Sealed submarine cable

A technology for sealing cables and underwater cables, applied in cable joints, circuits, electrical components, etc., can solve the problems of poor maintainability, high cost, long maintenance cycle, etc., and achieve simple replacement and maintenance, good reliability, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

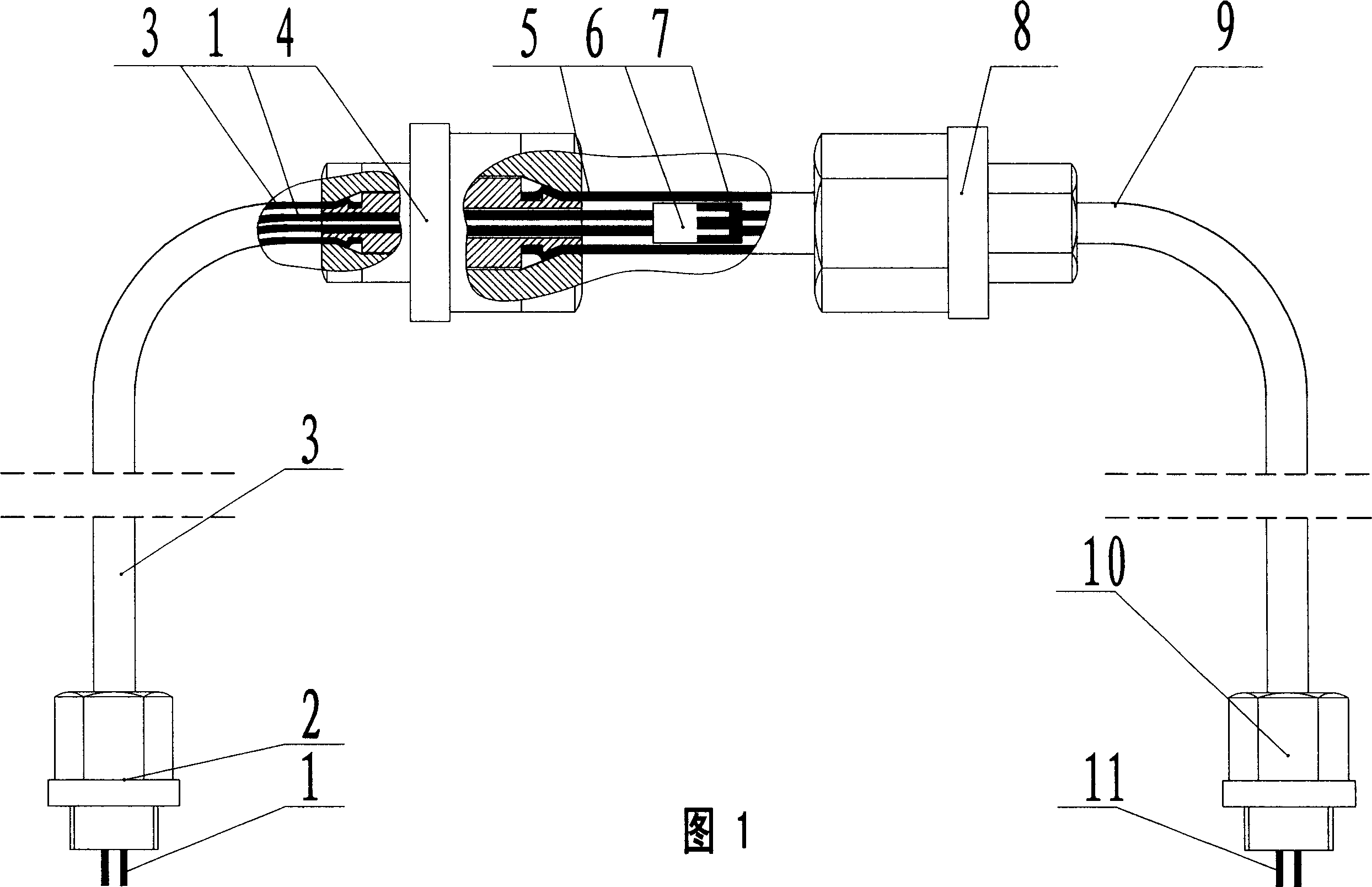

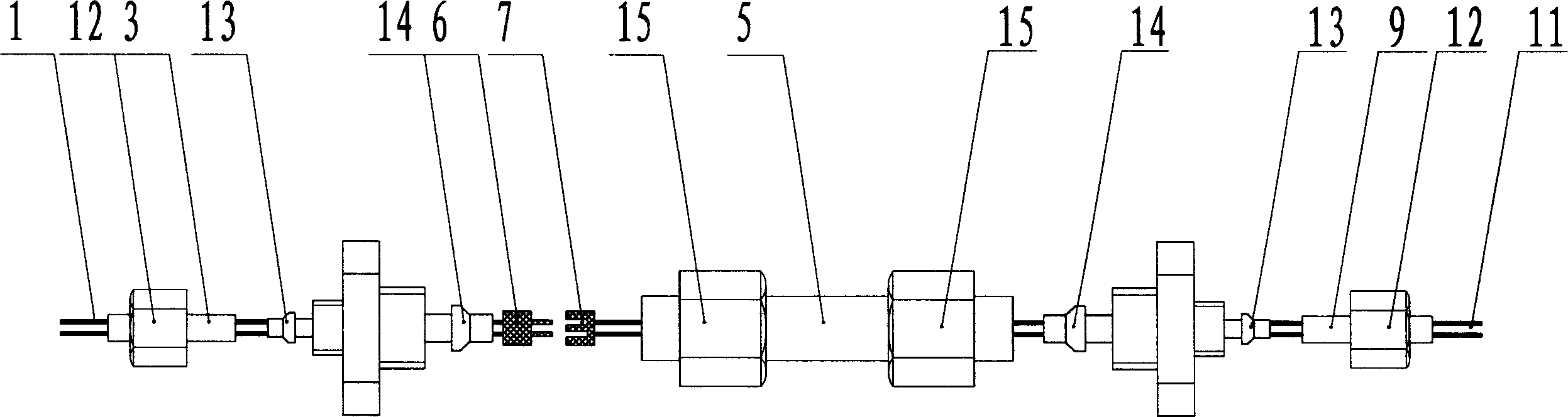

[0018] As shown in Figures 1 and 3, the present invention includes two quick joints 2,10 at the beginning and the end and the sealing thin hoses 3,9 connected thereto and the cables 1,11 therein, and is characterized in that it also includes a pair of variable-diameter quick connectors. The joints 4, 8, and the plug 6 and