Thermoswitch

A thermal switch and moving contact technology, applied to thermal switch components, etc., can solve the problem of inability to obtain on-resistance, etc., and achieve the effect of small on-resistance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

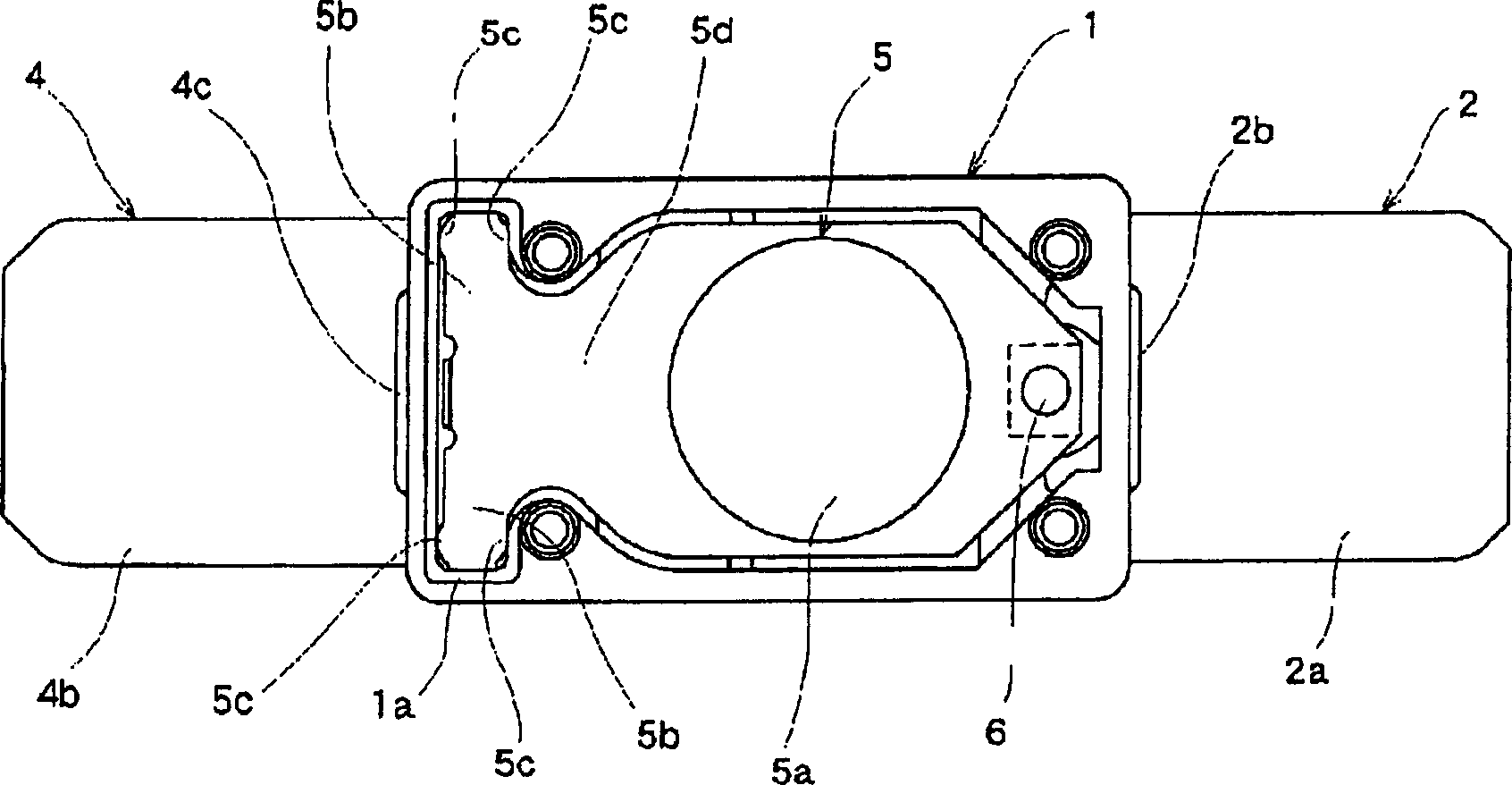

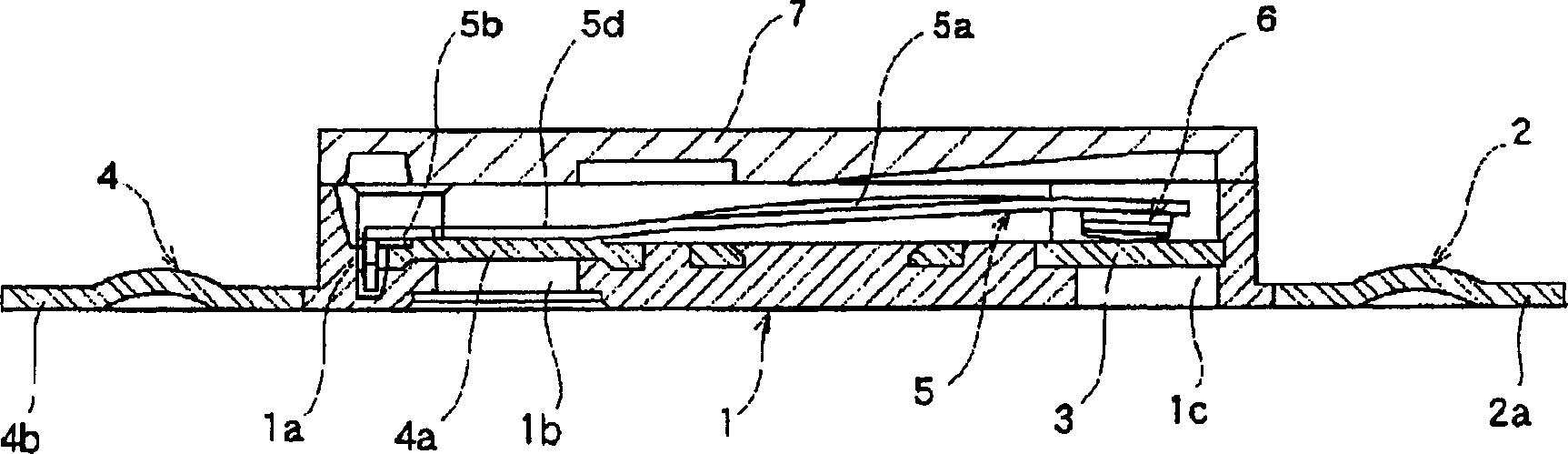

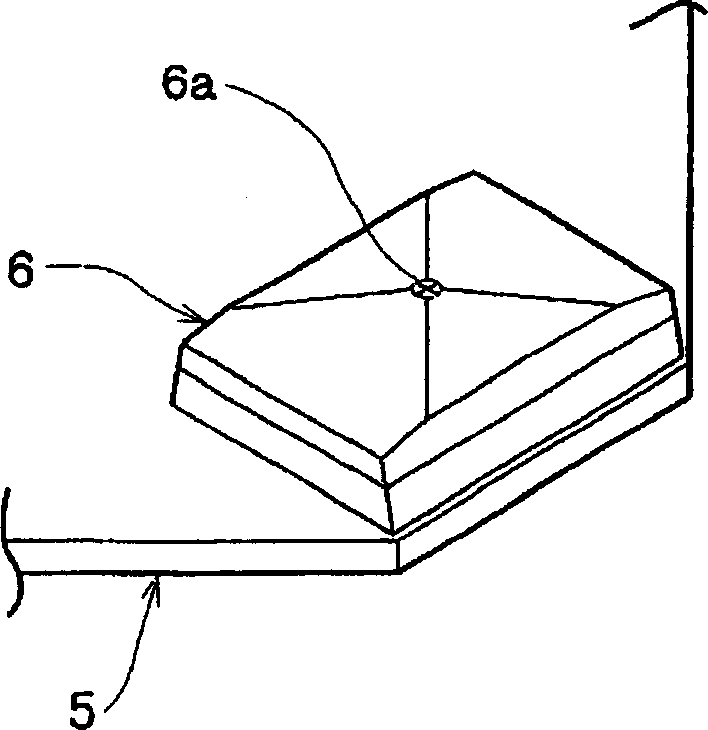

[0032] the following, Figure 1 to Figure 6 Examples of the present invention are shown. figure 1 It is a top view of the state of removing the cover of the thermal switch of the present invention; figure 2 is a sectional view of the thermal switch; image 3 is a perspective view showing the main part of the movable contact fixed to one end side of the bimetal; Figure 4 It is a perspective view of main parts showing a modified example of a movable contact fixed to one end side of a bimetal; Figure 5 is a cross-sectional view of the thermal switch showing the state before the bimetal is about to flip; Figure 6 It is an explanatory diagram showing the contact state of the movable contact and the fixed contact, (a) is a normal time, and (b) is an explanatory diagram immediately before turning over.

[0033] In the figure, the housing 1 is formed of an insulating material such as synthetic resin into a box shape with an open top. On the inner bottom of the housing 1 , te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com