Controllable cooling method for thick steel plate, thick steel plate manufactured by the controllable cooling method, and cooling device for the thick steel plate

A technology for controlling cooling and steel plates, applied in metal processing equipment, temperature control, heat treatment equipment, etc., can solve problems such as overcooling and increasing water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

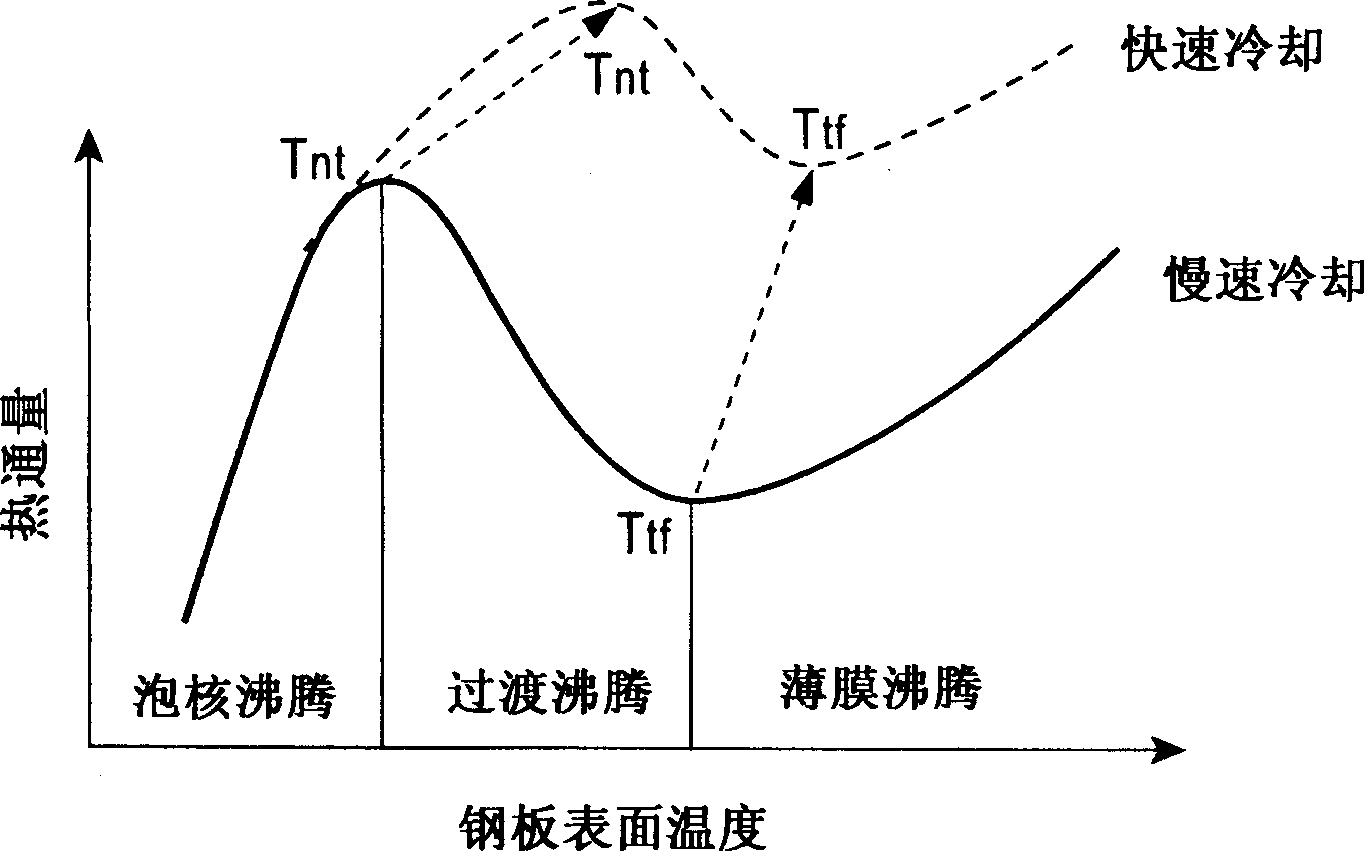

Problems solved by technology

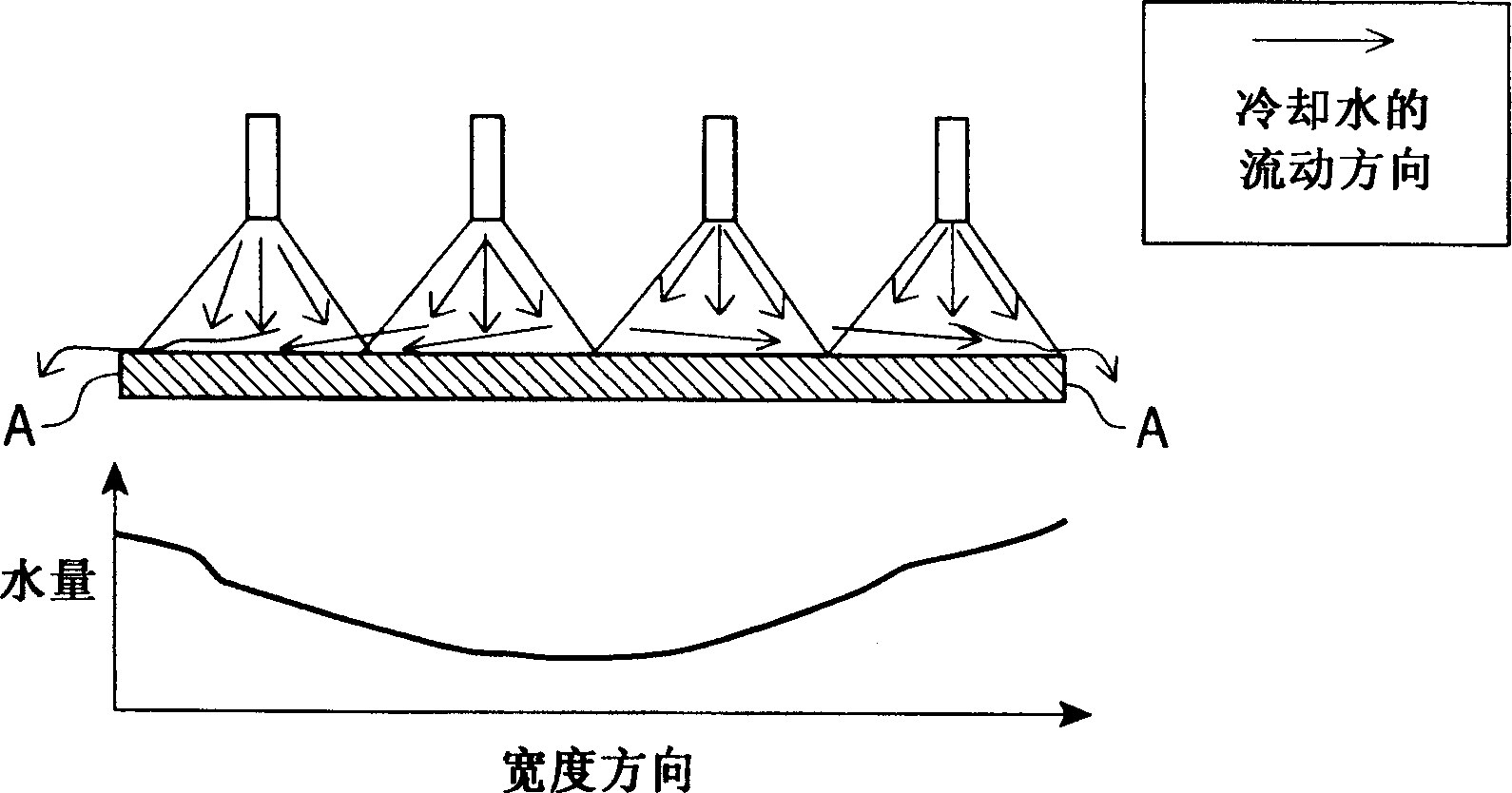

Method used

Image

Examples

example

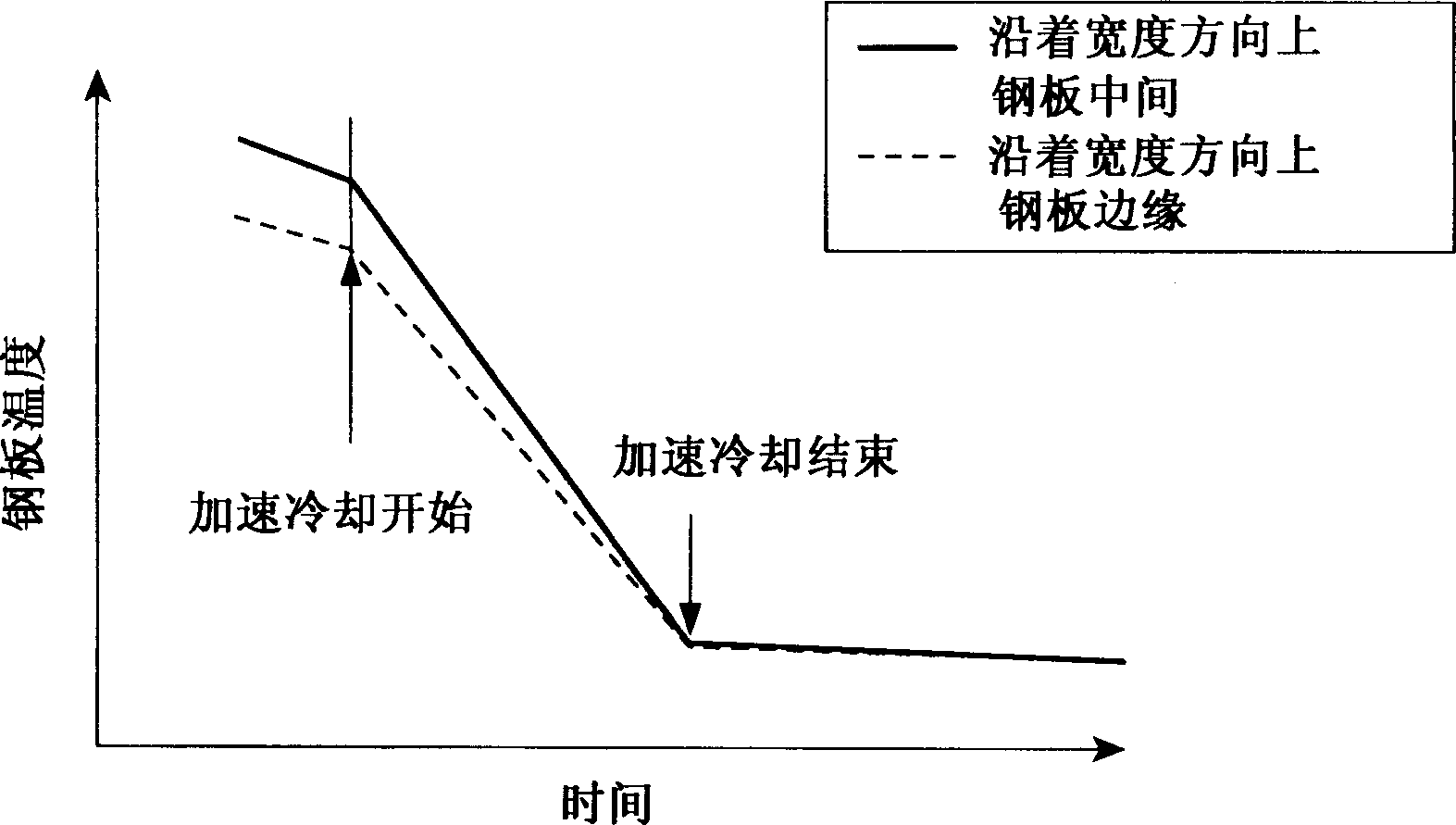

[0163] Table 1 shows the working conditions of the controlled cooling according to the present invention and the controlled cooling according to the existing method (comparative example). Table 2 shows the comparison between the effects of the above two methods. The condition of the processed steel plate is described as follows: the thickness of the steel plate is 25 mm, the width is 3,800 mm, and the length used is 25 m. Controlled cooling started from a temperature of 750°C at the middle of the steel sheet along the width direction and ended at 550°C. The strength of the steel plate is 490MPa level. Its allowable range is 490-610MPa. before cooling, in Figure 9 Among them, the temperature drop at each edge of the steel plate along the width direction is 30°C, and the temperature drop distance at each edge of the steel plate along the width direction is 200mm. exist Figure 14 , the temperature drop at each of the top and tail ends of the steel plate along the longitudi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com