Supercritical pressure regulation of economized refrigeration system.

一种制冷系统、制冷剂的技术,应用在制冷机、制冷组件、制冷和液化等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

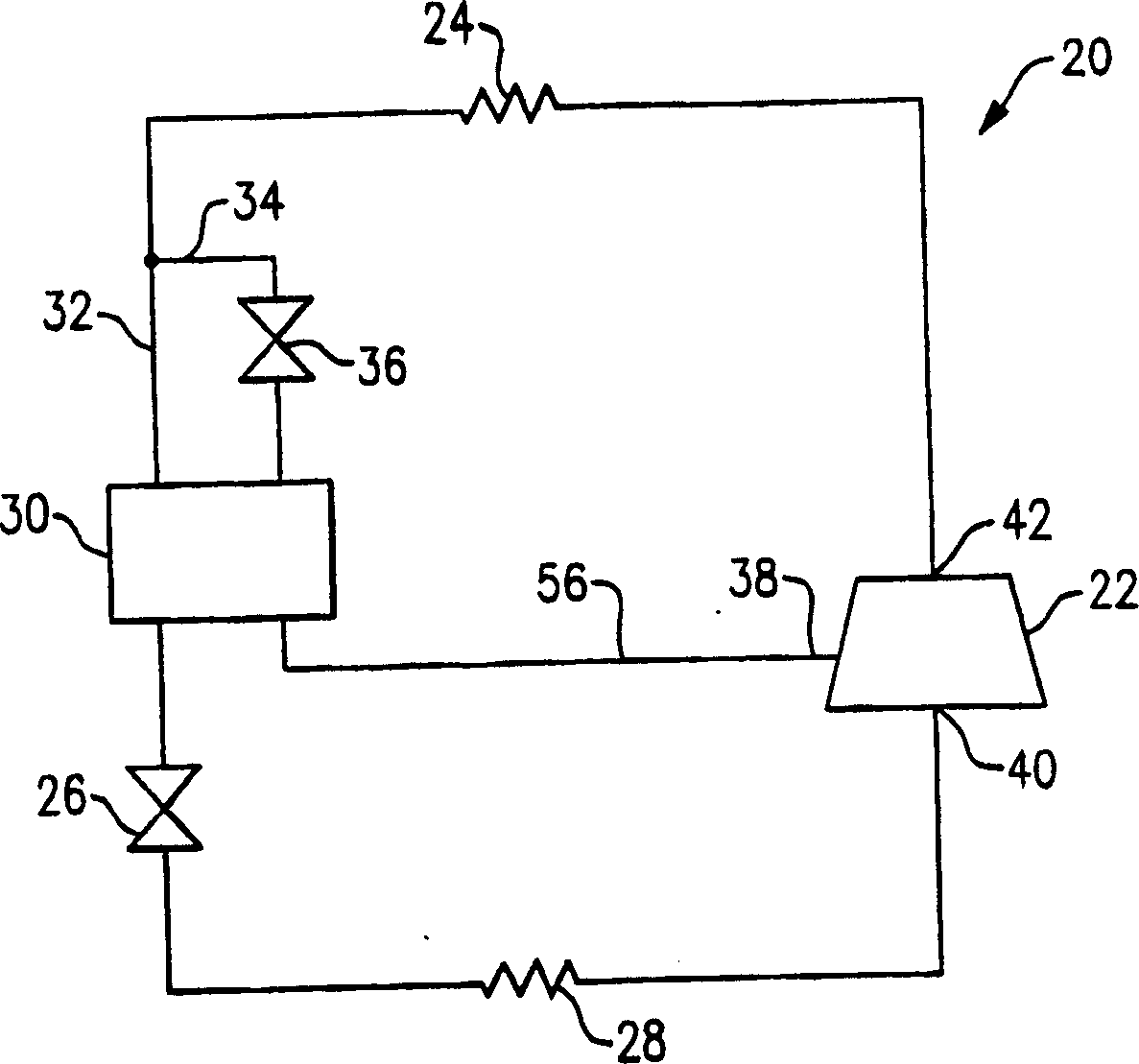

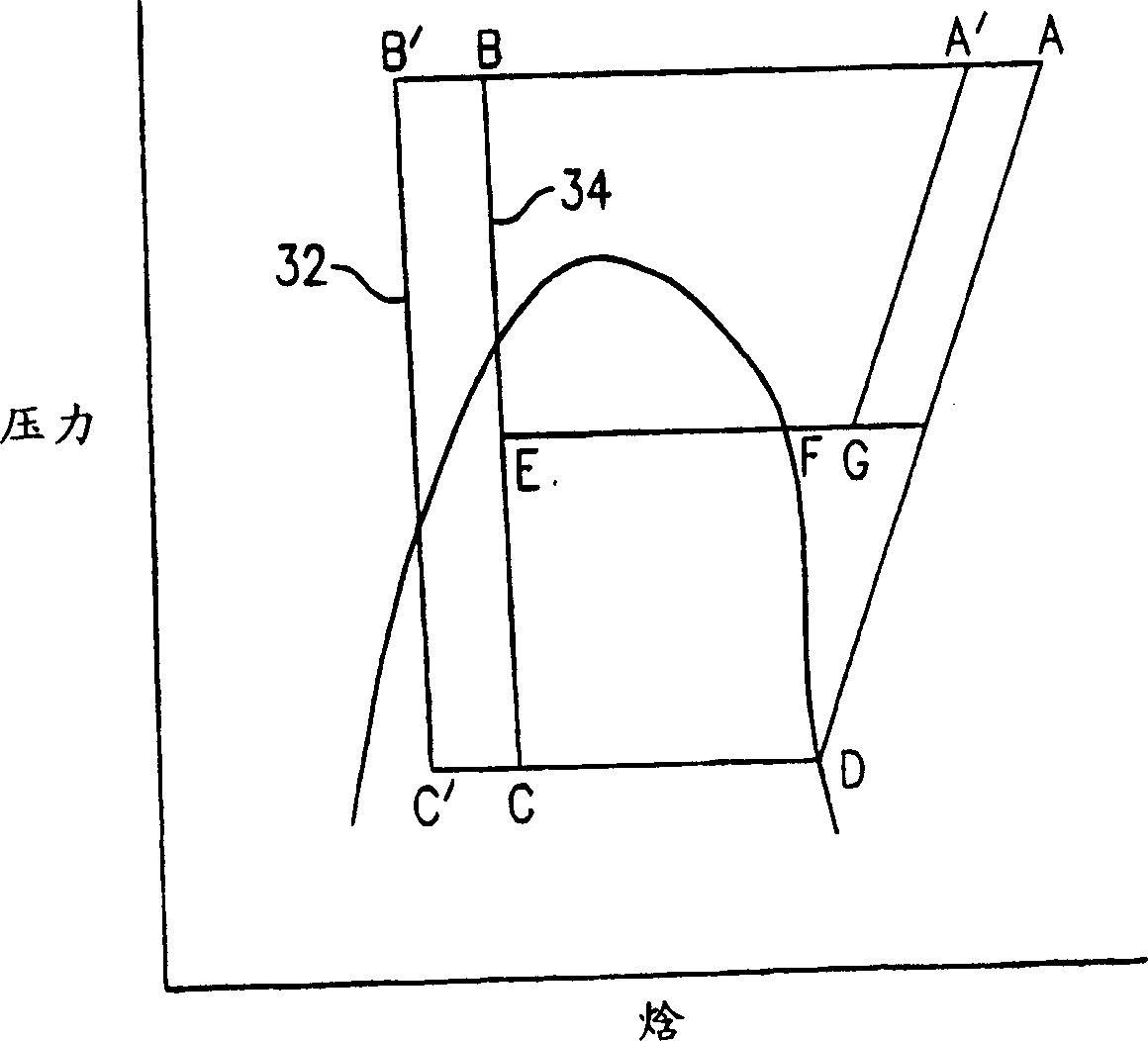

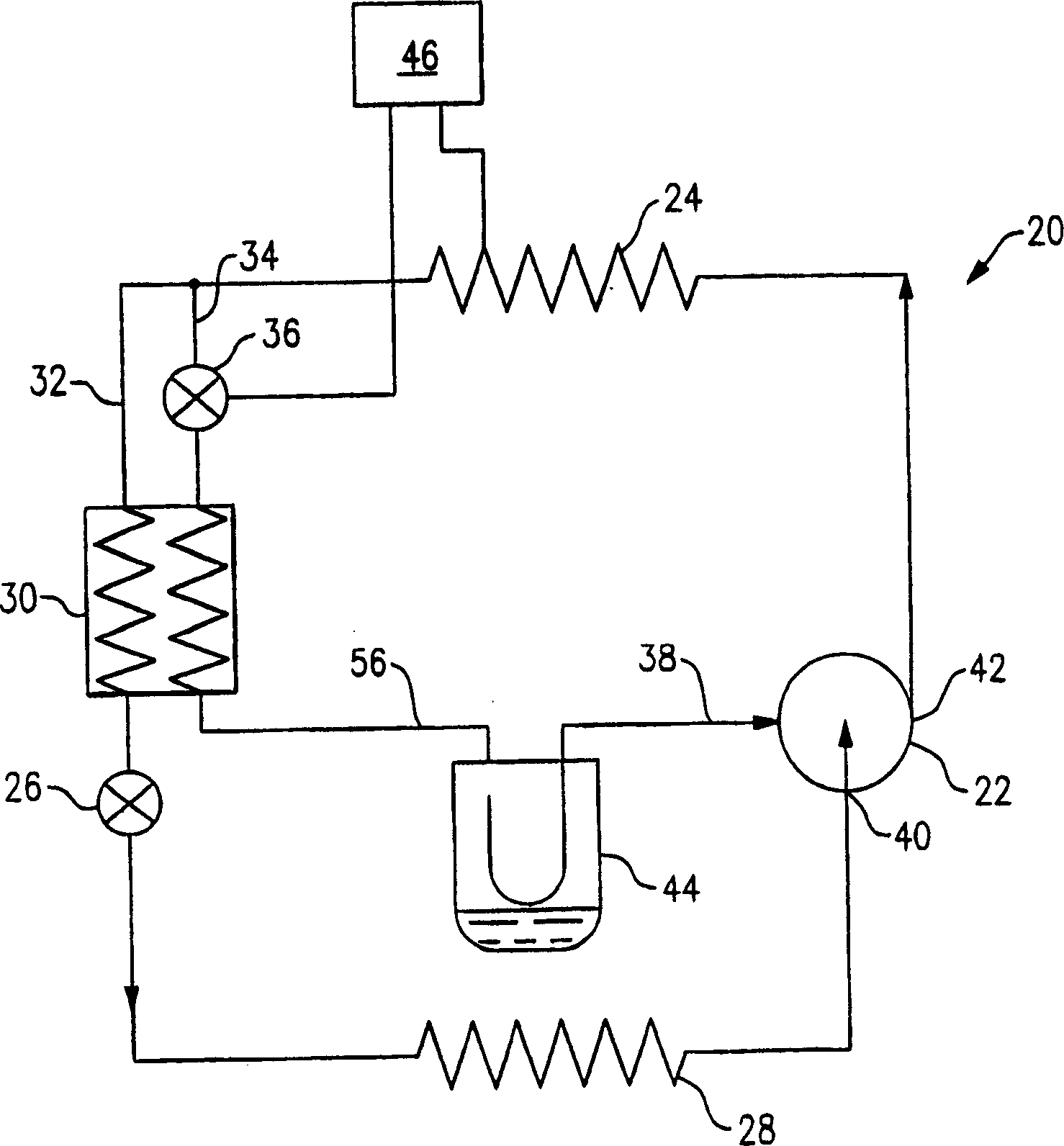

[0013] FIG. 1 schematically shows a prior art refrigeration system 20 . The system 20 includes a compressor 22, a heat sink heat exchanger (gas cooler as a subcritical cycle) 24, a primary expansion device 26, and a heat sink heat exchanger (evaporator) 28, and an economizer heat exchanger 30 . The refrigerant circulates through the circulation system 20 in a closed loop. The refrigerant exits compressor 22 through discharge port 42 at high pressure and high enthalpy. The refrigerant flows through the gas cooler 24 and the refrigerant loses heat to exit with low enthalpy and high pressure. The refrigerant then splits into two flow paths 32 and 34 . The refrigerant in the economizer flow path 34 expands to a low pressure in the economizer expansion device 36 and exchanges heat with the refrigerant in the main flow path 32 located in the economizer heat exchanger 30 to cool the refrigerant in the main flow path. Refrigerant in 32. Refrigerant in the economizer flow path 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com