Two-segment differential type planetary gear train driver

A technology of planetary gear system and planetary gear set, which is applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems of poor motor transmission efficiency, large backlash wear, low efficiency, etc., and achieve deceleration transmission efficiency High, high torsional energy loss, ultra-high transmission efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: The reduction ratio of the planetary gear set is low to be suitable for multi-rotation valve drivers (in this embodiment, a power is input through the hand wheel)

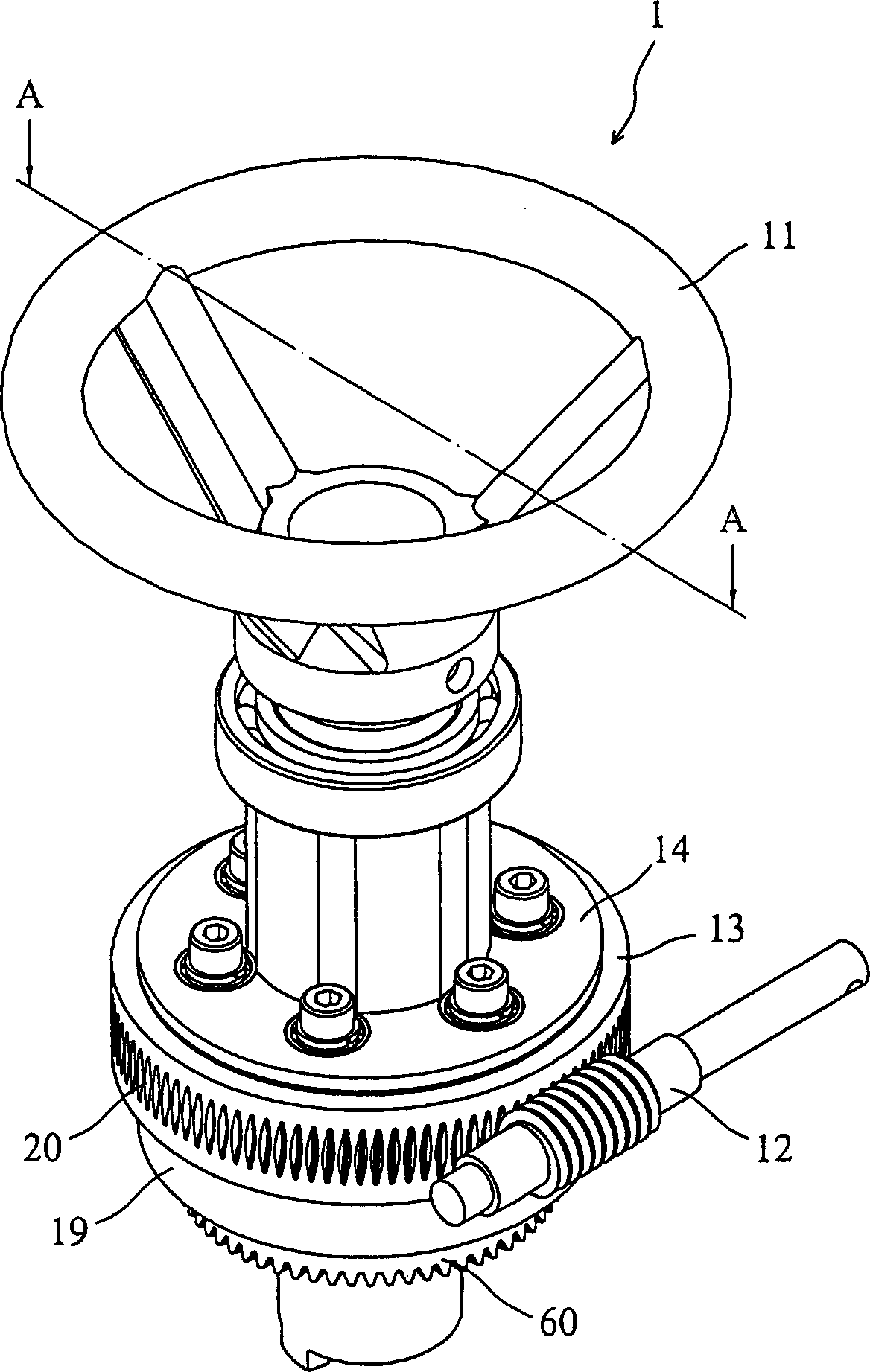

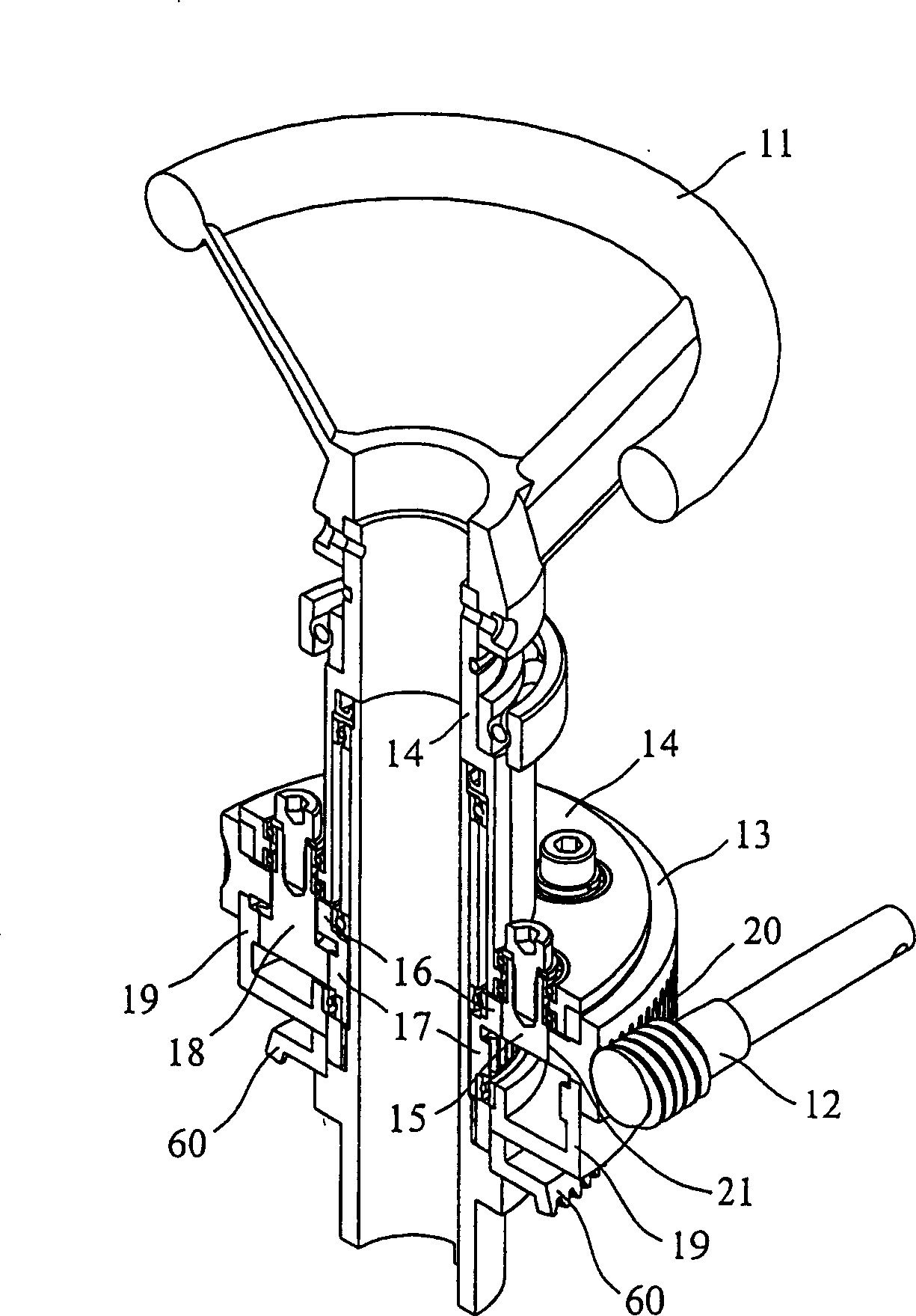

[0053] see figure 1 , showing a perspective view of a two-stage differential planetary gear train driver in Embodiment 1 of the present invention, figure 2 for figure 1 Sectional view of midline A-A. The two-stage differential planetary gear train driver 1 of this embodiment includes: a hand wheel 11, a first stage planetary gear set, a second stage planetary gear set and a worm 12, and the hand wheel 11 is locked and connected to the first stage The swing arm drive element 14 of the planetary gear set, the first stage planetary gear set includes a fixed ring element 13, a swing arm drive element 14, the upper planetary gear set passive element 15 and the upper sun gear passive element 16, the second stage The planetary gear set includes a lower sun gear drive element 17 , a lower planeta...

Embodiment 2

[0056] Embodiment 2: The reduction ratio of the planetary gear set is low to be suitable for multi-rotation valve drivers (in this embodiment, a power is input via a motor)

