Sintered neodymium-iron-boron magnet with high coercivity and low remanence temperature sensitivity, and preparation method

A high coercive force, neodymium iron boron technology, applied in the direction of magnetic objects, inductors/transformers/magnet manufacturing, magnetic materials, etc., can solve the problems of increasing the production cost of magnets, reducing the coercive force of magnets, and less natural reserves. Achieve the effect of improving the temperature stability of remanence, high coercive force and improving coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

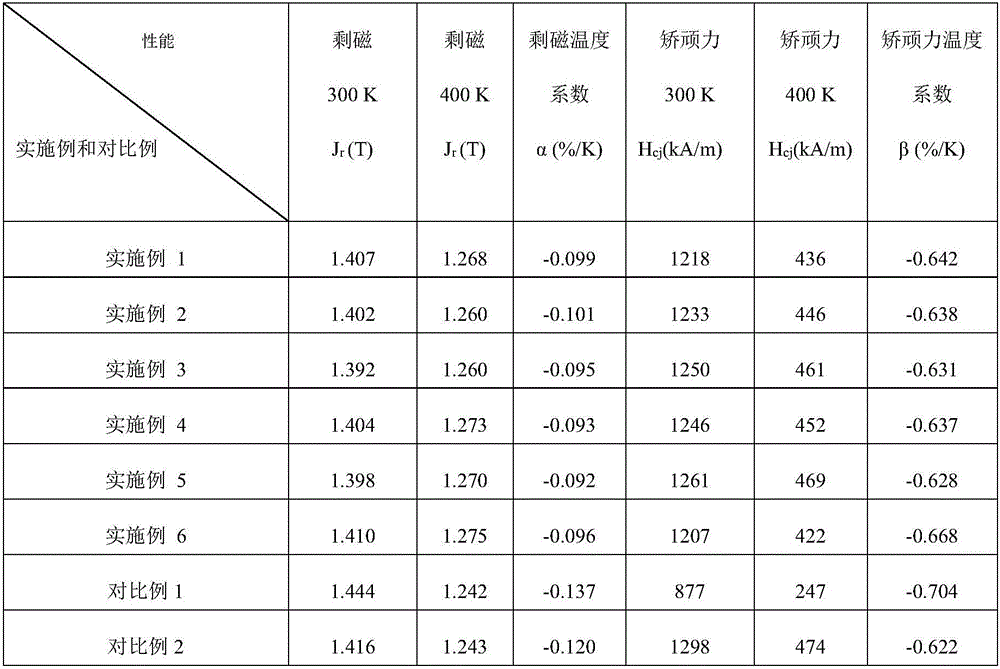

Embodiment 1

[0021] 1) Arc melting alloy ingot Dy 50 Co 50 , Use an electric spark cutting machine to cut the ingot into 0.6mm thin slices, polish off the surface oxide scale with sandpaper, and clean the alloy slices with acetone ultrasonically;

[0022] 2) Process the sintered NdFeB magnet into a size of 15×15×5mm 3 Use sandpaper to polish the surface oxide layer and clean it with acetone ultrasonically;

[0023] 3) Put two pieces of Dy 50 Co 50 The alloy flakes are respectively placed on the upper and lower sides (15×15 sides) of the magnet prepared in step 2, heated to 1000℃, diffused for 4h, and then annealed at 600℃ for 2h, and the vacuum degree is 1×10 -2 Pa.

Embodiment 2

[0025] 1) Arc melting alloy ingot Dy 55 Co 45 , Use an electric spark cutting machine to cut the ingot into 0.5mm thin slices, polish off the surface oxide scale with sandpaper, and clean the alloy slices with acetone ultrasonically;

[0026] 2) Same as Step 2 of Example 1;

[0027] 3) Put two pieces of Dy 55 Co 45 The alloy flakes are respectively placed on the upper and lower sides (15×15 sides) of the magnet prepared in step 2, heated to 900℃, diffused for 1h, and then annealed at 500℃ for 6h, and the vacuum degree is 1×10 -2 Pa.

Embodiment 3

[0029] 1) Arc melting alloy ingot Dy 60 Co 40 , Use an electric spark cutting machine to cut the ingot into 0.3mm thin slices, polish off the surface oxide scale with sandpaper, and clean the alloy slices with acetone ultrasonically;

[0030] 2) Same as Step 2 of Example 1;

[0031] 3) Put two pieces of Dy 60 Co 40 The alloy flakes are respectively placed on the upper and lower sides (15×15 sides) of the magnet prepared in step 2, heated to 760℃, diffused for 8h, and then annealed at 450℃ for 1h, the vacuum degree is 6×10 -3 Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com