Method for digit controlling arc characteristic under different operation mode and circuit system

A technology of arc characteristics and working conditions, which is applied in the field of arc characteristic control, can solve problems such as difficulty in upgrading, difficulty in changing, and long development cycle, and achieve the effects of improving versatility, reducing development cycle, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

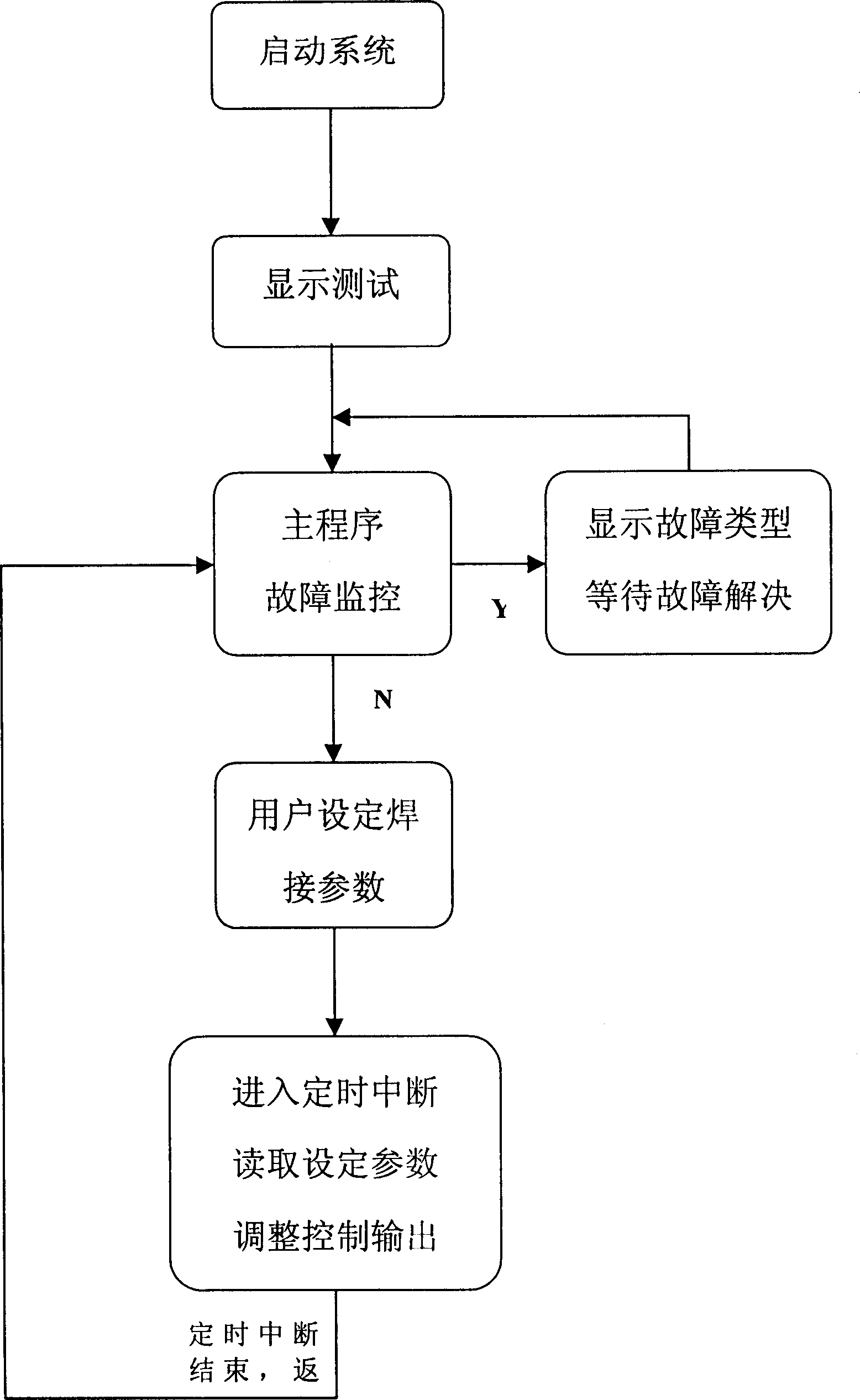

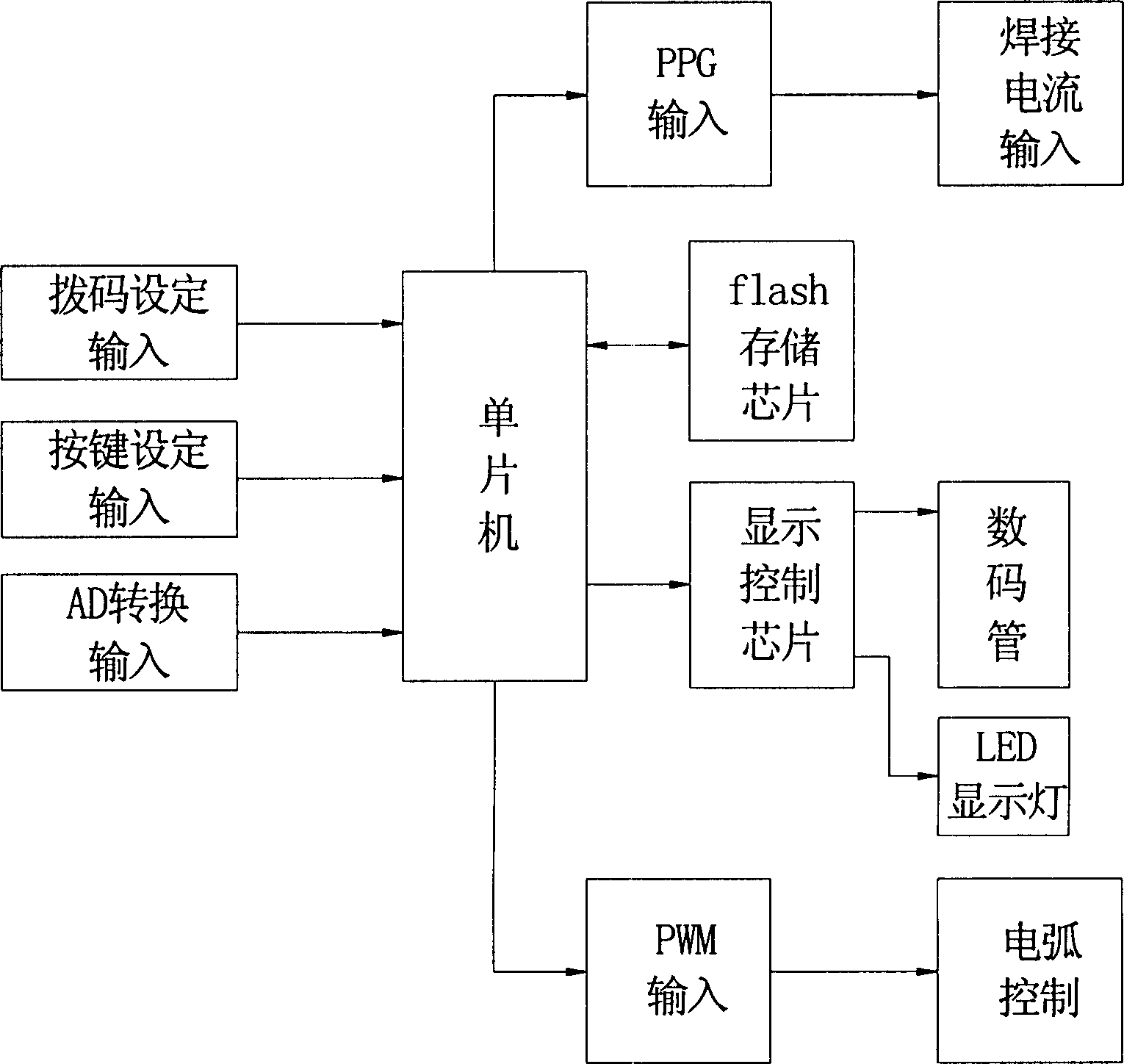

[0031] For example, under manual welding, the thermal arc current control is realized. The user sets the required parameters on the panel, and the single-chip microcomputer system reads the set parameters and adjusts the output according to the set parameters. For example: if the hot start is set to 5, the microcontroller will read the setting of the hot start as 5, and output the hot start current and the hot start time corresponding to 5 in the timer interrupt mode.

Embodiment 2

[0033] For example, the thrust current control is realized in the argon arc welding mode, and the user sets the required parameters on the panel, and the single-chip microcomputer system reads the set parameters and adjusts the output according to the set parameters. For example: if the thrust is set to 5, the microcontroller will read the setting of thrust thermal arcing as 5, and output the thrust current corresponding to 5 in the timing interrupt mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com