Electrical threader for building construction

A technology of building construction and lead wire device, applied in cable laying equipment and other directions, can solve the problems of time-consuming, stuck, affecting the quality of infrastructure construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

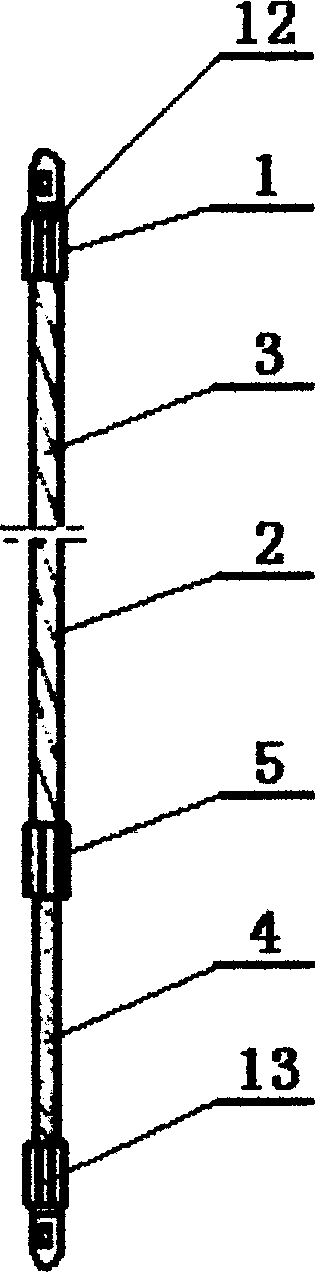

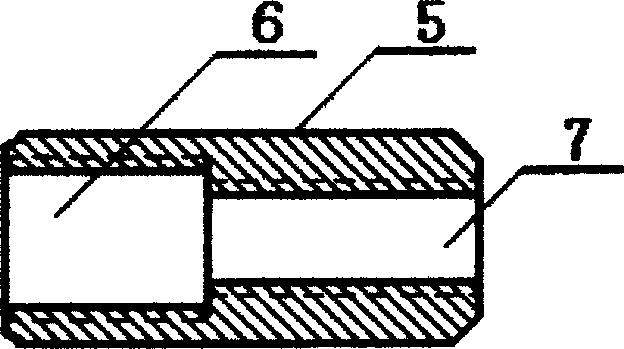

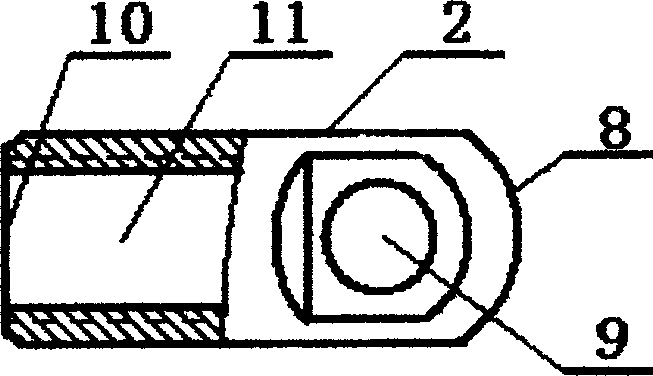

[0016] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

[0017] exist figure 1 , figure 2 and image 3 Among them, the electrical threader for building construction of the present invention is mainly composed of a guide wire 1 and a guide head 2 . The guide wire 1 is formed by connecting a thicker and harder main lead wire 3 and a thinner and softer front lead wire 4 through an intermediate transition joint 5 . Among them: the thicker and harder main lead wire 3 is a plastic wire rope twisted by three PET plastic wires mixed with 10%-30% glass fiber inside, and the unit breaking rate of the single-strand PET plastic wire is not Less than 200Kg, when the natural bending degree is equal to 90°, the resilience is 100%. After heat treatment, it is tightly integrated and does not loosen. The tensile force of the plastic cord after plying is greater than 600Kg; the thinner and softer front lead Series ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pull | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com