High-density oxidized polyethylene wax preparation device and method

A technology for oxidizing polyethylene wax and a preparation device, applied in the field of polyethylene wax preparation, can solve the problems of difficult oxidation, low production efficiency, long oxidation time, etc., and achieve the effects of ensuring product quality, high production efficiency, and complete cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method comprises the following process steps:

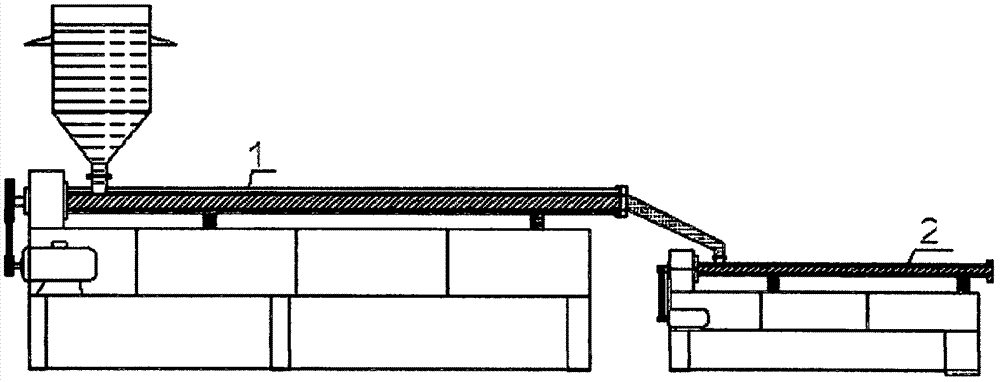

[0041] 1) Add polyethylene resin to the cracking device, that is, the screw cracking machine for cracking, set the cracking temperature of the main engine 1 to 200°C-490°C, and set the cracking temperature of the auxiliary machine 2 to 360°C-400°C. After cracking in the main machine 1 and auxiliary machine 2, the polyethylene resin can be cracked more thoroughly and fully to obtain polyethylene wax water; through the cracking of the main machine and auxiliary machine, high-density polyethylene wax water with relatively stable molecular weight and viscosity can be obtained.

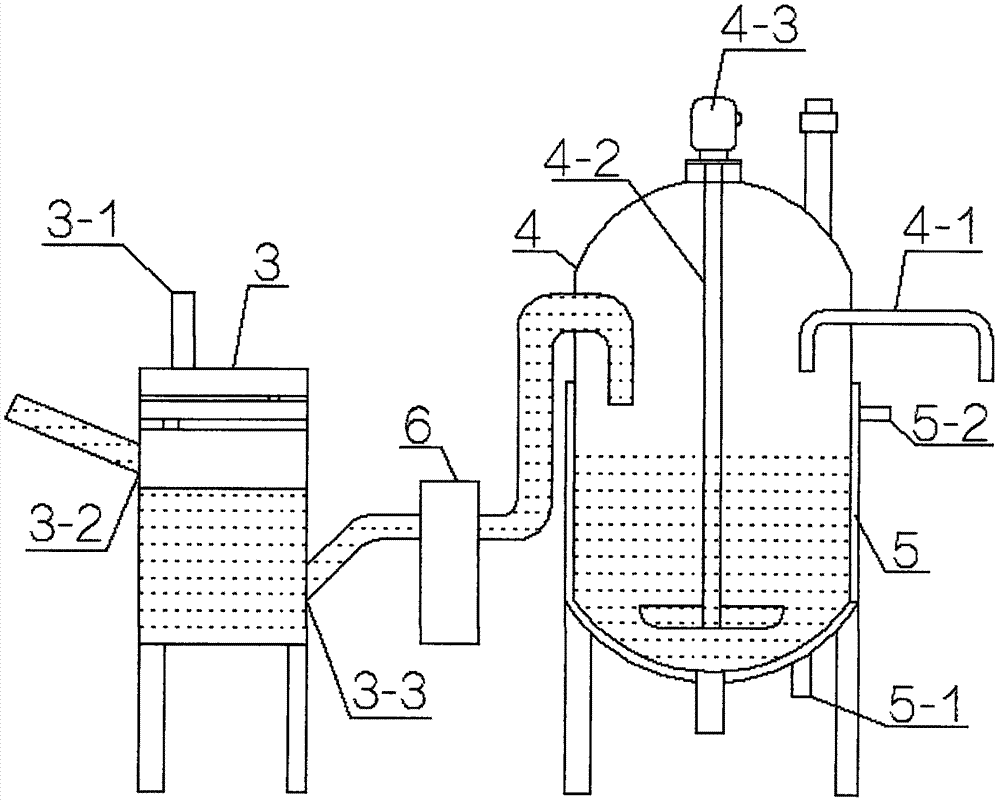

[0042] 2) The polyethylene wax wax water is injected into the collecting tank 3 through the pipeline to remove the oligomers and then cooled down to ensure that the material entering the oxidation reaction kettle has higher purity and better quality of the final product.

[0043]3), the polyethylene wax wax water after cooling is discha...

Embodiment 1

[0048] 500 kilograms of viscosity is that the polyethylene wax wax water of 7500mpa.s joins oxidation reactor, keeps temperature to

[0049] 145°C, add peracetic acid, the amount of peracetic acid added is 0.05% to 0.1%. Stir evenly and heat up to 150°C to 155°C to let air in, and the air flow rate is 3000L / H. Pressurize the oxidation reaction kettle to 1.5mpa, take a sample after timing the reaction for 3 hours to obtain oxidized polyethylene wax water with an acid value of 15mgKOH / G, and obtain oxidized wax water with an acid value of 30mgKOH / G after 5 hours of reaction.

Embodiment 2

[0051] Add 500 kg of polyethylene wax water with a viscosity of 2500mpa.s into the oxidation reactor, keep the temperature at 145° C., and add peracetic acid in an amount of 0.05% to 0.1%. Stir evenly and raise the temperature to 150°C to 155°C to let air in, the air flow rate is 3000L / H, that is, the air flow rate per hour is 3000L. Pressurize the oxidation reaction kettle to 1.5mpa, take a sample after timing the reaction for 2 hours to obtain oxidized polyethylene wax water with an acid value of 15mgKOH / G, and obtain oxidized wax water with an acid value of 30mgKOH / G after 4 hours of reaction.

[0052] The method of the present invention sets different reaction times according to different performance requirements of desired products.

[0053] The invention adopts a screw-type cracking machine including a main engine and an auxiliary machine to crack the high-density polyethylene resin, and can well control the cracking temperature, molecular weight and viscosity.

[0054]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com