kg of high acyl pectin was dissolved in 8 kg of hot water, the temperature was controlled at 70-90°C, and sheared at 3000 rpm for about half an hour. After mixing, make up to 50 L. Then kill at 90°C for 5 minutes. Cool quickly to room temperature. Inoculate compound lactic acid bacteria, Lactobacillus helveticus and Kluyveromyces marx, wherein the added amount of compound lactic acid bacteria is 0.01g / L, the added amount of Lactobacillus helveticus is 0.02g / L, and the added amount of Kluyveromyces marx is 0.01g / L. The fermentation temperature was 32°C, and the fermentation time was 24 hours.

[0047] After fermentation, stir to break the emulsion, and take 2L of fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com