Liquid crystal display device and method for fabricating the same

A liquid crystal display and device technology, applied in the field of liquid crystal display devices, can solve the problems of reducing the light transmittance of the panel, increasing the cost, reducing the light transmittance of acrylic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

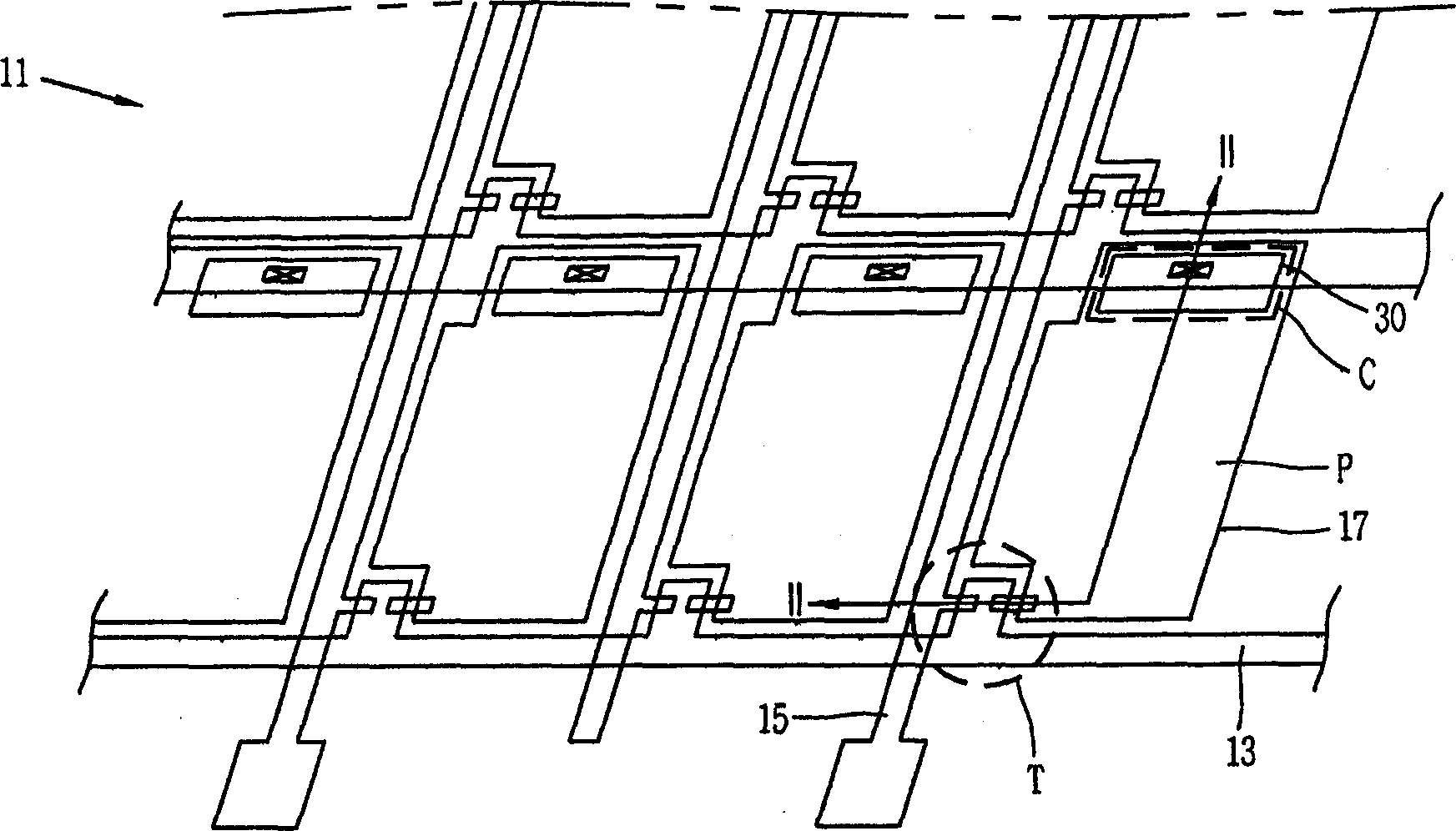

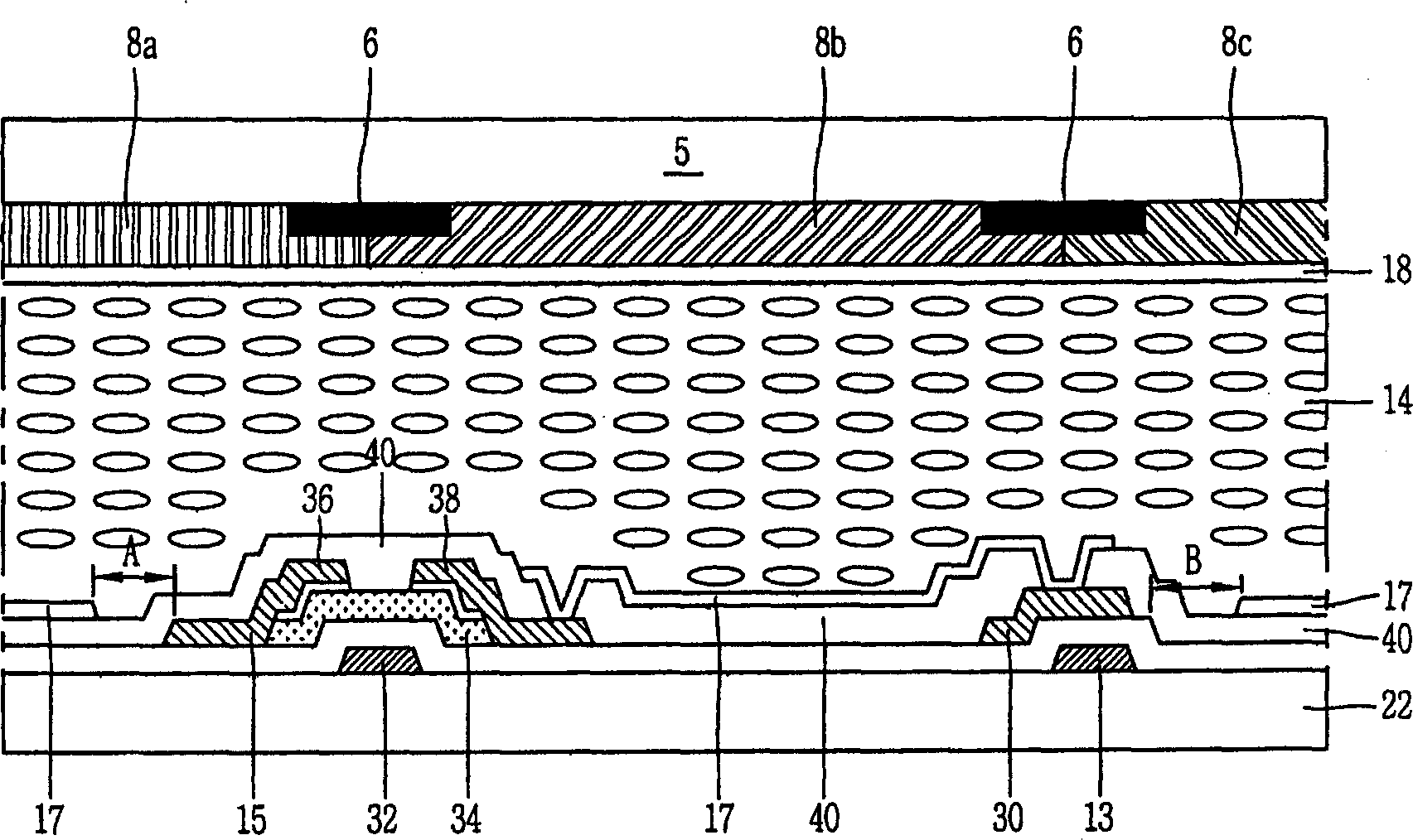

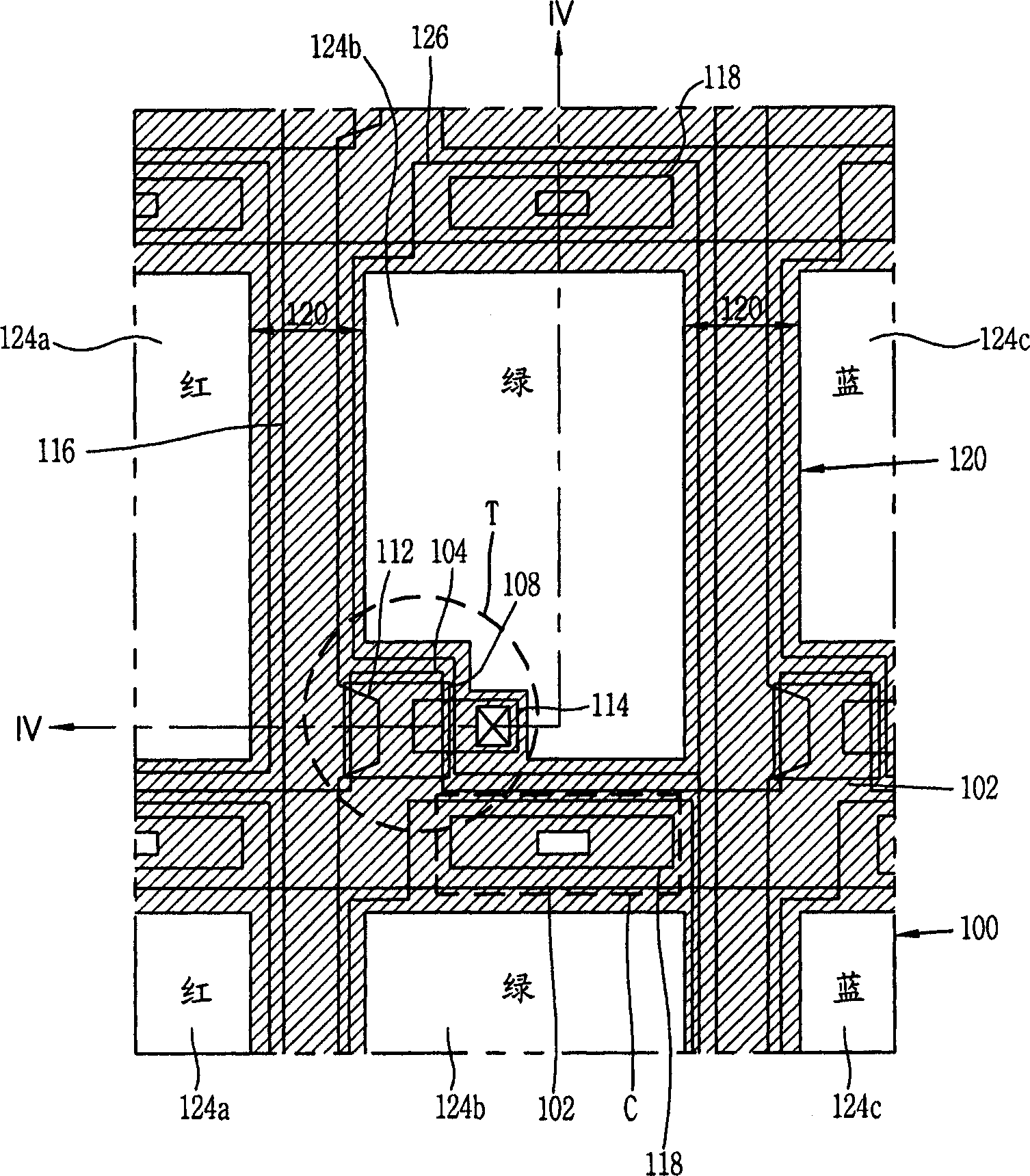

[0063] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

[0064] 5A to 5D are diagrams sequentially showing the layout of a liquid crystal display having a COT structure according to the present invention.

[0065] Referring to FIG. 5A , in the LCD device having a COT structure according to the present invention, gate lines 202 are horizontally arranged on the array substrate, and common electrode lines 206 are horizontally arranged at certain intervals from the gate lines 202 . Here, the common electrode line 206 includes a data line shielding common electrode 206a vertically arranged to minimize a crosstalk level and a storage capacitor portion 206b horizontally arranged to constitute a storage capacitor. Here, at least two data line shielding common electrodes 206a are arranged to face each other with a certain interval therebetween. Furthermore, in the gate patterning, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com