Dry gas sealer for compressor with low inlet pressure and liquid-carrying medium

A technology of inlet pressure and gas sealing, which is applied in the sealing of engines, liquid variable displacement machines, mechanical equipment, etc., can solve the problems of easy liquid, low compressor inlet temperature, and seal damage, so as to prevent accumulation and improve reliability sex, to avoid the effect of liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

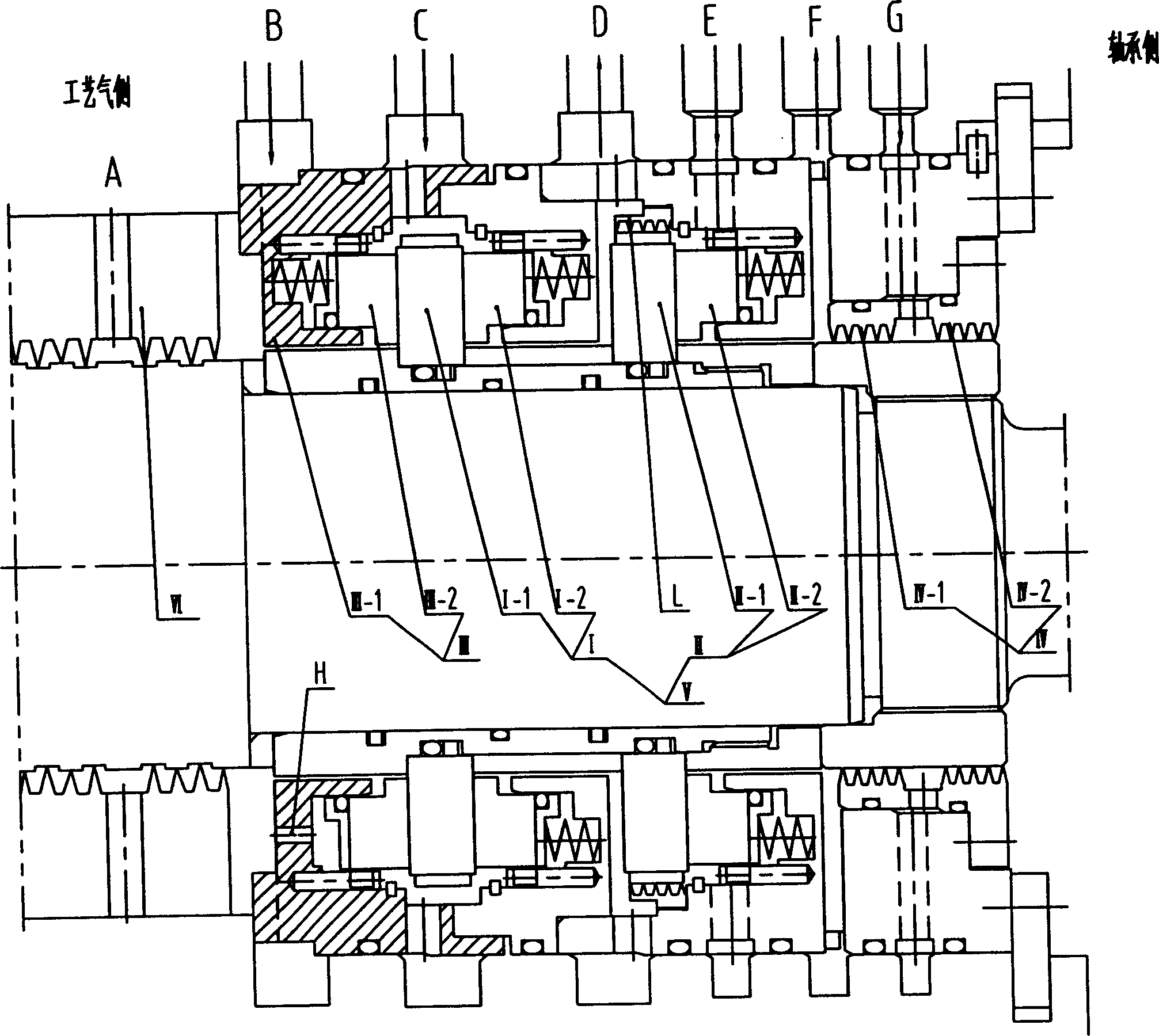

[0030] Example 1: Please refer to image 3 .

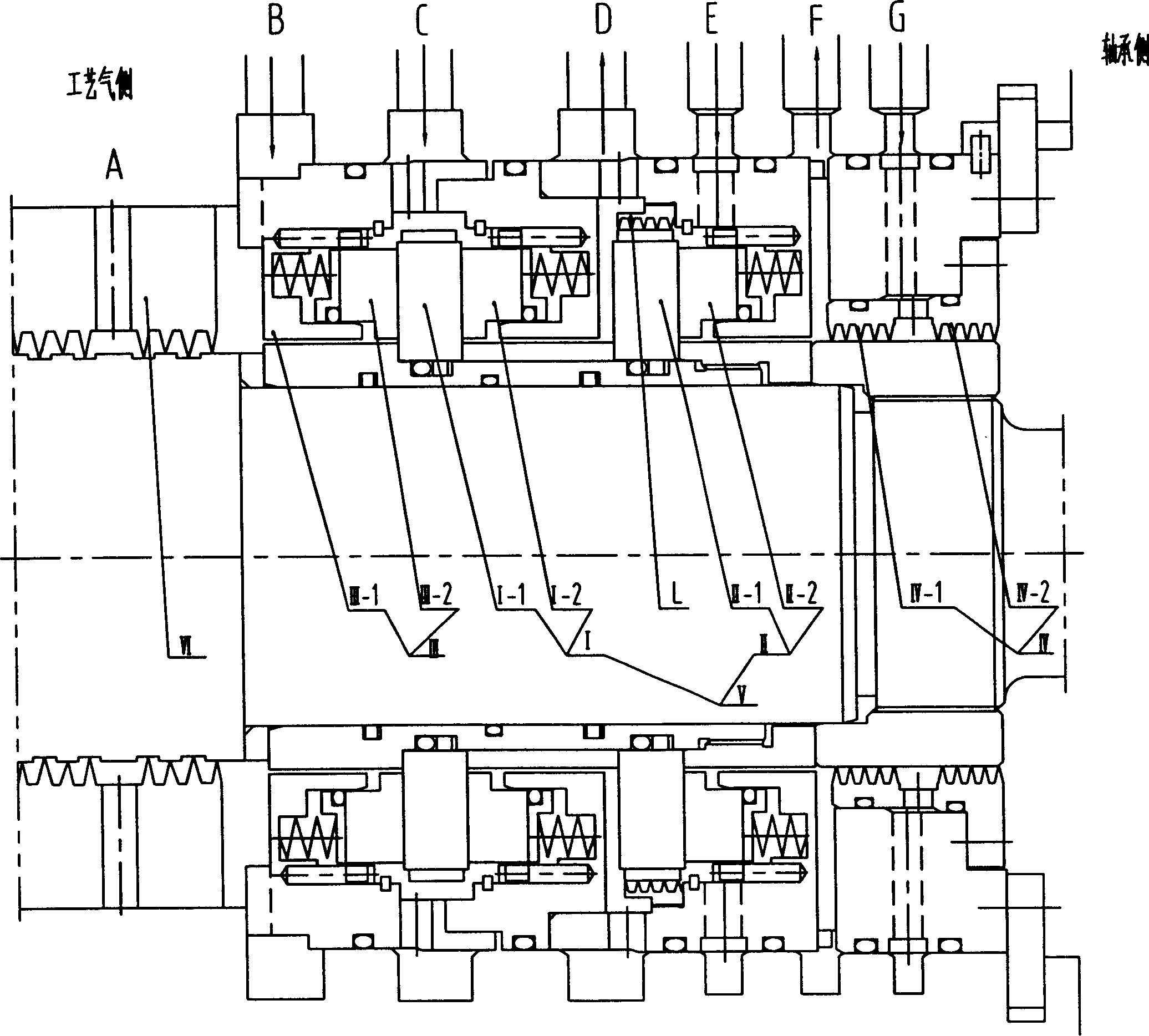

[0031] This example is in figure 1 It is realized on the basis of the known technology shown, that is, the first-stage end face seal I composed of the moving ring I-1 and the static ring I-2 is provided, and the second-stage end face is composed of the moving ring II-1 and the static ring II-2. Seal II, they together form a two-stage serial end face seal V, and a single end face seal III composed of a spring seat III-1 and a static ring III-2 is installed before the first stage end face seal, between the first stage end face seal and the second stage There is a labyrinth seal L between the two-stage end face seals, and a rear isolation seal IV is connected behind the two-stage series end face seals, and IV-1 and IV-2 respectively represent the labyrinth of the rear isolation seal (rear labyrinth) The improvement lies in the fact that the front end of the spring seat III-1 with a single end face seal installed before the first st...

