Air cleaner, functional filter and method of manufacturing the filter, air cleaning filter, and air cleaner device

An air cleaning and filter technology, applied in filtration separation, separation methods, dispersed particle filtration, etc., can solve problems such as raw material restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

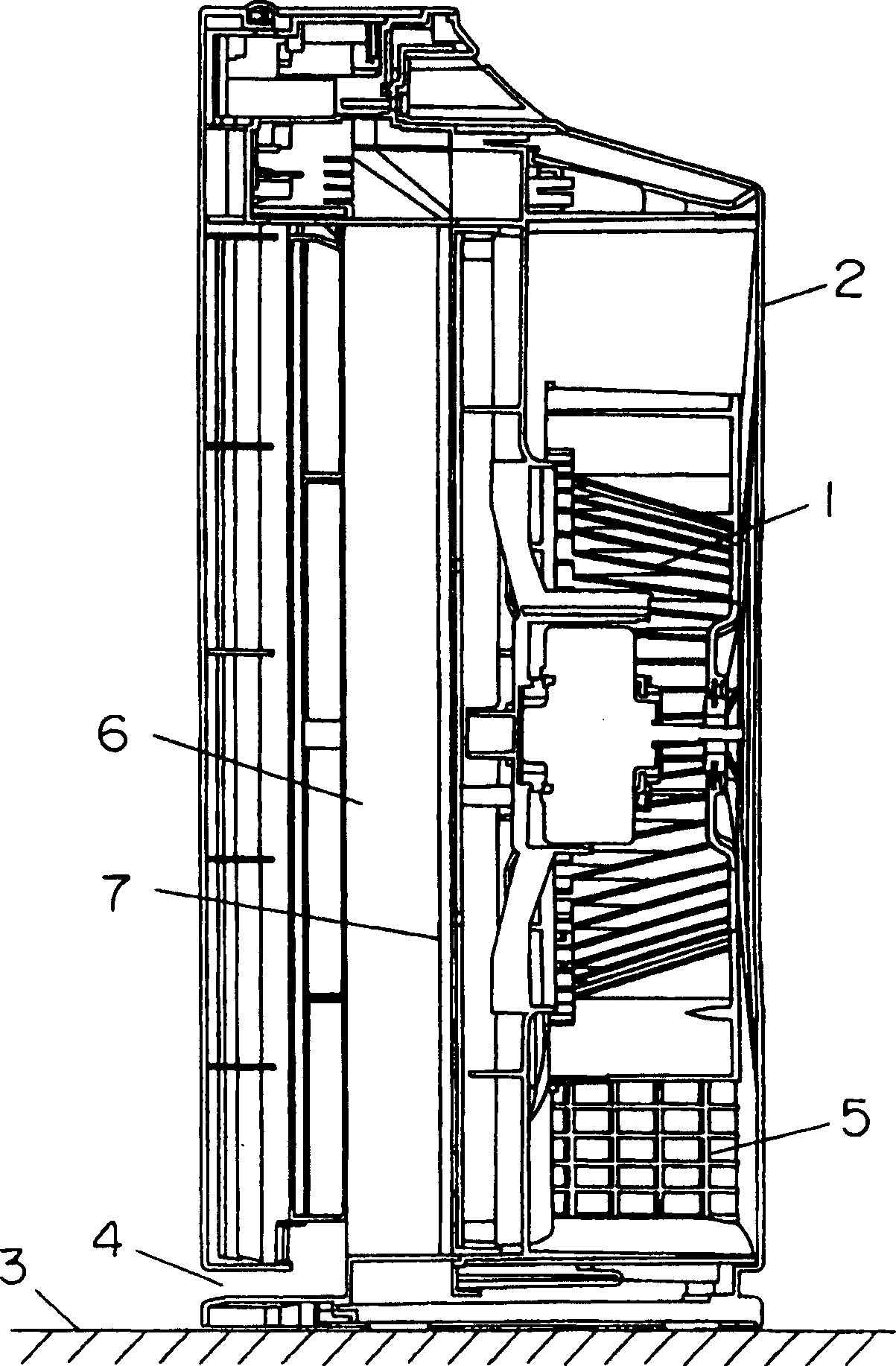

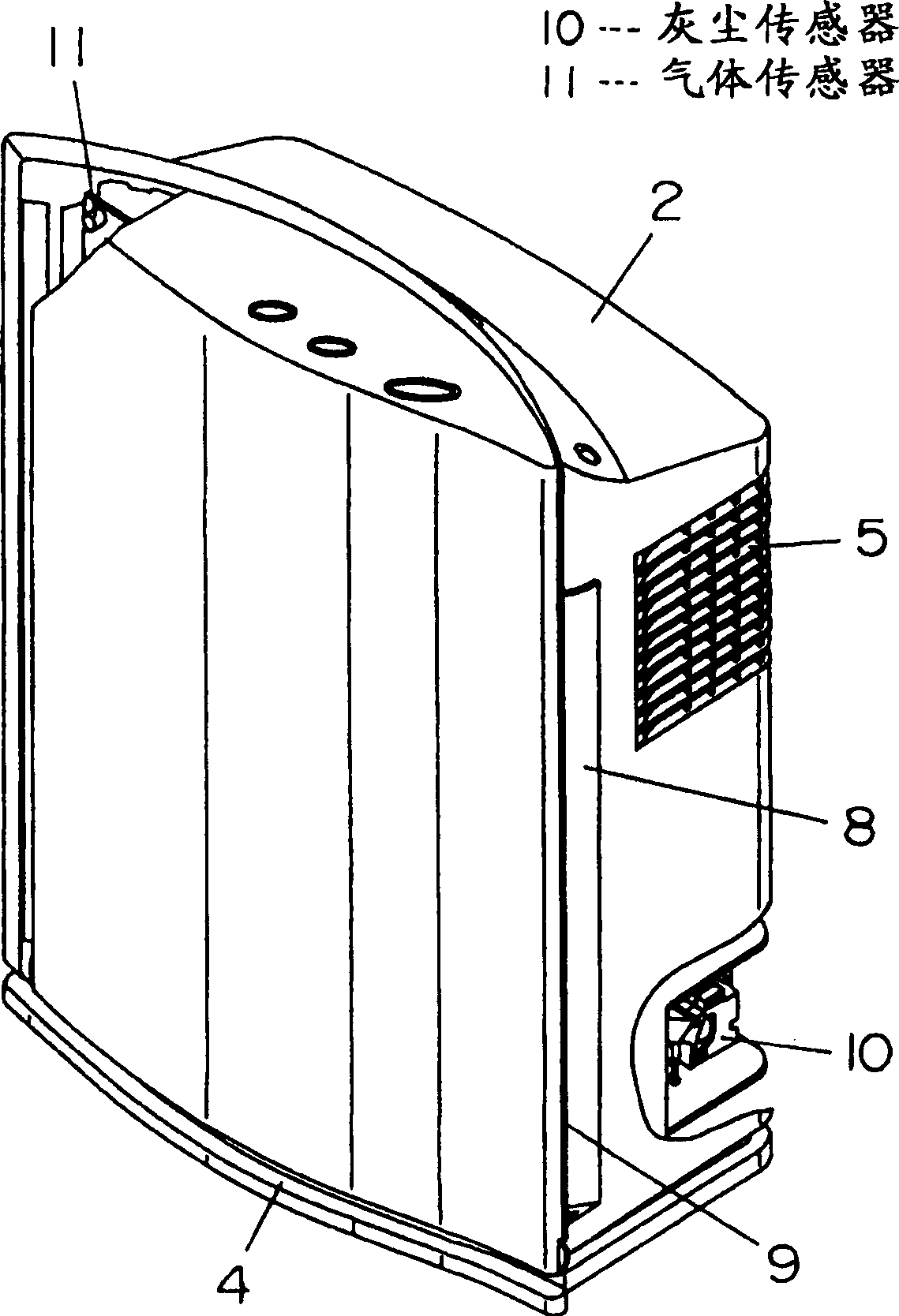

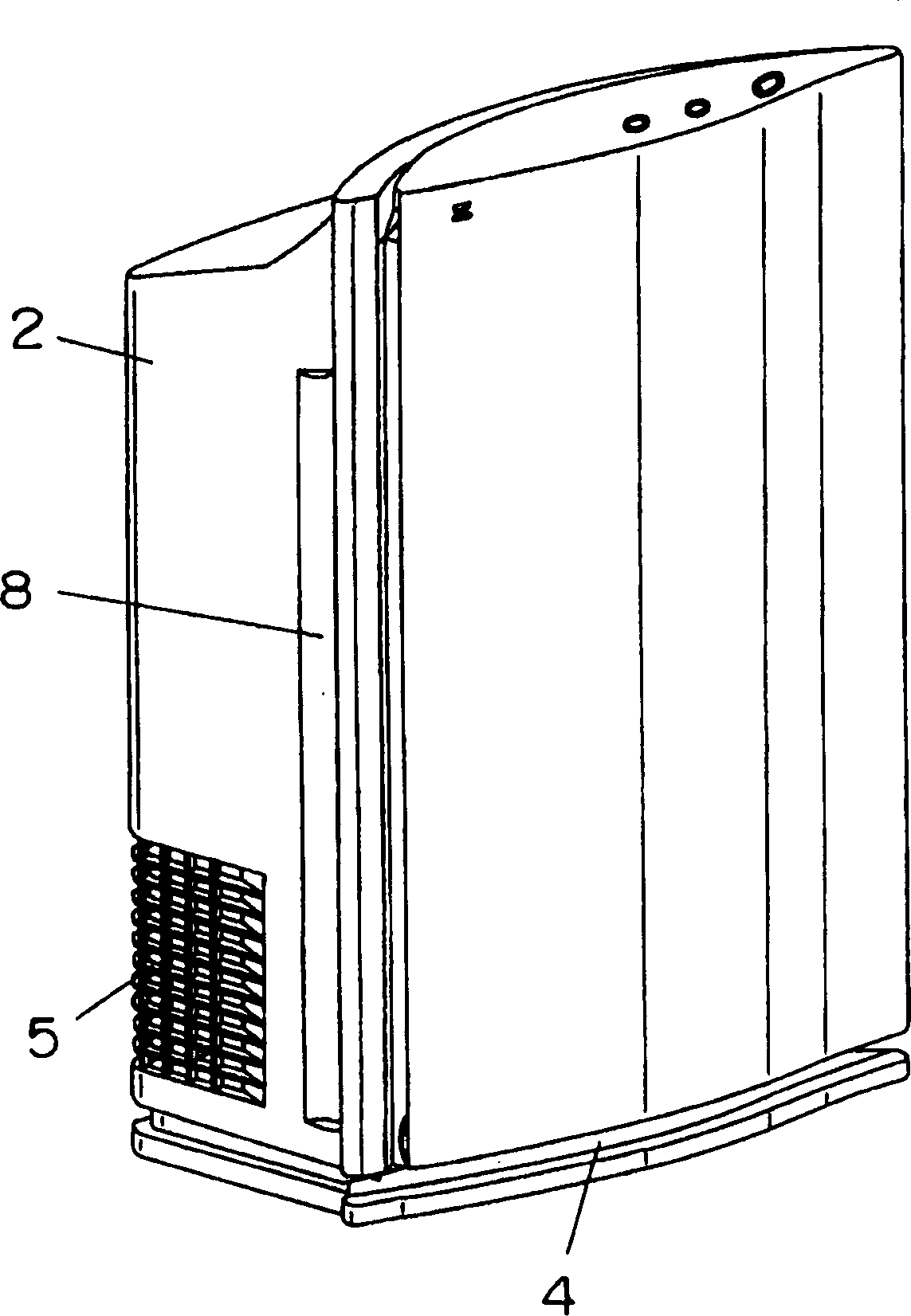

[0113] Figure 1~ Figure 5 As shown, the front lower part of the main body 2 provided with the blower mechanism 1 is provided with a suction port 4 which forms a suction air flow along the ground 3 provided by the main body 2 and an air outlet 5 is provided on both sides of the main body 2 .

[0114] An anti-allergen filter sheet 6 and a deodorizing filter sheet 7 are arranged on the air channel of the blower mechanism 1 . Although the anti-allergen filter sheet 6 is to coat the aromatic hydroxyl compound made of polyvinylphenol on the high-performance filter sheet made of glass fiber, the filter sheet can be used for non-woven fabrics, electret filter sheets, honeycomb Filters, ヘバフイルタ, etc. can be appropriately selected according to needs.

[0115] In addition, an auxiliary suction port 8 is provided on the side of the main body 2, and in front of the auxiliary suction port 8, a shielding portion 9 protruding from the side of the main body 2 is provided so that the auxiliary...

Embodiment 2

[0134] Mixture of water-soluble and water-insoluble materials

[0135] As shown in Table 1, water-soluble materials and water-insoluble materials were mixed. After the components were mixed at a ratio (volume ratio) of 15% to the solvent, the mixture was stirred with a stirrer for one minute, and the state of the solution after stirring was visually observed.

[0136] In a single-component solvent, if a water-soluble material and a water-insoluble material are mixed, precipitation, two-phase separation, and a state where only a small amount of dissolution is observed. In the mixed liquid in which precipitation occurs and the two phases are separated, it is not suitable for practical use because it cannot be applied uniformly when applied to a filter. In addition, when only a small amount can be dissolved, only a small amount of components can be coated on the filter in one process, so the loss in production is large.

[0137] When the ratio of butyl celusoff and water in the...

Embodiment 3

[0142] Apply treatment liquid to the filter and dry

[0143] Prepare a treatment solution by dissolving catechin and polyvinylphenol in a mixed solvent of water / cellusophane at a concentration (volume ratio) of 15%, and immerse a polyester non-woven fabric filter in the treatment solution . The filter was lifted from the treatment liquid, and dried at room temperature, 100°C, 150°C, and 200°C, respectively. When drying at room temperature, it takes about 4 hours for the filter surface to feel that there is no liquid attached to it by hand. When drying at 100°C, it takes 15 minutes to reach the same degree of dry state. When dried at 150°C, the same degree of dry state was achieved in 10 minutes, but the color changed locally. Discoloration and shrinkage of the filter can be seen in 10 minutes at 200°C. The same result was obtained even when a polypropylene honeycomb filter was used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com