Temperature controlled safety device in use for batteries, and method, and batteries with safety device being installed

A safety device and battery temperature technology, applied to battery components, electrical components, circuits, etc., can solve the problems that are difficult to control and ensure the stability and consistency of the battery pressure relief value, and the safety factor cannot be guaranteed, so as to achieve consistency , the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

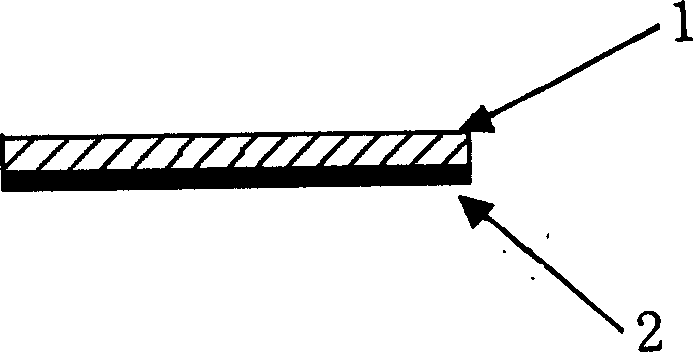

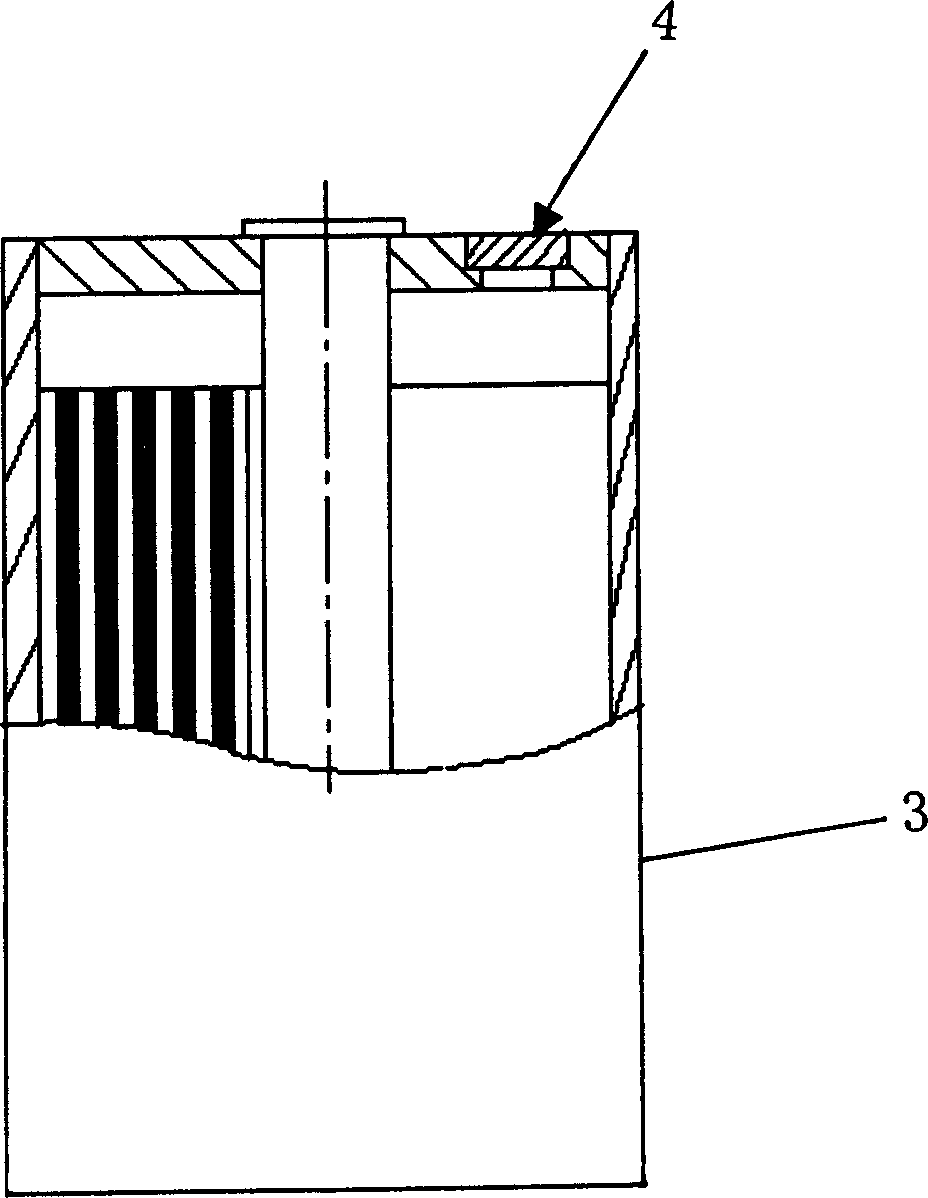

[0032] According to the law of battery temperature rise under battery abuse conditions, a safe temperature point can be selected to manufacture alloys with corresponding melting points.

