Trochoid oil pump

A kind of cycloid and trochoid technology, applied in the direction of pumps, pump components, rotary piston type/swing piston type pump components, etc., can solve the problem of difficult to prevent the pressure rise of the shrinking chamber, shrinking the gap to a small extent, and difficult to shrink the chamber. Connectivity and other issues to prevent erosion, reduce pulsation, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

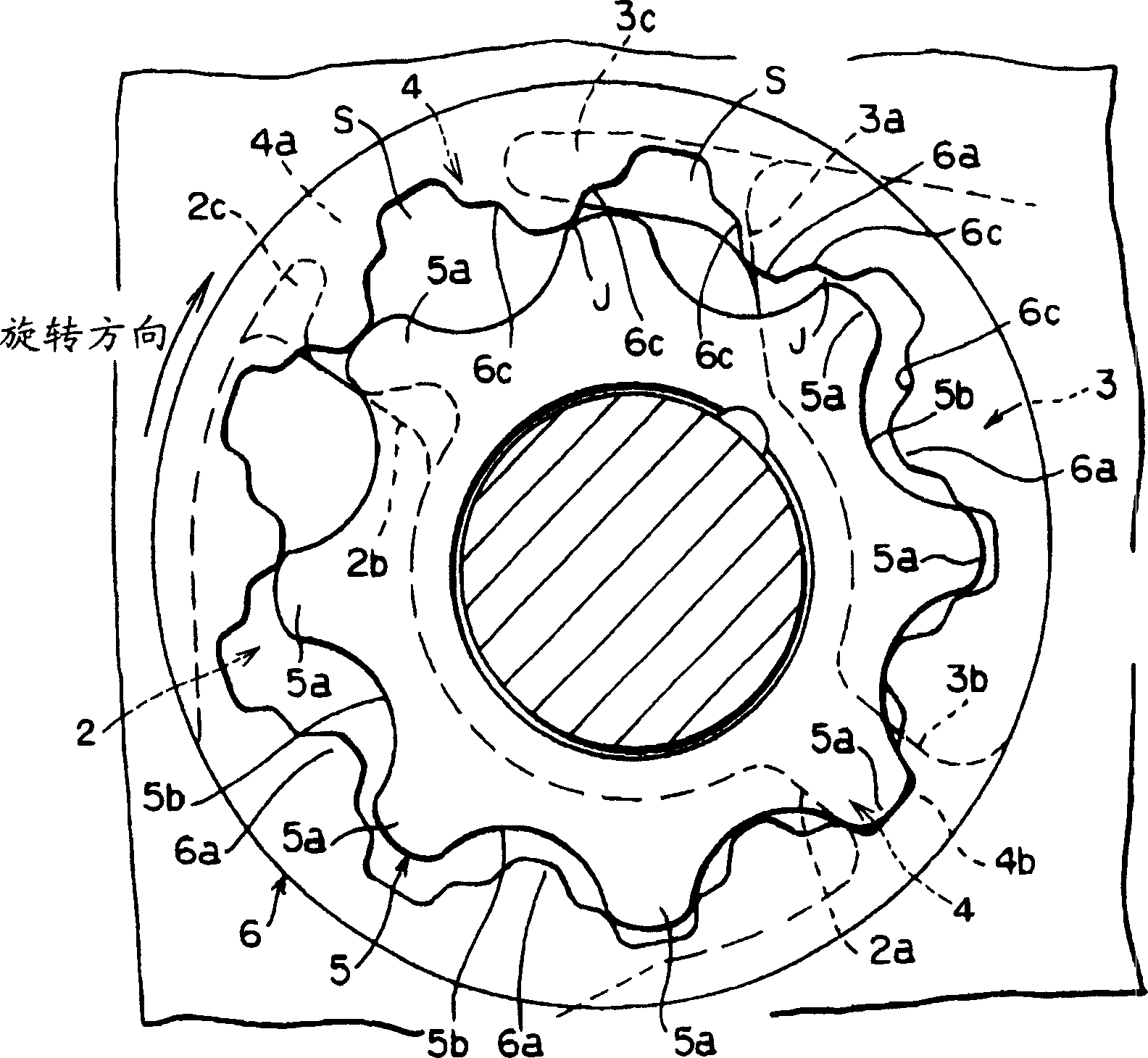

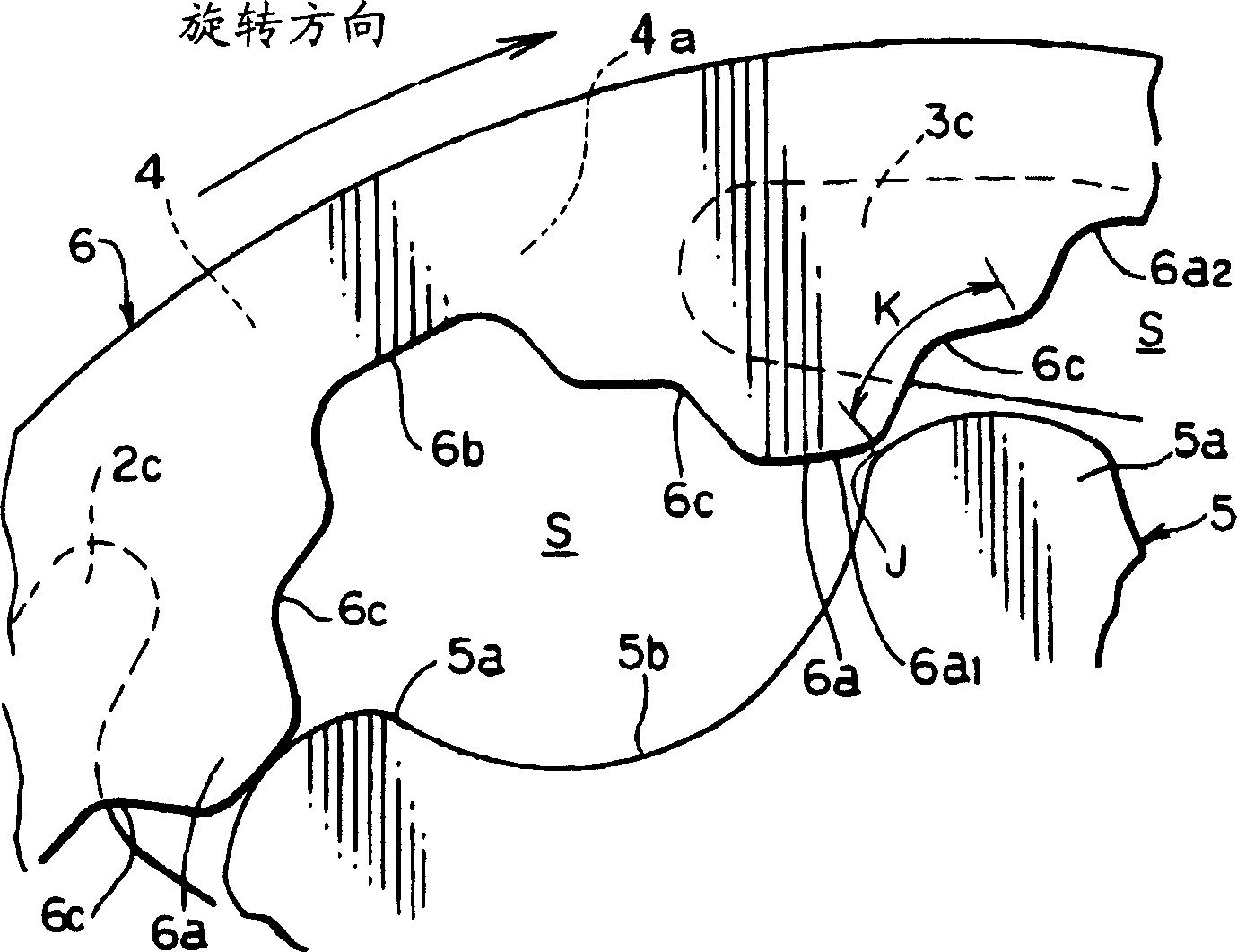

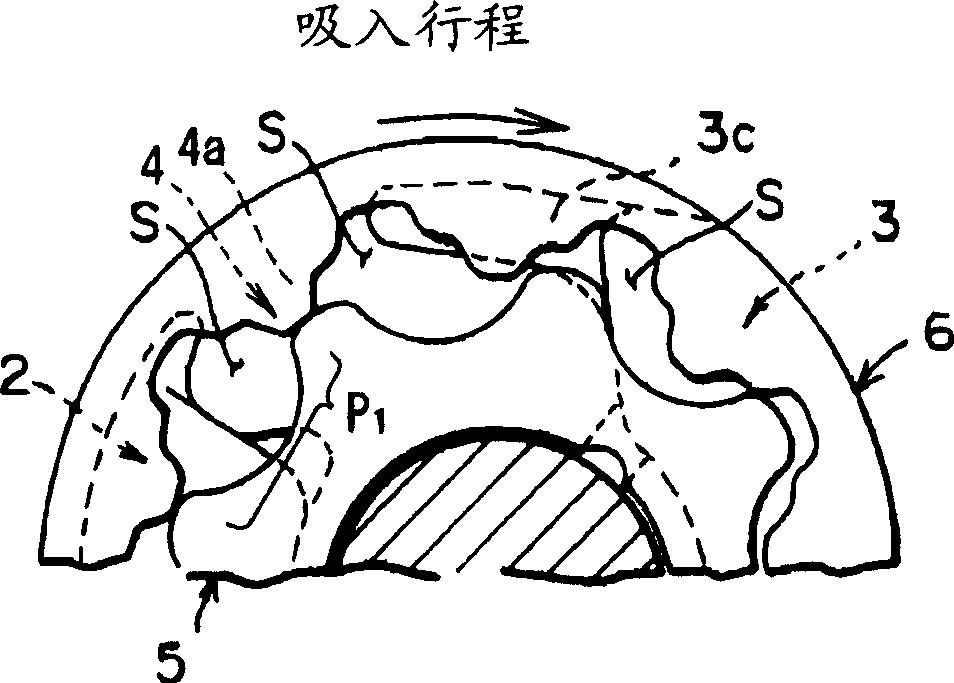

[0022] Hereinafter, the best mode for carrying out the present invention will be described based on the drawings. In the trochoid pump of the present invention, as shown in FIG. 1(A), a trochoid tooth-shaped inner rotor 5 and an outer rotor 6 are housed in a rotor chamber 1 formed in a pump casing. In the rotor chamber 1, as shown in FIG. 1(A), a suction port 2 and a discharge port 3 are formed substantially on the outer periphery along the circumferential direction thereof. Specifically, as shown in Figure 1(A), Figure 4 As shown in (A) etc., the suction port 2 and the discharge port 3 have left-right asymmetrical shapes, and the area area of the suction port 2 is formed larger than that of the discharge port 3 .

[0023] At the suction port 2, as shown in FIG. 1(A), the inter-tooth space S formed by the rotation of the inner rotor 5 and the outer rotor 6 moves, and the end portion of the area first reaching the above-mentioned suction port 2 becomes a suction port. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com