socket 7 in the thick hose 5 therebetween, and the variable diameter quick connectors 4, 8 are socketed by the sealed thick hose 5.

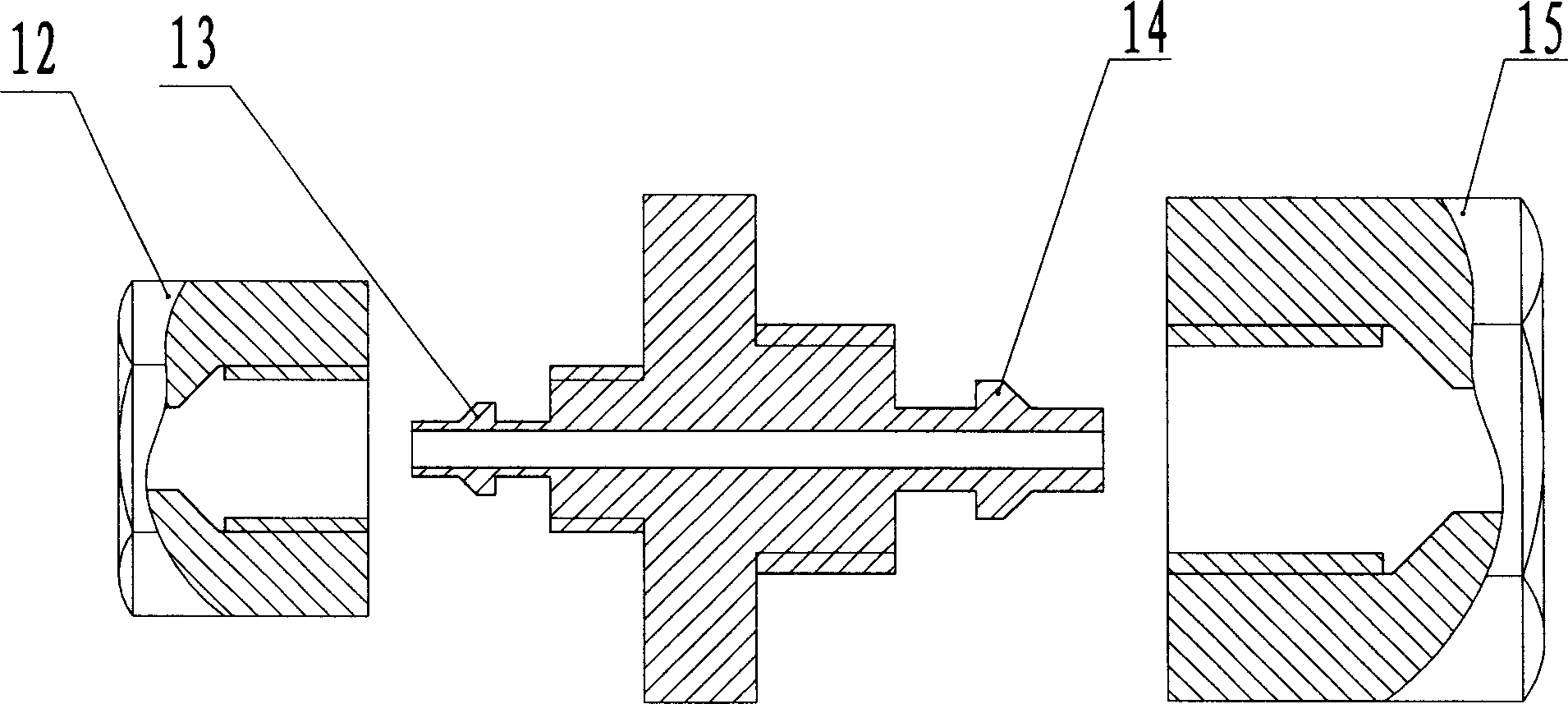

[0019] Such as figure 2 , the essence of the above-mentioned variable-diameter quick connector 4,8 is a quick connector with a small sealing mouth 13 and a large sealing mouth 14 that are screwed with a small nut 12 and a large nut 15 at both ends respectively.

[0020] When in use, the two quick connectors 2 are respectively connected to the sealed chamber body of the existing equipment, which can be connected with the sealing ring by threads, or directly welded together with the chamber body; The end is connected with the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com