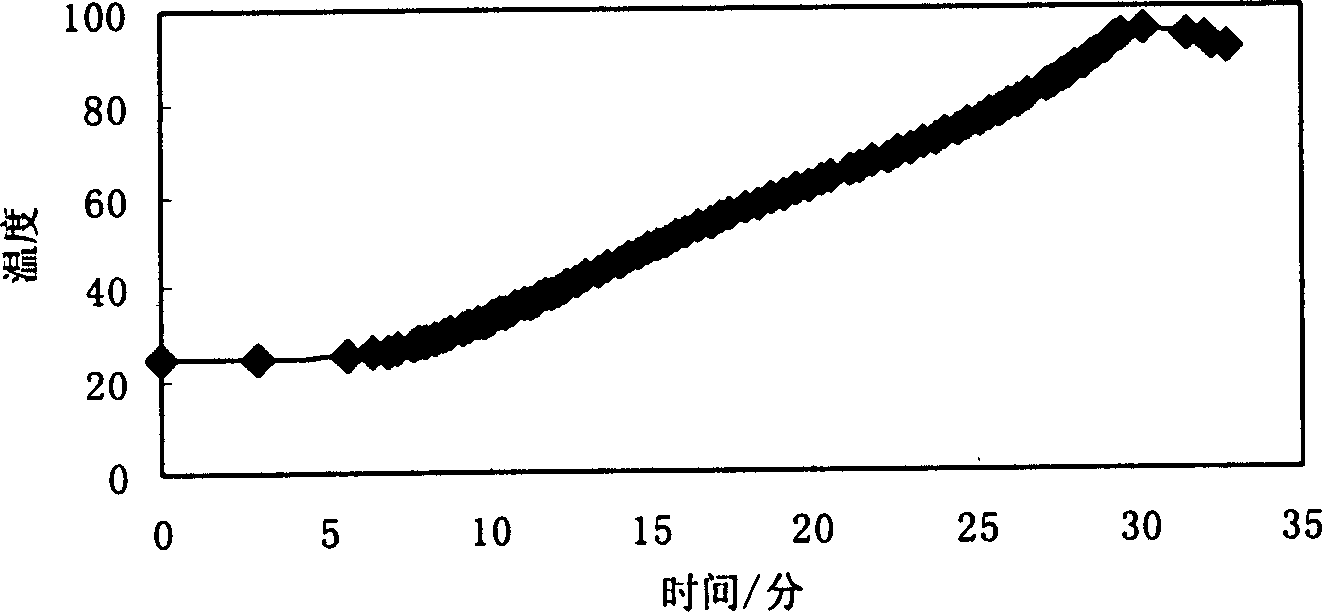

[0033] Using LiCoO 2 Make a lithium-ion battery as the positive electrode and carbon microspheres as the negative electrode. According to the structure of the battery, if the battery temperature rises under abuse conditions, when the battery temperature exceeds 58°C ± 2°C, the internal pressure of the battery will be too high to cause danger. According to this regularity, the temperature for controlling the cracking of the safety device is set to 58°C to manufacture a medium-low temperature fusible alloy with a corresponding melting point of 58°C, and the composition and weight percentage of the alloy are determined according to the melting point of the alloy to be made. Its composition and weight percentage are as follows: Bi 49%, In 21%, Pb 18%, Sn 12%.

[0034] Melt the above-mentioned a...

Embodiment 2

[0037] Example 2 is the same as Example 1 except that the alloy melting point, alloy composition and weight percentage are different from Example 1.

[0038] The melting point of the alloy is 108°C;

[0039] The composition and weight percentage of the alloy are as follows: In 52%, Sn 46%, Zn 2%.

[0040] In the destructive test, when the temperature of the battery rises to the melting temperature of the safety device (that is, the melting point of the alloy is 108°C), the safety device melts and releases the internal pressure of the battery, but the battery does not explode or catch fire.

Embodiment 3

[0042] Example 3 is the same as Example 1 except that the alloy melting point, alloy composition and weight percentage are different from Example 1.

[0043] The melting point of the alloy is 142°C;

[0044] The composition and weight percentage of the alloy are as follows: In 98%, Zn 2%.

[0045] In the destructive test, when the temperature of the battery rises to the melting temperature of the safety device (that is, the melting point of the alloy is 142°C), the safety device melts and releases the internal pressure of the battery, but the battery does not explode or catch fire.

[0046] In the present invention, the temperature range for controlling the cracking of safety devices is 50-200°C. Alloys at other temperatures other than those in Examples 1, 2, and 3 can be formulated according to the alloy components proposed in the present invention, and details will not be repeated here. Therefore, embodiments 1, 2, and 3 are just three examples, and do not limit the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com