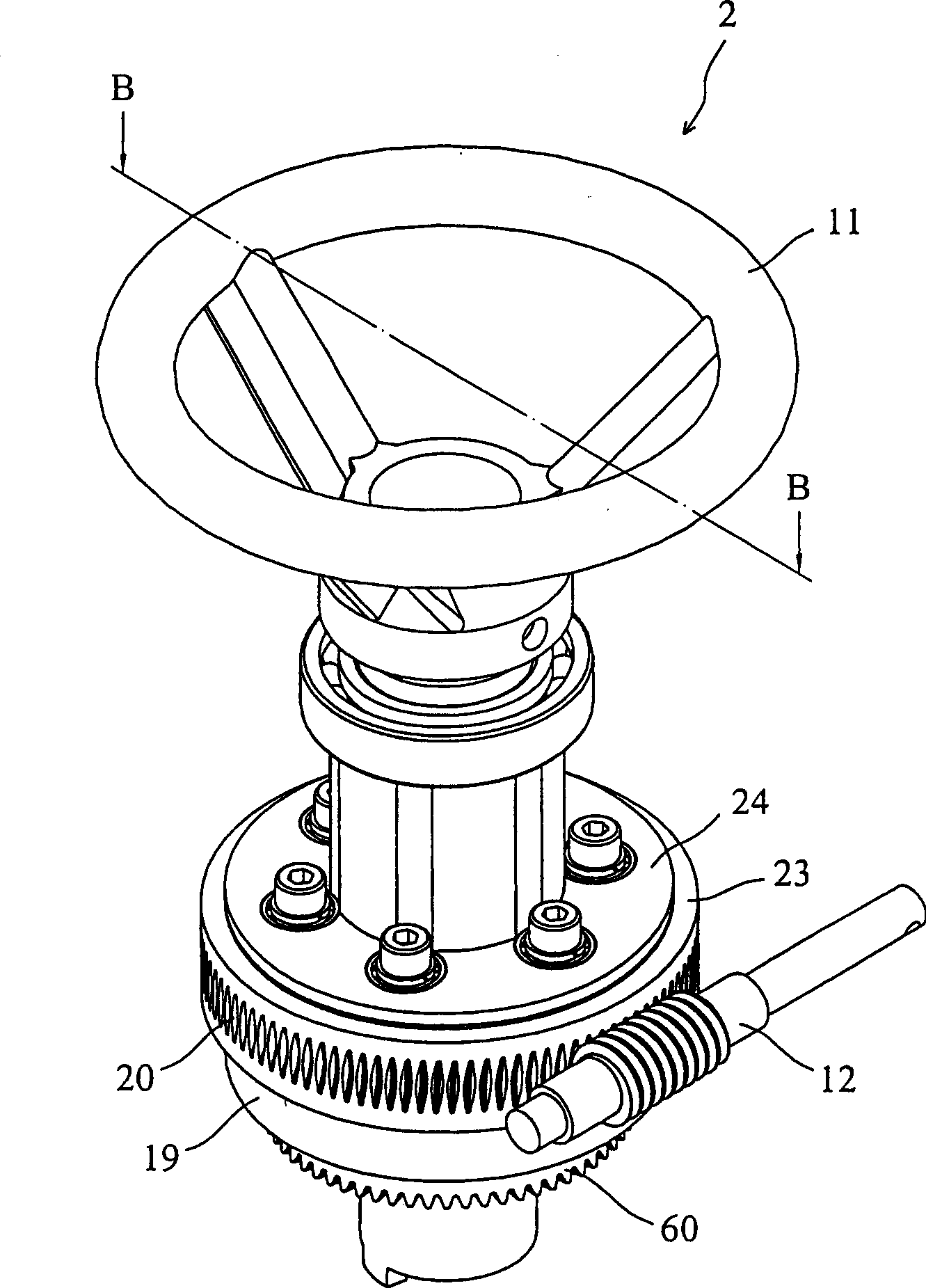

[0057] see image 3 , showing a perspective view of the two-stage differential planetary gear train driver in Embodiment 2 of the present invention, Figure 4 for along image 3 Sectional view of line B-B in. The two-stage differential planetary gear train driver 2 of this embodiment includes: a hand wheel 11, a first stage planetary gear set, a second stage planetary gear set and a worm 12, and the hand wheel 11 is locked and connected to the first stage The swing arm fixed element 24 of the planetary gear set, the first stage of the planetary gear set includes a swing arm fixed element 24, a driving ring element 23, the upper planetary gear set passive element 15 and the upper sun gear passive element 16, the second stage The planetary gear set includes a lower sun gear drive element 17 , a lower pla...

Embodiment 3

[0061] Embodiment 3: The reduction ratio of the planetary gear set is high to be suitable for the 1 / 4 turn type valve driver (in this embodiment, a power is input through the hand wheel)

[0062] see Figure 5 , showing a perspective view of the two-stage differential planetary gear train driver in Embodiment 3 of the present invention, Figure 6 for along Figure 5 The sectional view of the line C-C (omit the spur gear 53, the worm 54 and the hand wheel 55). The two-stage differential planetary gear train driver 3 of this embodiment includes: a spur gear 53, a first stage planetary gear set, a second stage planetary gear set and a hand wheel 55, and the first stage planetary gear set includes a spiral arm Fixed element 34, a driving ring element 33, an upper planetary gear set passive element 35 and an upper sun gear passive element 36, and the second stage planetary gear set includes a lower sun gear driving element 37, a lower planetary gear set driving element 38 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com