Safety helmets

A helmet and safety technology, which is applied in the field of safety helmets with polymer composite sandwich structures, can solve the problems of manufacturing costs, increasing complex processing steps, etc., and achieve the effect of reducing the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

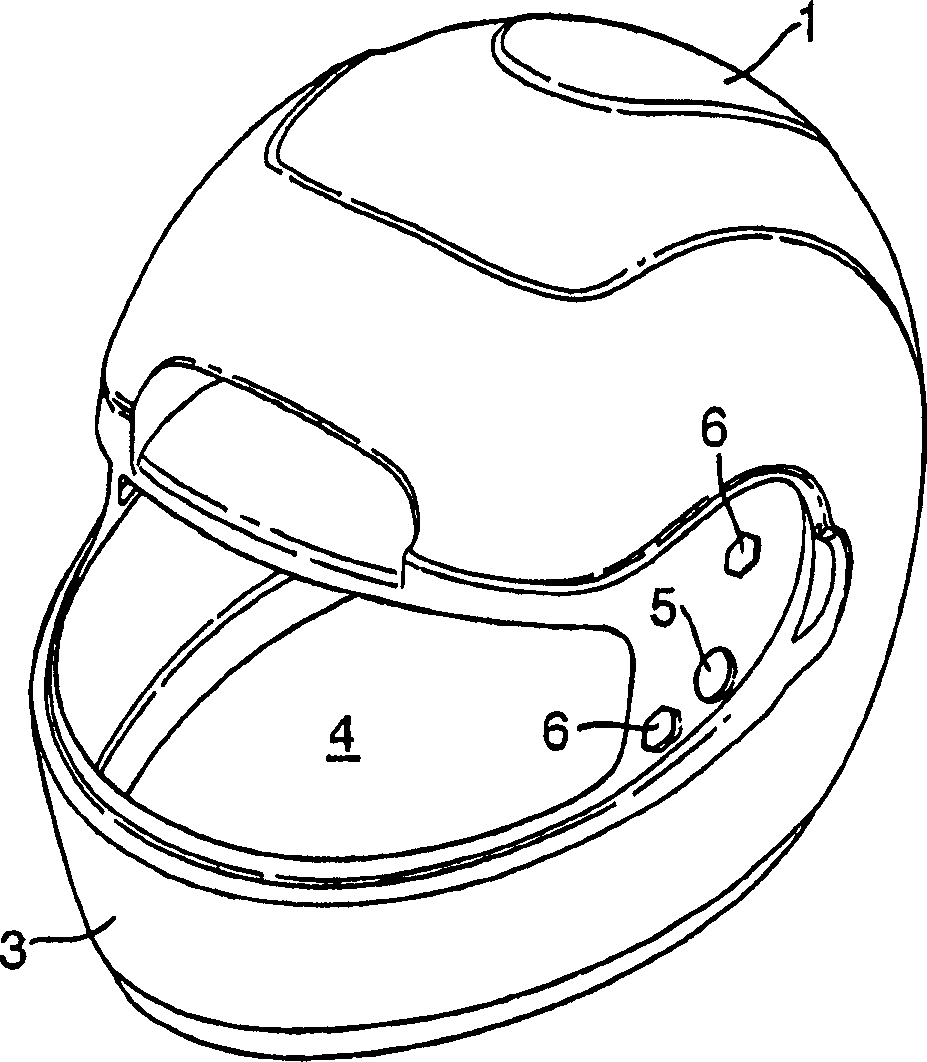

[0065] figure 1 Indicates the fibre-reinforced first polymer layer. A concave mold (not shown) will have a series of raised and lower relief patterns which will create the surface shape of the first (outer) layer. The key features of this layer are the dome section comprising the top vent recess 1 and the front vent recess 2, this recess also serves as a means of aligning the energy dissipating material in the female mold. There is also a vent hole in the chin bar area 3, the vent holes 1, 2, 3 are designed to ensure that enough air is able to circulate inside the finished helmet. A goggle section (not shown) will be located in the cut-out portion 4 and it will be fixed and hinged at corresponding anchor points 6 on either side of the helmet. A chin strap (not shown) will be fastened at the mounting hole 5, with an identical fastening point on the other side of the helmet. The mounting holes 5, 6 are ground during the finishing stage of the final helmet to ensure correct al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com