Method and device for removing layers in some areas of glass plates

A technology for coating and supporting plates, applied in the directions of coating, cleaning methods and utensils, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

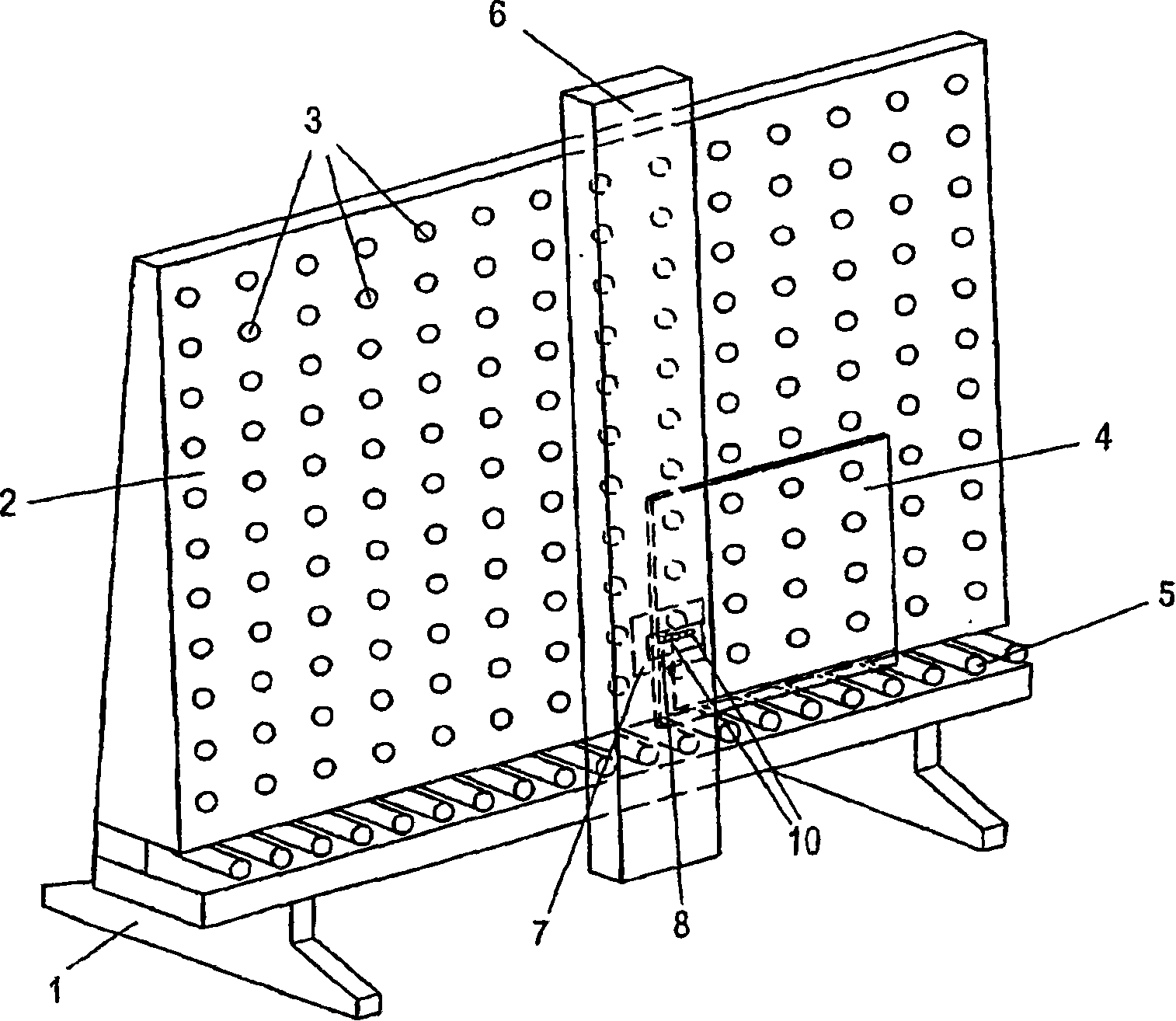

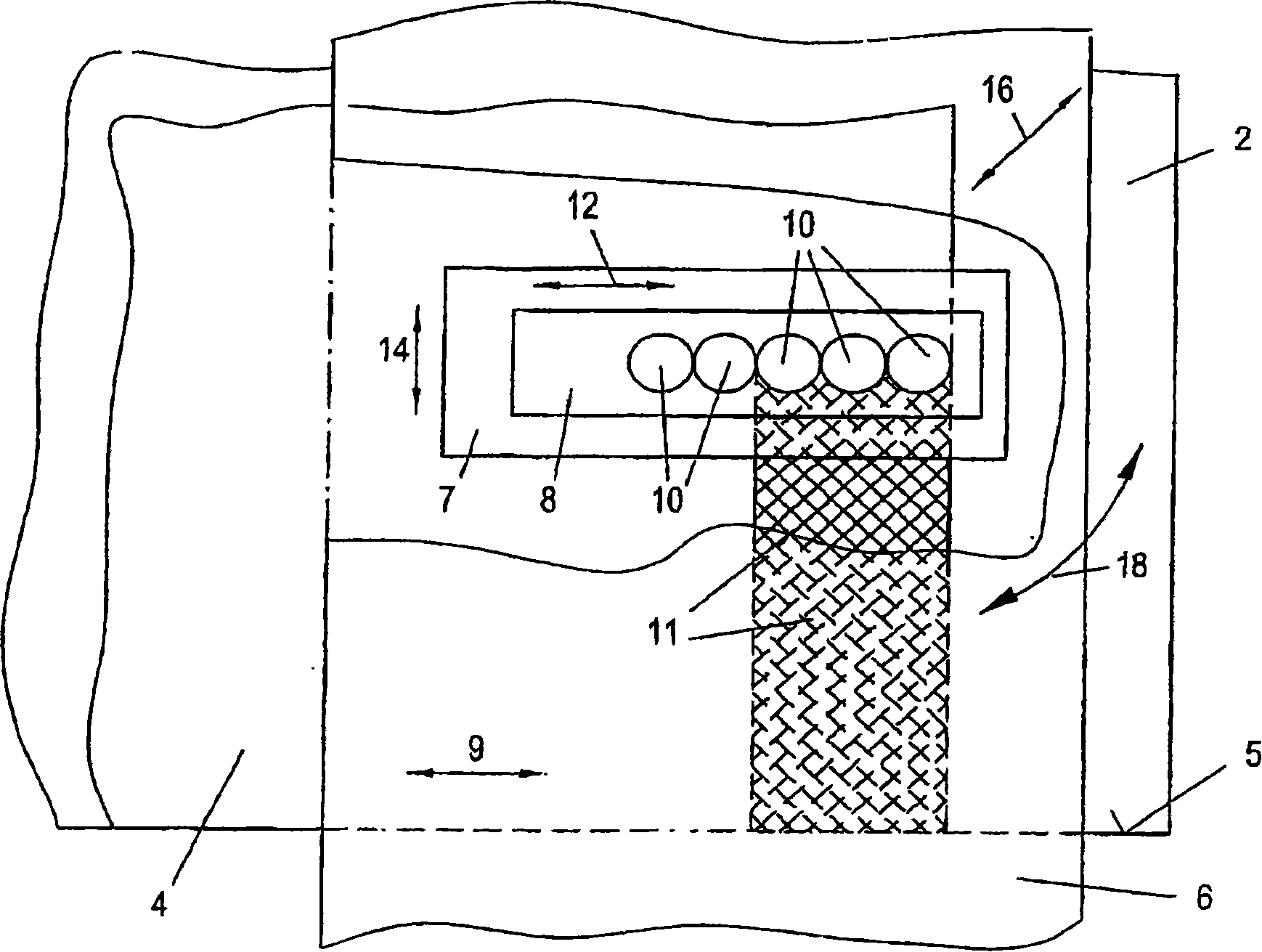

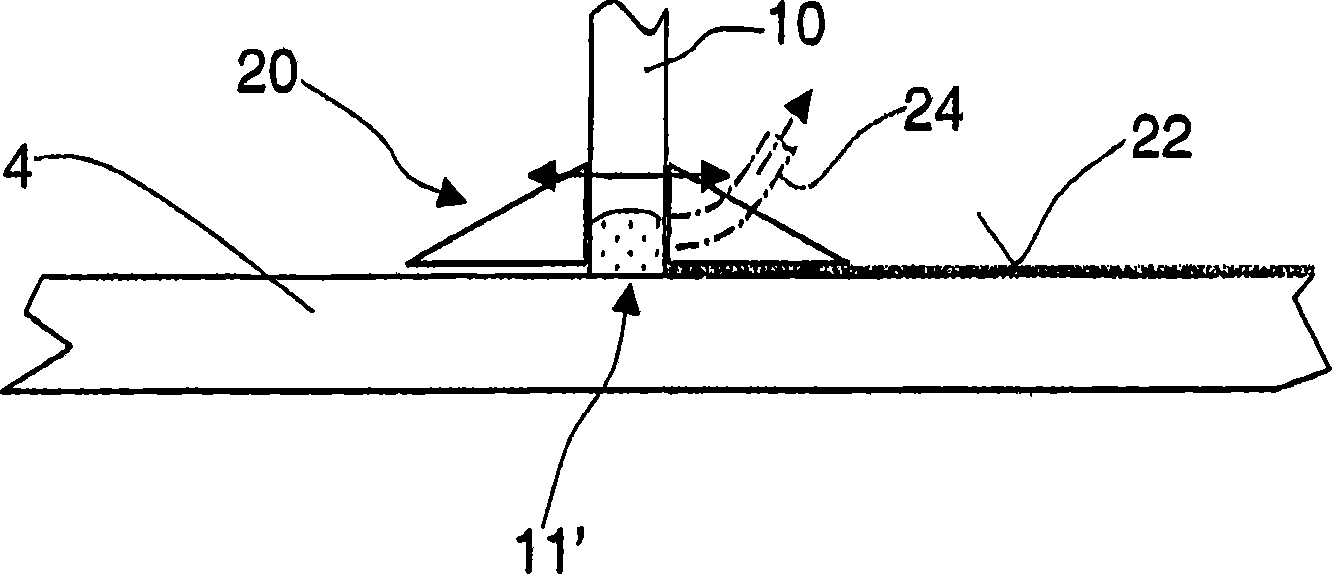

[0091] figure 1 The shown device consists of a base 1 to which a support wall 2 is fastened. As shown, the support wall 2 can be an air cushion wall, for which purpose there are a plurality of openings 3 filled with pressurized air, so that a gap is formed between the support wall 2, for example covered with felt, and the glass plate 4 resting on it. air cushion.

[0092] The type of construction and the position of the support wall 2 are not critical in themselves. Support walls with rollers or rollers or any other sliding surfaces are also conceivable. Of course, the support wall can be different from that shown in the figure, and the processing plane for the substrate can also be laid flat or slightly inclined relative to the horizontal plane.

[0093] For transporting the glass pane 4 , an optional conveying device 5 , such as a conveyor belt or conveyor rollers, is arranged at the lower edge of the support wall 2 . In addition, it is also possible to set a support for...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap