Liquid-liquid heat exchanger

A technology of heat exchangers and exchangers, applied in heat exchange equipment, water heaters, fluid heaters, etc., can solve the problems of worsening concentricity, high cost, and many working hours, and achieve the effect of reducing working hours and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

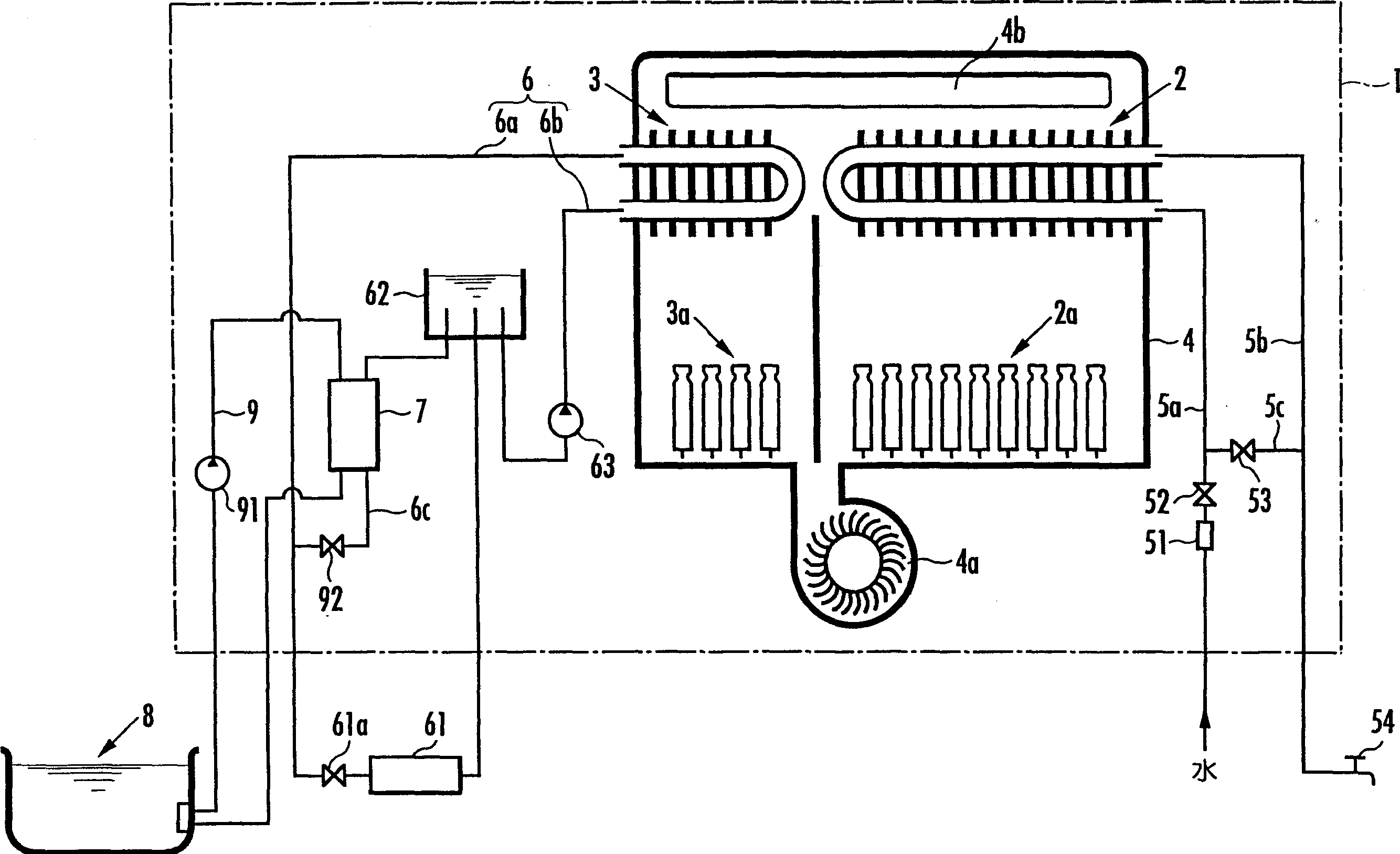

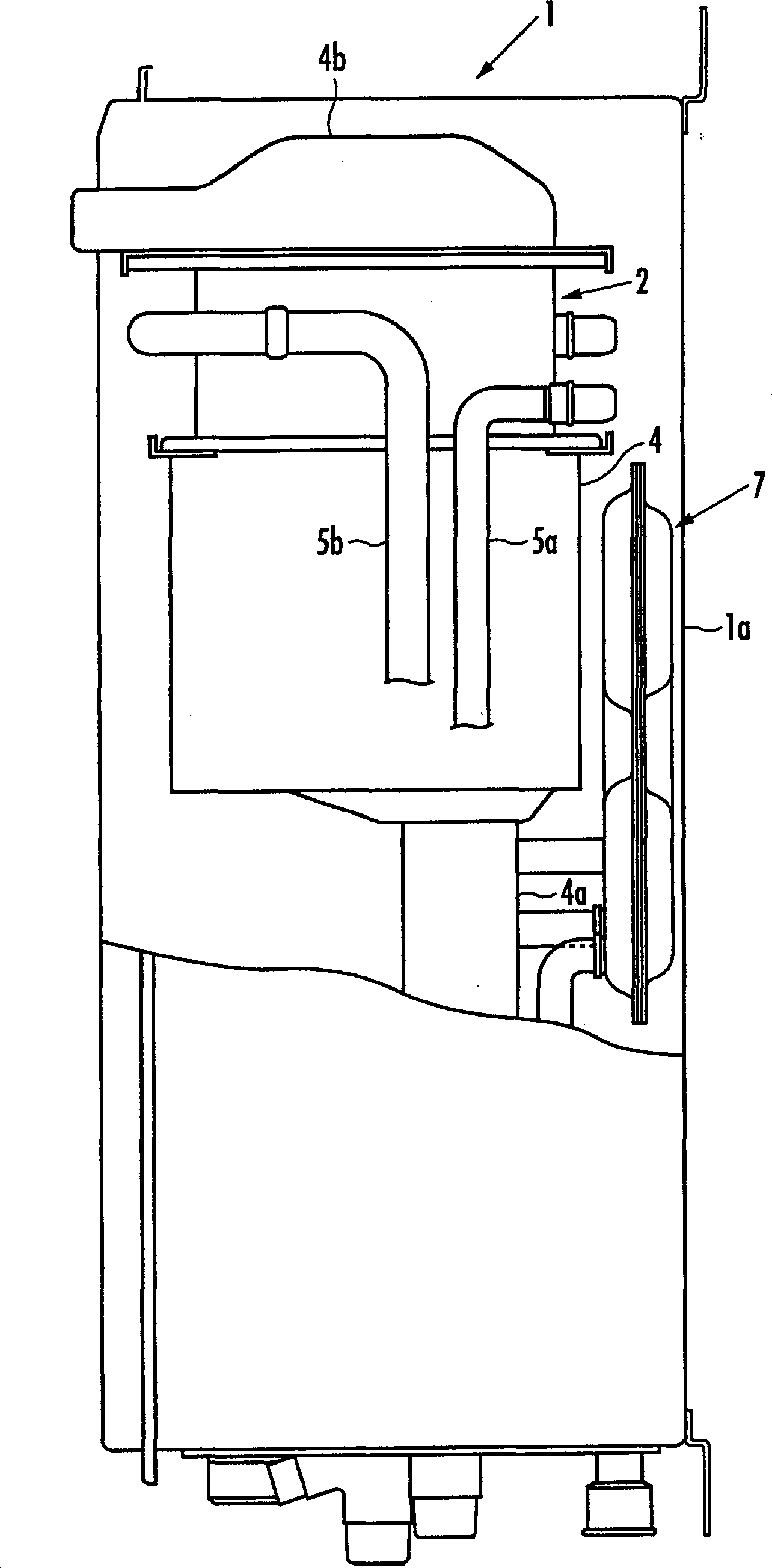

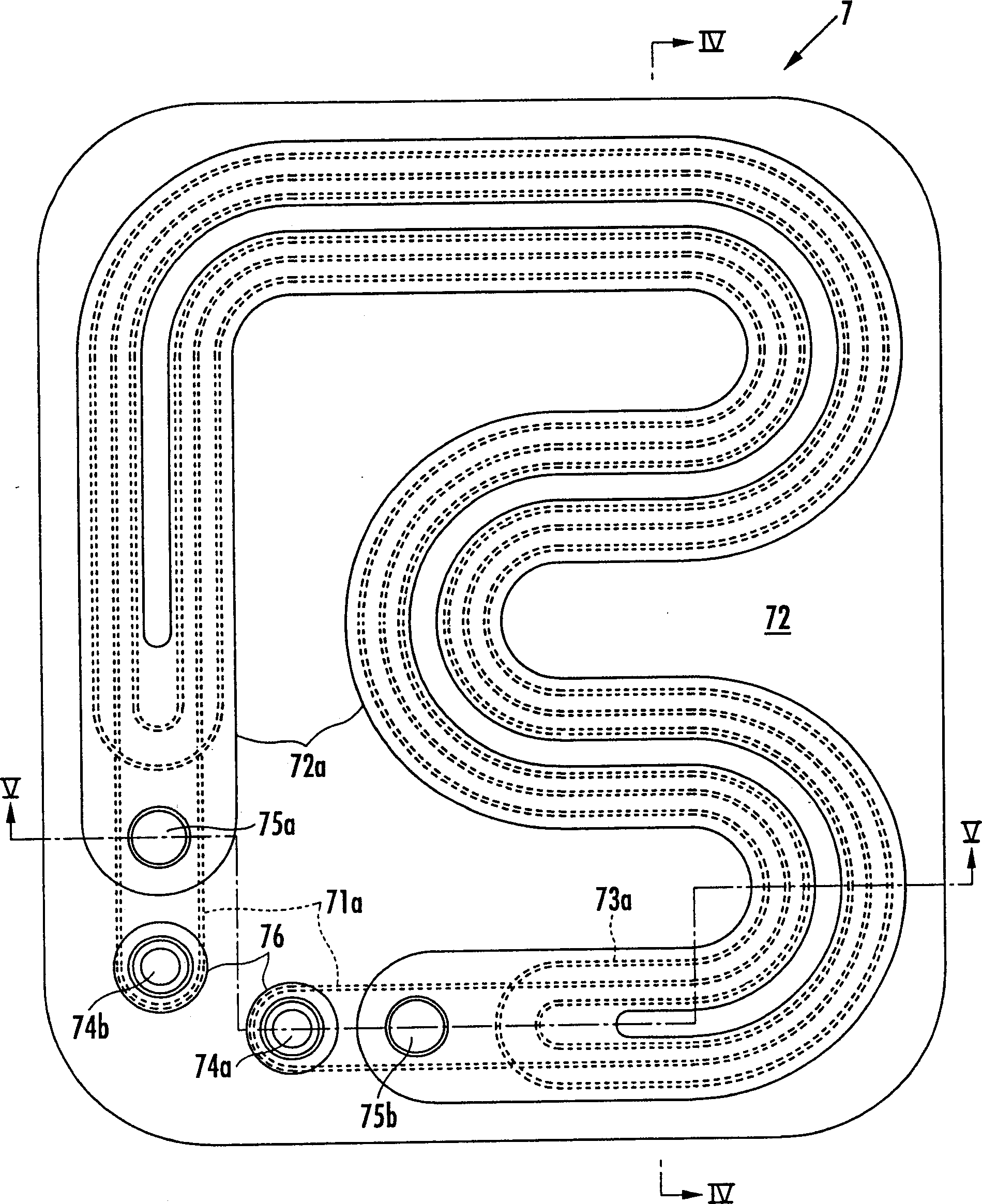

[0018] refer to figure 1 , 1 denotes a heat source machine including the heat exchanger 2 for hot water supply and the heat exchanger 3 for heating. The two heat exchangers 2 and 3 for hot water supply and heating are arranged side by side on the upper part of the tank body 4 arranged in the heat source machine 1 . At the bottom of the tank body 4, a hot water supply burner 2a as a heat source of the hot water supply heat exchanger 2 and a heating burner 3a as a heat source of the heating heat exchanger 3 are arranged side by side. 4, the combustion of each burner 2a, 3a is carried out using the air supplied from the blower 4a below it as combustion air. In addition, an exhaust passage 4b for exhausting combustion exhaust gas passing through the respective heat exchangers 2 and 3 is provided above the tank body 4 .

[0019] The water supply path 5 a on the upstream side and the outlet hot water path 5 b on the downstream side are connected to the heat exchanger 2 for hot w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com