Embodiment 2

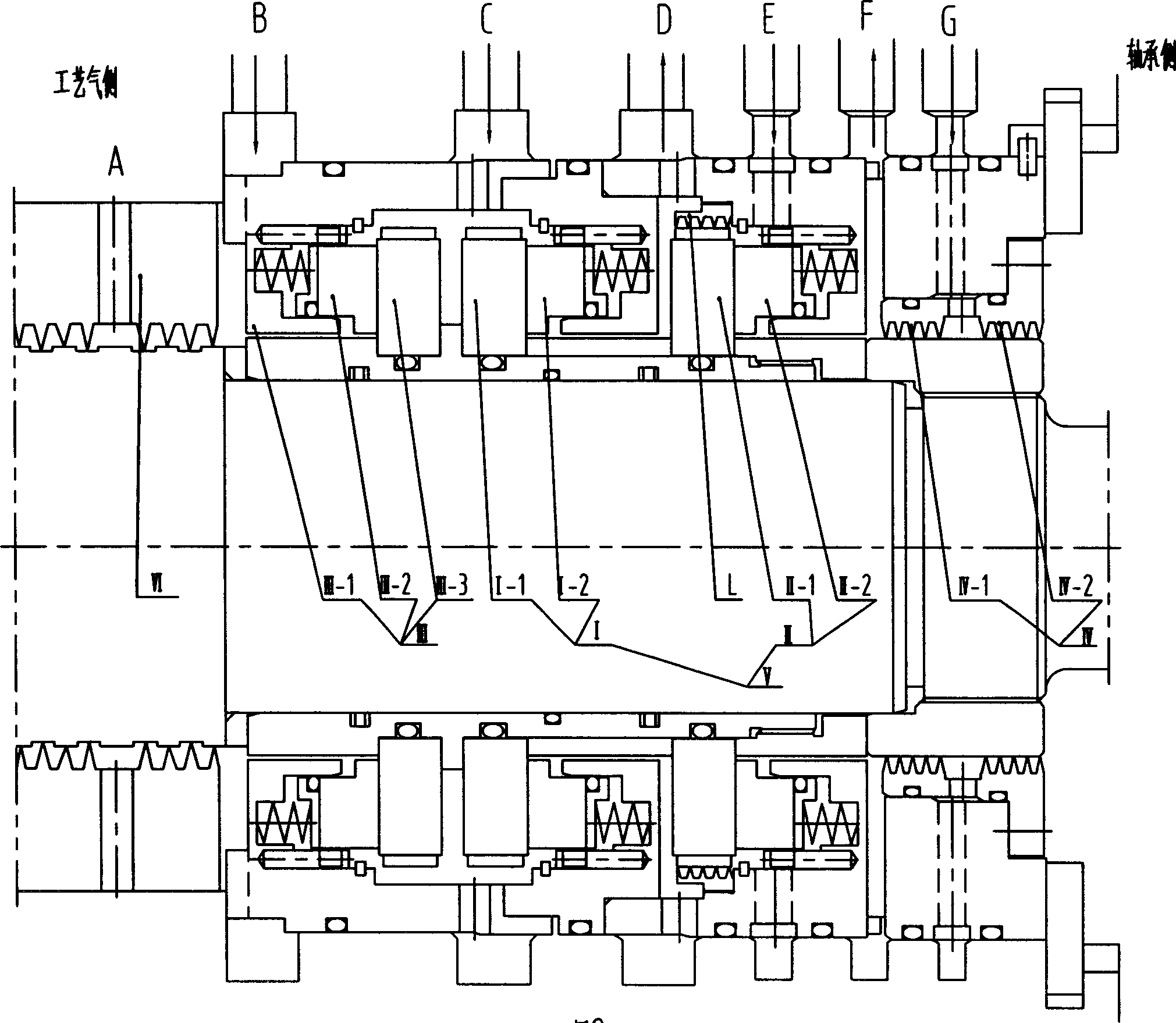

[0032] Example 2: Please refer to Figure 4 .

[0033] This example is in figure 2 It is realized on the basis of the known technology shown, and the difference between the known part of its structure and the first embodiment is that a Moving ring III-3, the improved part related to the content of the present invention is completely the same as that of the first embodiment.

Embodiment 3

[0034] Example 3: Please refer to Figure 5 and Figure 7 .

[0035] This example is in figure 1 Realized on the basis of the known technology shown, the known part of its structure is exactly the same as that described in Embodiment 1, and its improvement is that the outer threaded connection of the spring seat III-1 is as follows Figure 7 Shown consists of a housing 1 with an air inlet, a spherical valve flap 3 installed at the air inlet of the inner cavity of the housing, a screw plug 4 with an air outlet that is threaded at the front end of the housing, and a screw plug 4 installed in the inner cavity of the housing. The miniature one-way valve formed by the spring 2 connected between the spherical disc and the plug, has an air inlet hole leading to the air inlet of the miniature one-way valve housing on the inner side of the spring seat, and the miniature one-way valve The number of valves can be determined according to specific application requirements. This type of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com